Preparation method for improving phycoerythrin yield

A technology for phycoerythrin and yield, applied in the direction of microorganism-based methods, biochemical equipment and methods, chemical instruments and methods, etc., can solve the problems of high sugar content in large red algae, difficulty in crushing and releasing phycoerythrin, separation and purification Problems such as difficult procedures, to achieve the effect of lowering the threshold of production technology, easy to achieve, and simple procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

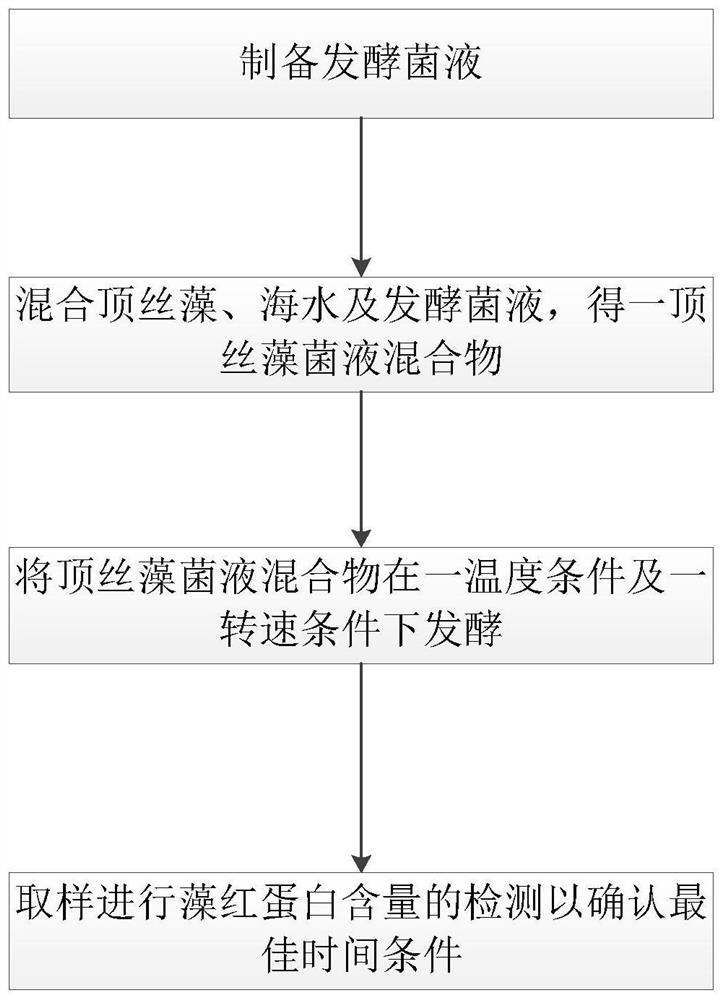

[0033] The preparation method for improving the yield of phycoerythrin provided by the present invention, its embodiment comprises:

[0034] Step 1, mixing an Acremonas, a fermentation broth containing Pseudoalteromonas thalassemia and a seawater to obtain a mixture of Acremonas broth, wherein the OD of the fermentation broth is 600 The value is 0.9~1.1, the OD of the fermentation broth 600 The value is preferably 1, wherein the mixing ratio of the Acrometa: the fermentation broth: the seawater is 2(g):1(mL):1(mL);

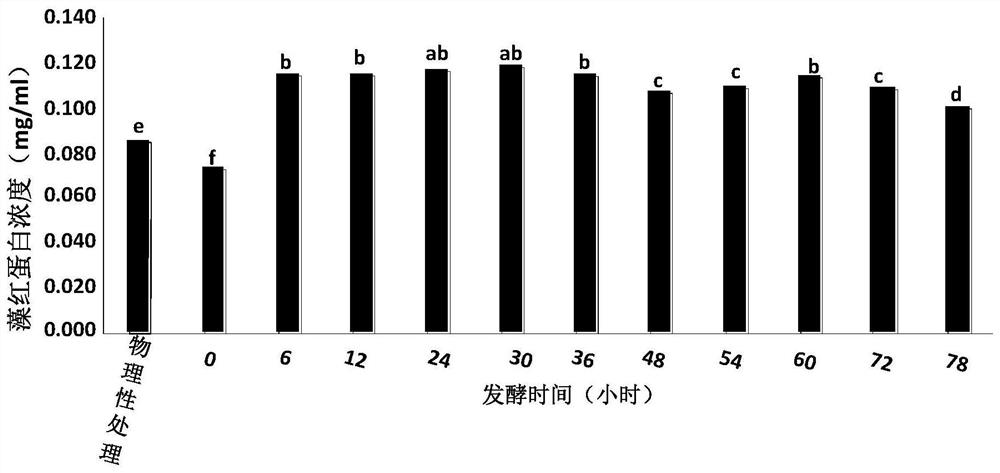

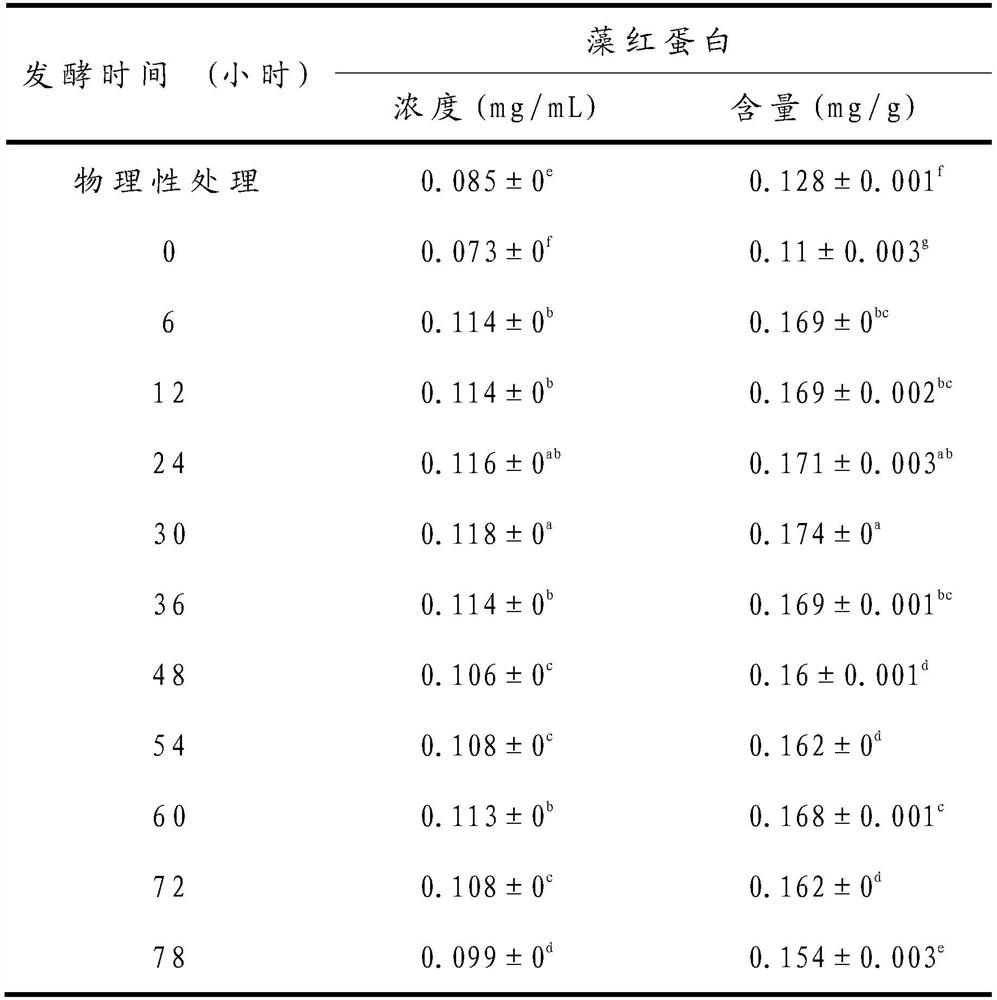

[0035] Step 2, fermenting the Acromycetes bacterium liquid mixture under one time condition, one temperature condition and one rotational speed condition, so that the Acrometrix algae is broken and released phycoerythrin, wherein the time condition is 6-78 hours, and the time condition It is preferably 6-36 hours, the best time condition is 24-30 hours, the temperature condition is 20-25°C, the best temperature condition is 22°C, the rotation speed condition is 1...

Embodiment 1

[0036] Embodiment one, preparation fermented bacteria liquid

[0037] After defrosting the cryopreserved Pseudoalteromonas marinum, take 100 μL of the bacterial liquid to the solid medium (Marineagar) to smear the plate to activate the strain. After culturing at 22°C for 12 hours, use 1 mL of phosphate buffered saline (Phosphate buffered saline Pseudoalteromonas marinum, PBS) was rinsed and inoculated into 50 mL of liquid medium (Marinebroth), and cultured in a liquid state at 22°C and 300 rpm for 12 hours, and then the absorbance at 600 nm was detected by a spectrophotometer. When OD 600 When the value is 0.9-1.1, it can be used as the fermentation broth for the fermentation of Acrometrix algae.

Embodiment 2

[0038] Embodiment two, acrometa fermenting process

[0039] Take an acremonium and add it into a seawater, and then add the fermentation broth prepared by the method described in Example 1 to obtain a mixture of acremonium broth. Ferment the Acrometrix bacterium liquid mixture under one temperature condition and one rotational speed condition, so that the Acrometrix algae is broken to release the water-soluble phycoerythrin, and it is fermented at 0, 6, 12, 24, 30, 36, 48, 54, Samples were taken at 60, 72 and 78 hours for detection of phycoerythrin content. Wherein, the Acrometrix: the seawater: the mixing ratio of the fermentation liquid is 2 (g): 1 (mL): 1 (mL); wherein the seawater is artificial seawater or natural seawater; wherein the temperature condition is 20- 25°C, the optimal temperature condition is 22°C; the rotational speed condition is 100-500rpm, the preferred rotational speed condition is 200-400rpm, and the optimum rotational speed condition is 300rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com