Material stacking equipment

A material and palletizing technology, applied in the field of material palletizing equipment, can solve problems such as difficulty in ensuring the uniformity of centrifuge paper laying and reducing work efficiency, and achieve the effects of ensuring uniformity, improving efficiency, and improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

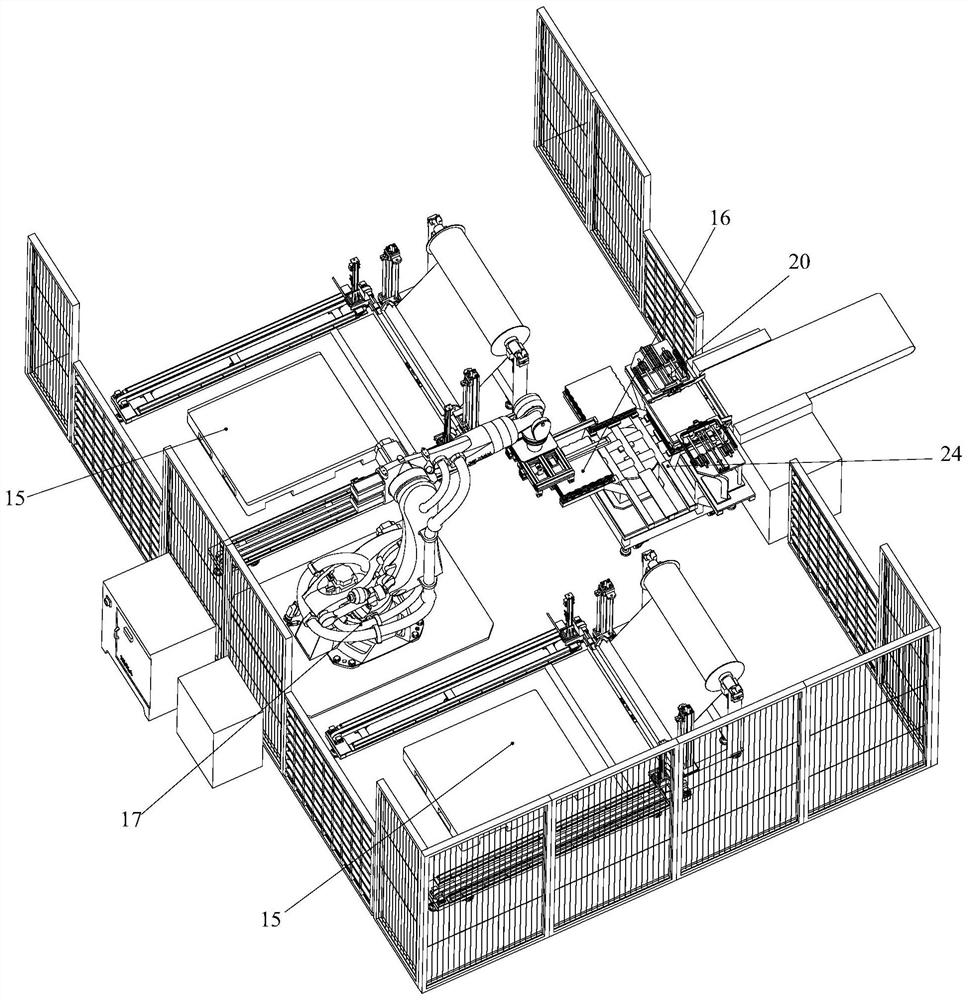

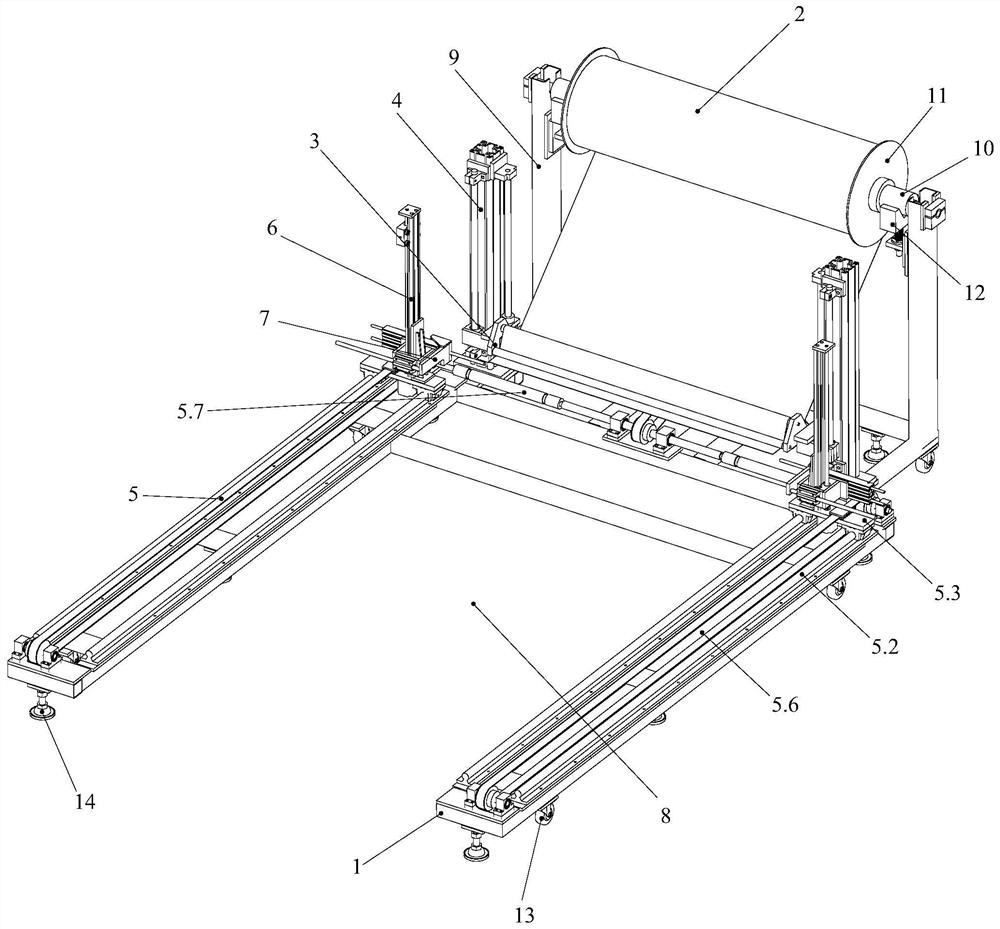

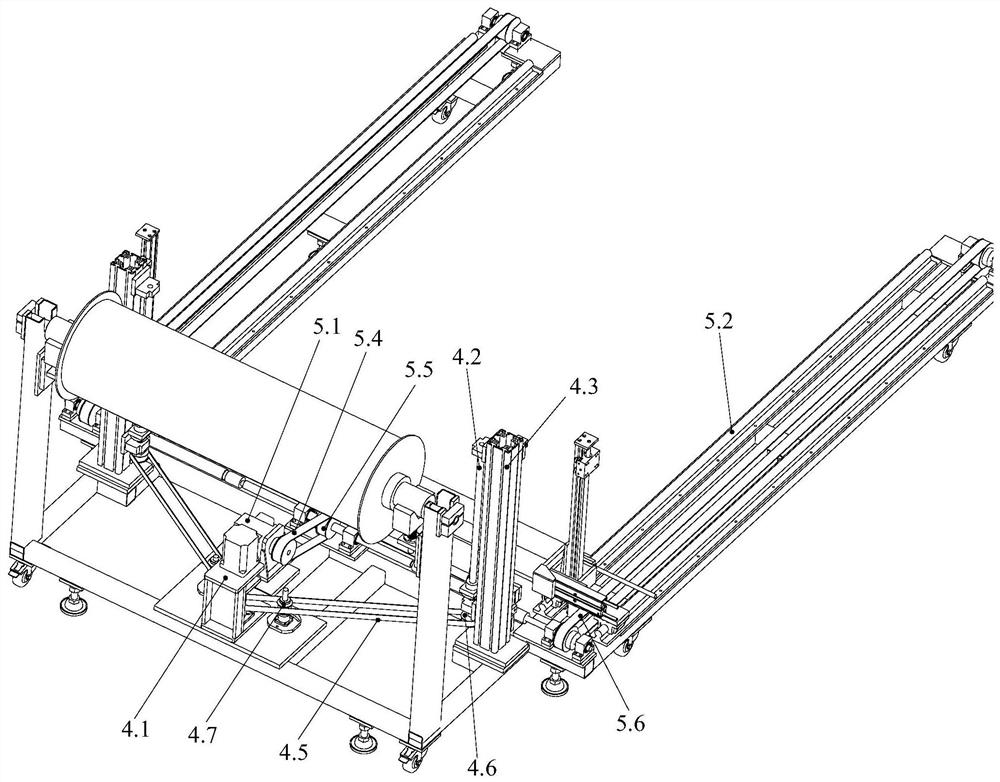

[0056] Such as Figures 1 to 14 As shown, the material stacking equipment of the present invention includes a material stacking and steering mechanism, a robot 17 and two paper laying mechanisms, wherein the material stacking and steering mechanism includes:

[0057] Frame 18; Frame 18 is provided with the belt brake universal wheel 13 and foot cup 14 that are convenient to move;

[0058] A conveying device 20 for conveying the material 16. Below the conveying device 20 is a stacking station 21. The outside of the conveying device 20 is a discharging station 22. Between the stacking station 21 and the discharging station 22 It also includes an empty check station 23;

[0059] A steering device 24 with a bracket 24.1, the steering device 24 controls the bracket 24.1 to switch between the stacking station 21, the emptying station 23 and the discharging station 22 in a rotating manner; the emptying station of the present invention Position 23 has two functions: one is to ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com