Printing and dyeing process of antistatic fabric and antistatic fabric

An antistatic fabric, printing and dyeing process technology, applied in the direction of fabric elongation, fabric surface trimming, heating/cooling fabric, etc., can solve the problems of conductive fiber conductive layer damage, antistatic performance decline, etc., to meet the coloring requirements , Avoid damage to the conductive thread and preserve the electrostatic properties of the fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A printing and dyeing process for antistatic fabrics, which comprises the following steps:

[0053] S1. Cooking and bleaching: new standard of antistatic fabric C20*16 / 128*60 carbon black grid 1*1 inlaid with static silk (the point-to-point resistance value of the gray cloth is 2.8*10 5 ), through seam turning and connection, in the bleaching liquid, through two dipping and two rolling treatments, the liquid rolling rate is 90%, and the vehicle speed is 80 m / min; 2 o 2 2.5g / l; caustic soda 10g / l; steam in a steam box at 70°C for 60 minutes, wash with hot water, rinse with seven grids of hot water, and dry after washing;

[0054] S2. Heat setting: The fabric after boiling and bleaching is set at high temperature, the setting temperature is 210°C, and the cloth is fed in reverse; the width of the heat setting fall cloth is 158cm, and the heat setting fabric is obtained after the treatment

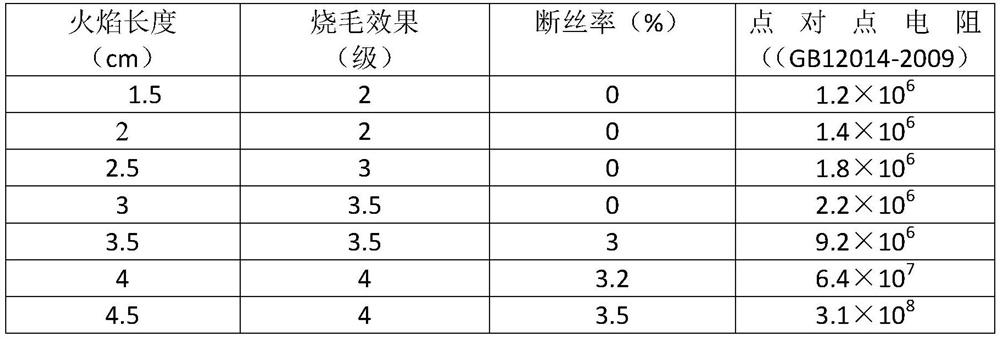

[0055] S3. Singeing: remove the fuzz on the surface of the heat-setting fabric ...

Embodiment 2

[0059] A printing and dyeing process for antistatic fabrics, which comprises the following steps:

[0060] S1. Cooking and bleaching: the antistatic fabric cvc32*32 / 130*70*63 carbon black mesh 1.0 new standard inlaid with static silk (the point-to-point resistance value of the gray cloth is 4.1*10 5 ), connected through seam turning, through two dipping and two rolling treatments in the bleaching liquid, the liquid rolling rate is 80%, and the vehicle speed is 90 m / min; 2 o 2 2.5g / l; caustic soda 10g / l; steam in a steam box at 70°C for 60 minutes, wash with hot water, rinse with seven grids of hot water, and dry after washing;

[0061] S2. Heat setting: The fabric after boiling and bleaching is set at high temperature, the setting temperature is 210°C, and the cloth is fed in reverse; the width of the heat setting fall cloth is 158cm, and the heat setting fabric is obtained after the treatment

[0062] S3. Singeing: remove the fuzz on the surface of the heat-setting fabric ...

Embodiment 3

[0066] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0067] The flame length in the singeing step was 2.5 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com