Underground coal mine working face lower end plugging slurry blocking wall and process

A technology of working face and slurry wall, which is applied in mining equipment, filling materials, earth cube drilling and mining, etc., which can solve the threat to the life safety of on-site operators, poor water filtration effect of filling and sealing wall, and long construction time of sealing wall, etc. problems, to achieve the effect of preventing wall collapse, preventing roof sinking, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

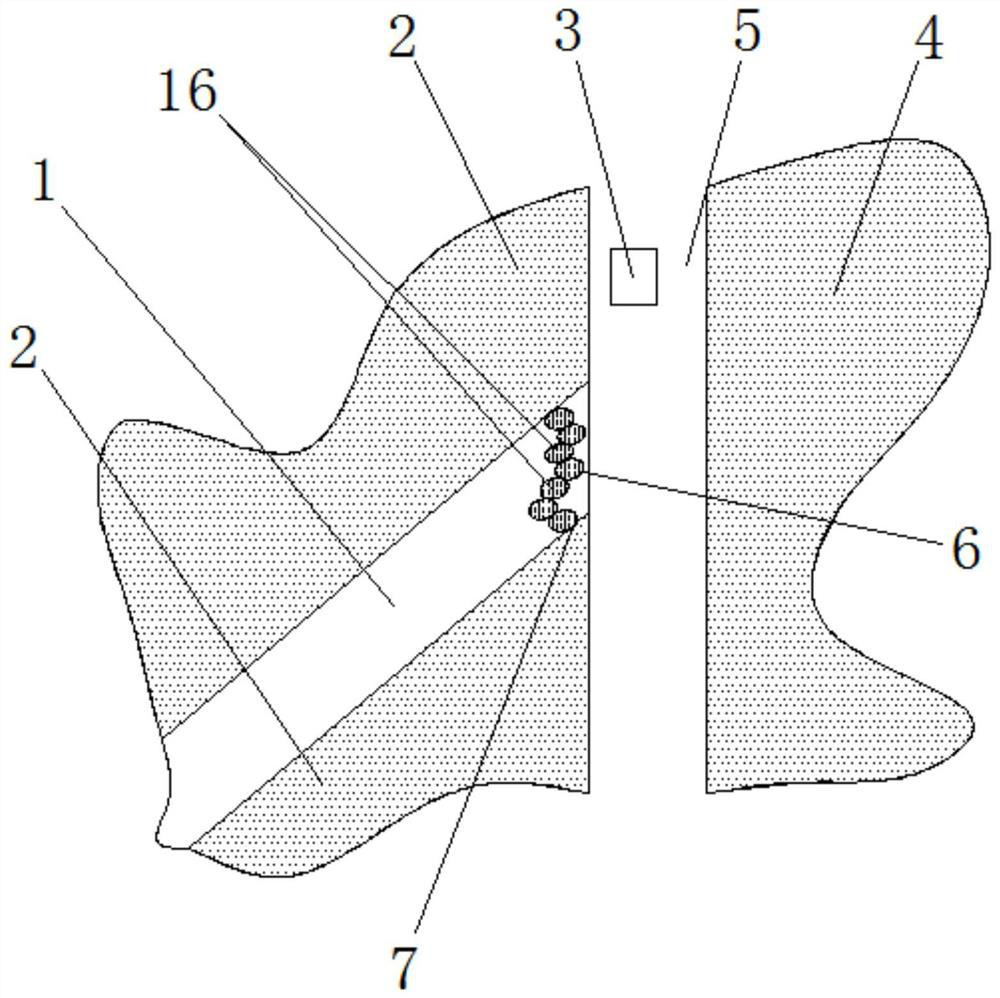

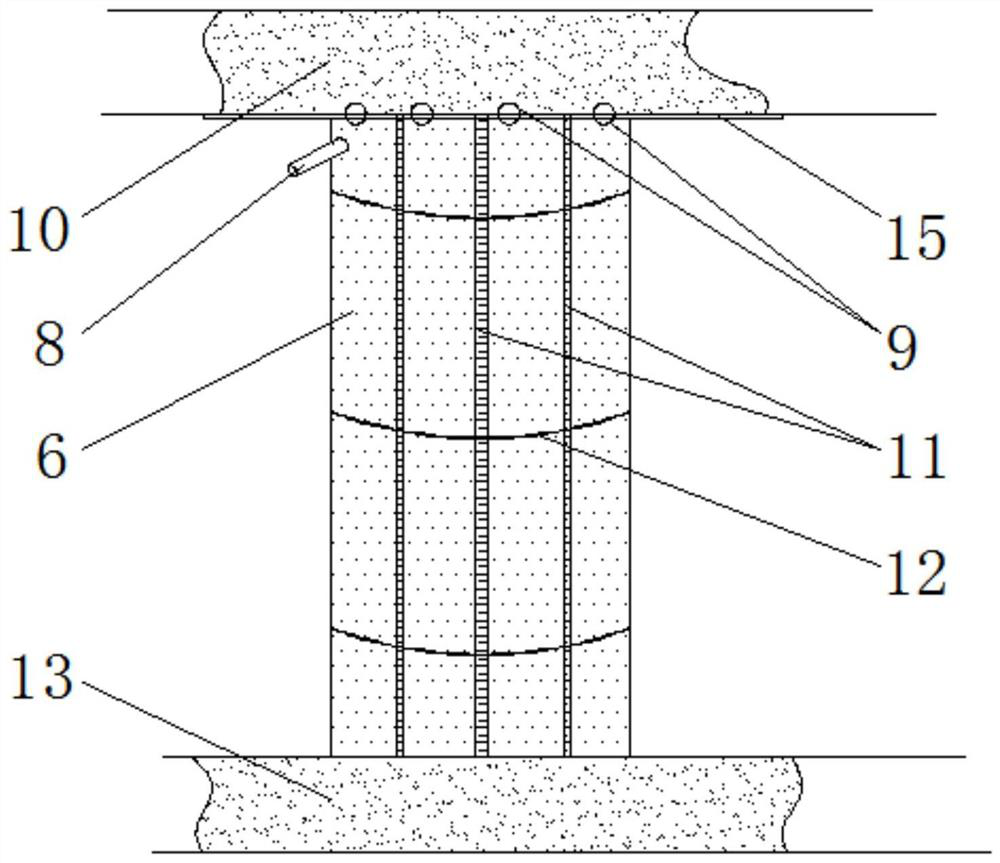

[0039] An underground coal mine working face lower end sealing slurry wall, such as figure 1 As shown, it is located at the end side of the filling branch roadway 1 connected to the transportation roadway 5 (that is, the lower end of the filling branch roadway 1). The filling branch roadway 1 is located in the middle of the first coal area 2, and the transportation roadway 5 is located between the first coal area 2 and the second coal area. Between the coal area 4, the top of the lower end of the filling branch roadway 1 is provided with a roof 10, and the bottom of the lower end of the filling branch roadway 1 is provided with a bottom plate 13; The flexible membrane piers 16 arranged side by side, such as figure 2As shown, the flexible film pier 16 includes a flexible film bag 6 vertically installed between the top plate 10 and the bottom plate 13 (the flexible film bag 6 is made of a material with strong tensile strength, good elongation performance, cold resistance and he...

Embodiment 2

[0053] In this embodiment, the difference between the lower end of the working face of the underground coal mine and the embodiment 1 is that:

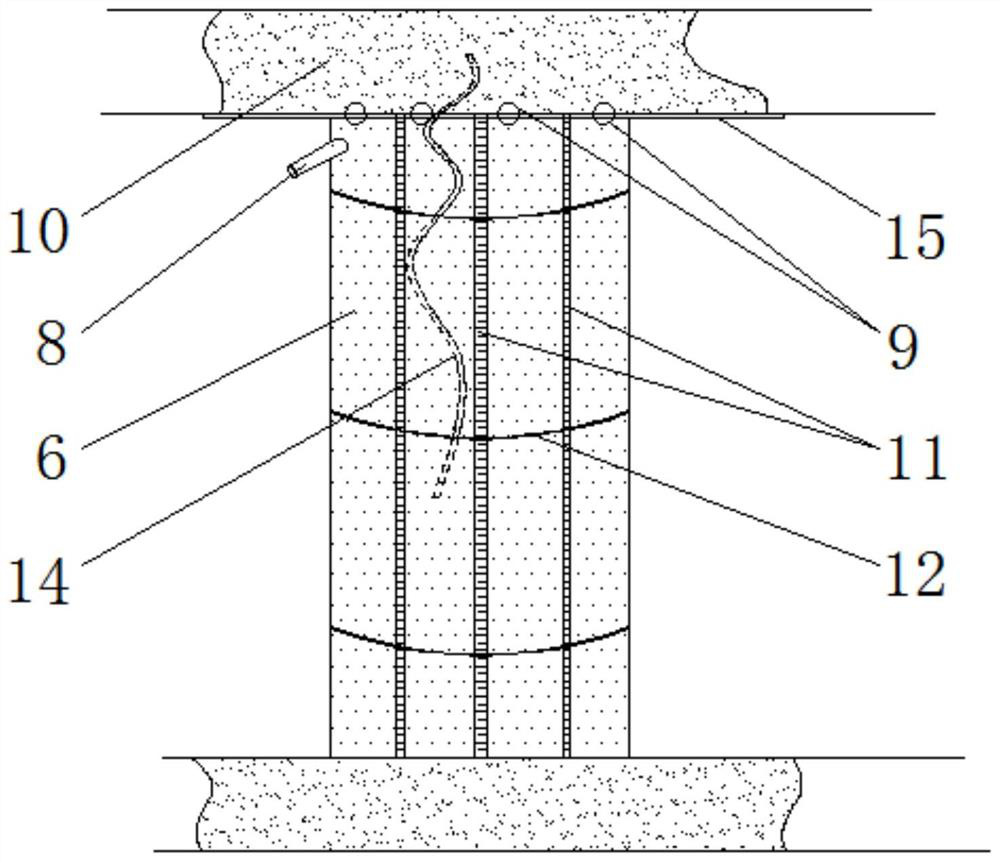

[0054] In this example, if image 3 As shown, each anchor 15 corresponding to the flexible film bag 6 is fixed with a chain 14 that hangs down into the flexible film bag 6 . After the chain 14 is installed, grouting is carried out again. After the filler is injected into the flexible membrane bag 6 and solidified and formed, a reinforced concrete structure is directly formed, which can improve the strength, stability and reliability of the flexible membrane pier 16.

[0055] In this embodiment, the filling materials include cement, sulphoaluminate, silicate and potassium salt, and their parts by mass are: 65 parts of cement, 17 parts of sulphoaluminate, 18 parts of silicate, potassium salt 8 servings.

[0056] Others are with embodiment 1.

[0057] The difference between the process of sealing the slurry wall at the lower end of th...

Embodiment 3

[0063] In this embodiment, the difference between the lower end of the working face of the underground coal mine and the embodiment 2 is that:

[0064] In this example, if Figure 4 As shown, the top plate 10 is fixed with a projection 17 extending downward to the inner side of the flexible film bag 6 , and the bottom of the projection 17 is lower than the grouting port 8 . After grouting, after the filling in the flexible film bag 6 is solidified and formed, the bumps 17 are buried in the filling, which can improve the connection stability between the filling and the top plate 10 .

[0065] In this embodiment, the filling materials include cement, sulphoaluminate, silicate and potassium salt, and their parts by mass are: 70 parts of cement, 20 parts of sulphoaluminate, 15 parts of silicate, potassium salt 5 servings.

[0066] Others are with embodiment 2.

[0067] The difference between the process of sealing the slurry wall at the lower end of the above-mentioned undergro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com