Micro-nano nested groove surface drag reduction structure based on vortex drive design

A micro-nano, scale technology, used in heat-reducing structures, mechanical equipment, engine components, etc., can solve problems such as increased total resistance and difficulty in reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

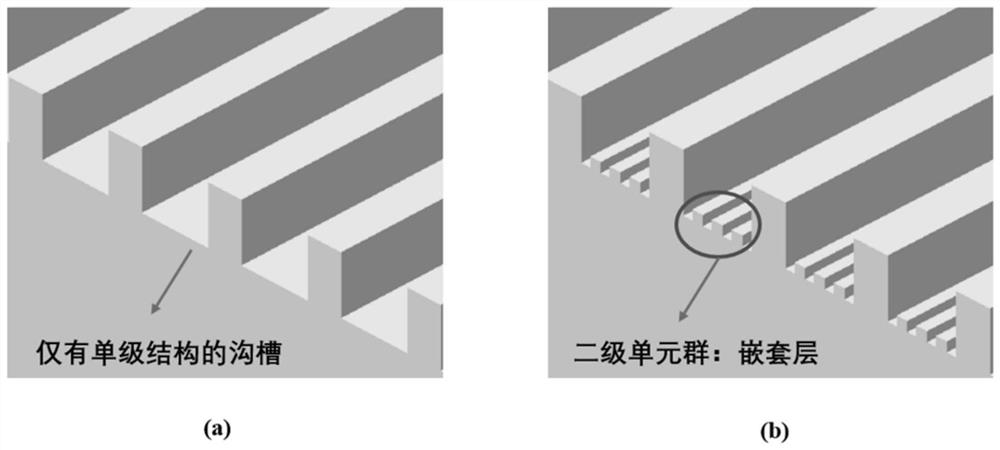

[0015] Example 1 A novel micro-nano scale nested groove surface drag reduction structure designed by vortex drive

[0016] 1. Research on drag reduction mechanism of grooved surface and "vortex drive design" theory

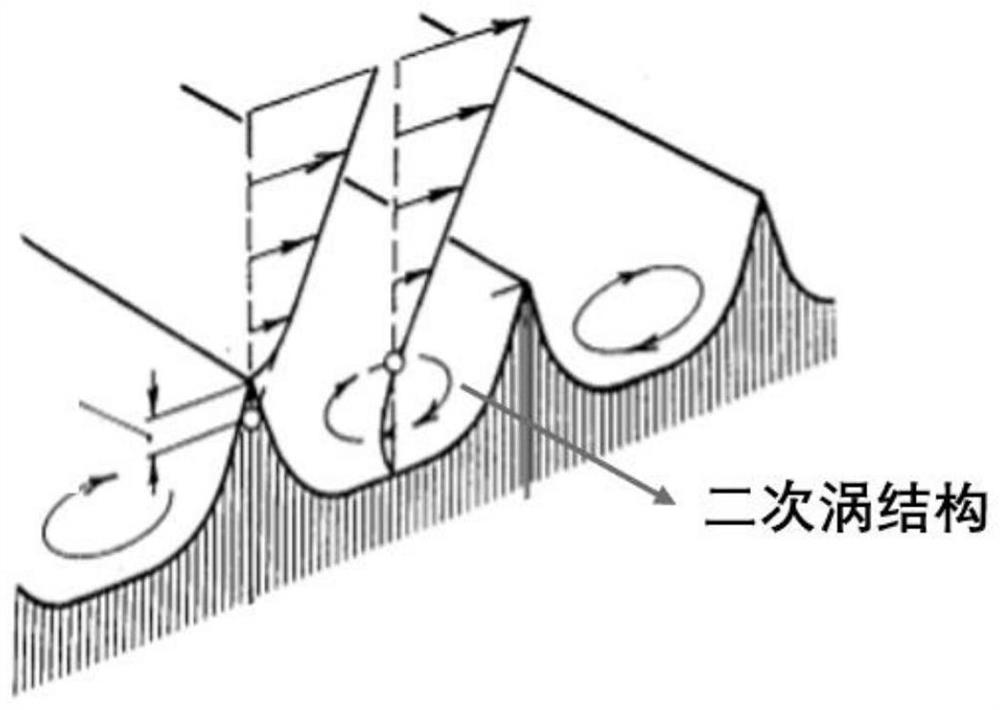

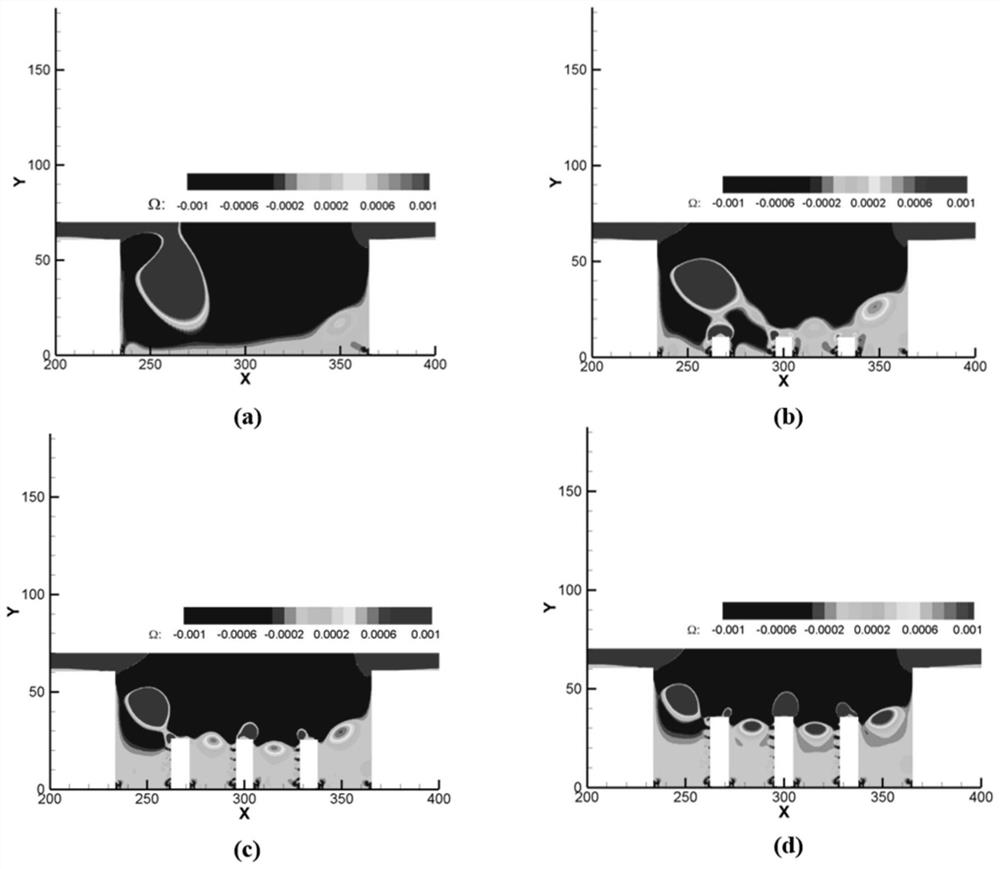

[0017] The protrusion height theory is widely used to study the drag reduction mechanism of grooved surface structures. The protrusion height of the cross flow was first proposed by Bechert, such as figure 1 As shown, it is the distance from the top of the groove to the equivalent smooth surface of the groove through a conformal transformation. The secondary vortex structure is formed in the groove, which increases the thickness of the viscous bottom layer in the boundary layer flow, reduces the average velocity gradient near the wall surface, and reduces the surface frictional resistance. The change of vorticity distribution and flow characteristics drives the change of velocity distribution and shear stress in the groove, and the local reverse shear caused by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com