Magnetofluid sealing device capable of realizing multistage gas diversion

A magnetic fluid sealing and gas shunting technology, which is applied to the sealing of engines, pipe components, mechanical equipment, etc., can solve the problems of large limitations in gas path design and complex processing methods, and achieve convenient air pipe layout design and multi-stage design. The effect of gas splitting and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

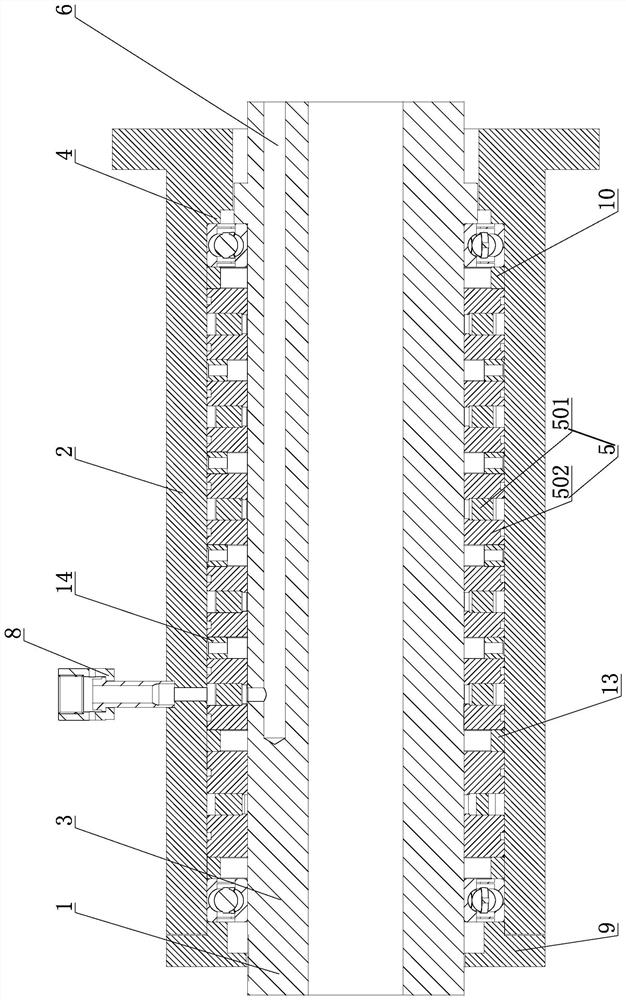

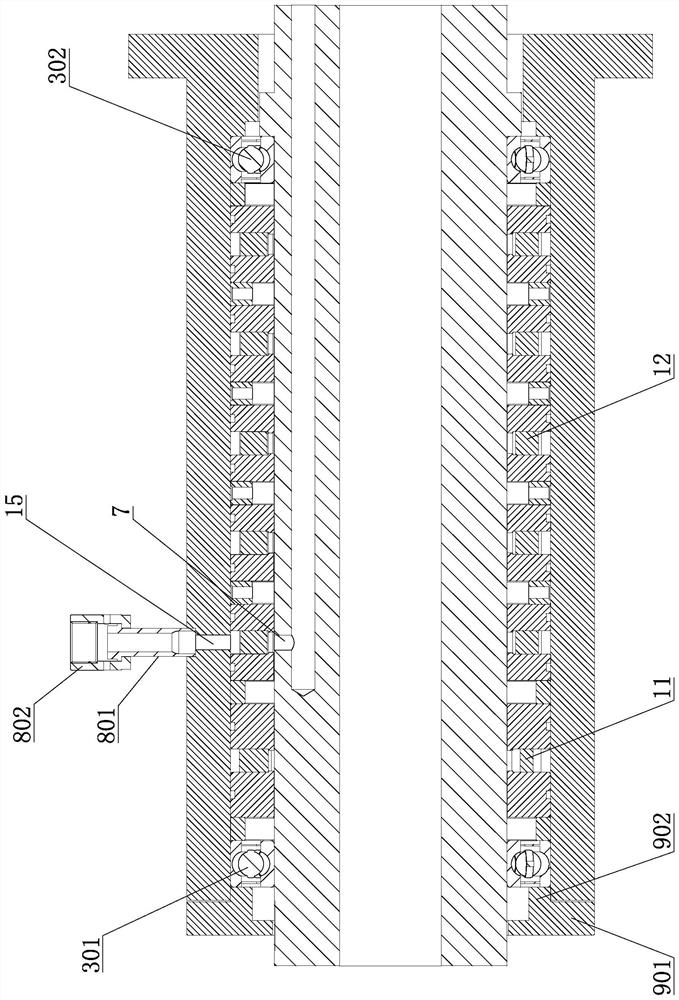

[0027] Such as figure 1 and figure 2As shown, a magnetic fluid sealing device capable of realizing multi-stage gas splitting includes a transmission shaft 1, a base 2 sleeved outside the transmission shaft, and bearings 3 and magnetic fluid are respectively arranged between the two ends of the base and the transmission shaft. The sealing assembly 5 is provided with a diversion hole 6 on the transmission shaft, and one end of the diversion hole communicates with the cavity, and an air hole 7 communicating with the diversion hole is provided on the peripheral surface of the transmission shaft. The first bearing 301 and the second bearing 302 on the side, the air hole is located between the first bearing and the second bearing, and the air supply assembly 8 is provided on the base; the magnetic fluid sealing assembly includes magnetic fluid, permanent magnet 501 and the permanent magnet The magnetic pole 502 on both sides, the magnetic fluid is arranged between the magnetic pol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap