Dual-mode detection system utilizing planar spiral coil capacitance effect

A capacitive effect, planar coil technology, applied in the direction of material capacitance, material resistance, material magnetic variable, etc., can solve the problems of non-conductive material detection, inability to penetrate deep metal defects, and achieve the best detection effect, increase line width effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific examples the present invention will be further described:

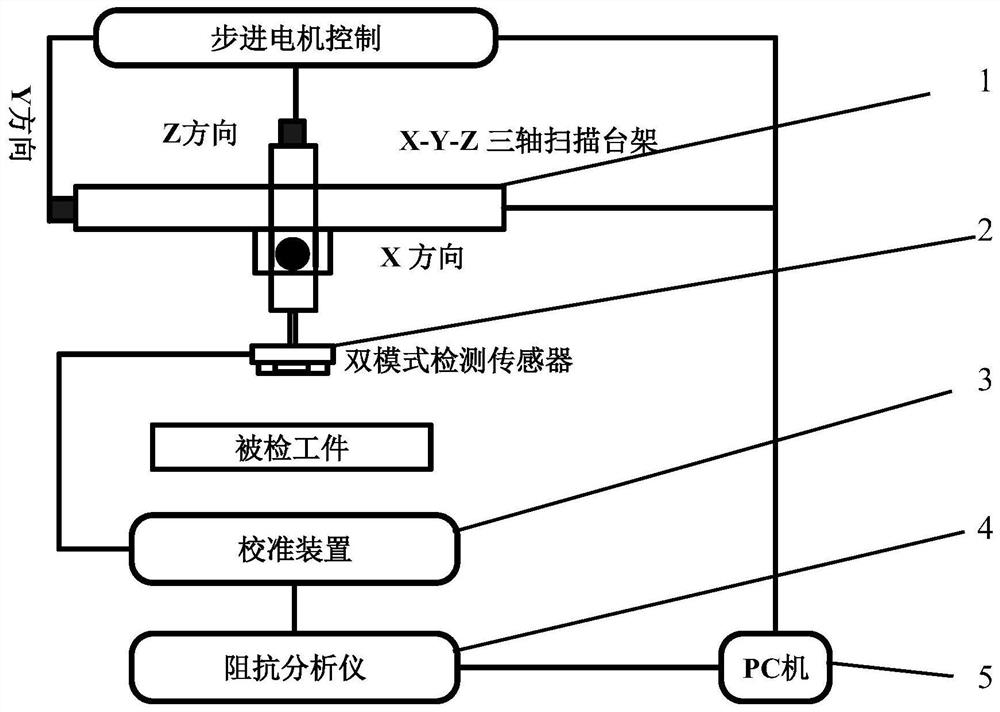

[0023] A dual-mode detection system utilizing the capacitive effect of a planar helical coil such as figure 1 with Figure 7 As shown, it includes an X-Y-Z three-axis scanning gantry 1, a dual-mode detection sensor 2, a calibration device 3, an impedance analyzer 4, and a PC 5;

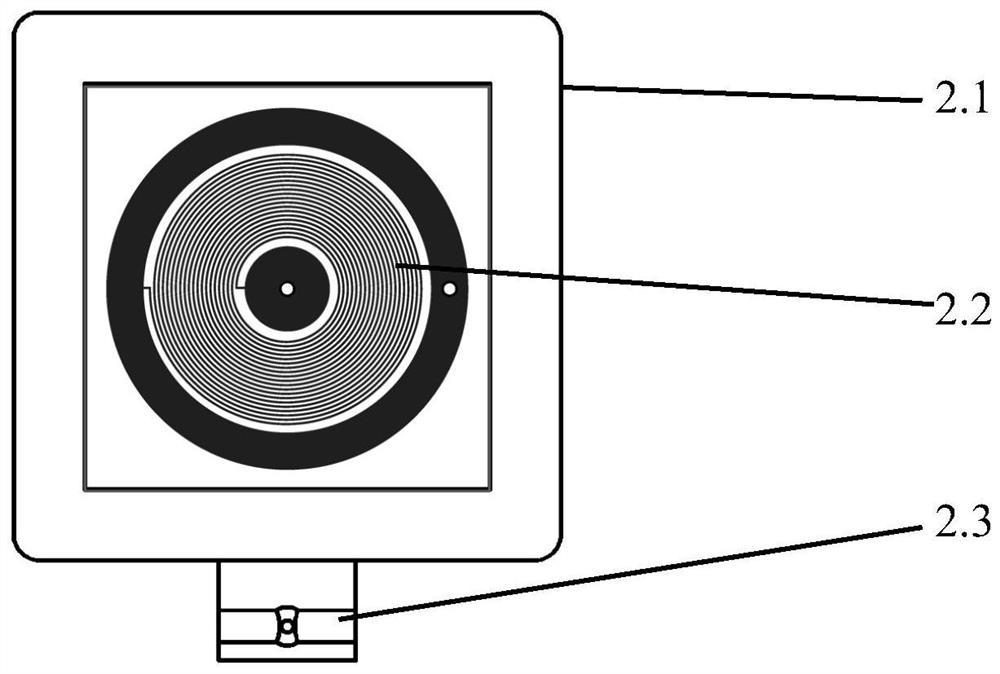

[0024] The dual mode detection sensor 2 such as figure 2 with 3 As shown, it includes a shell 2.1, a planar spiral coil 2.2 and a BNC interface 2.3.

[0025] The impedance analyzer 4 outputs a frequency-sweeping sinusoidal signal, which excites the dual-mode detection sensor 2 after passing through the calibration device 3. At this time, the dual-mode detection sensor 2 is still on the X-Y-Z three-axis scanning platform 1, and the impedance information changes with the frequency. Received by the impedance analyzer, the relevant frequency sweep data is recorded and analyze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com