Continuous casting billet surface pit defect identification method

A pit defect and identification method technology, applied in image data processing, instruments, calculations, etc., can solve problems such as increased risk factor, easy cracks, pits, increased loss of nickel-based steel, etc., to eliminate safety risks, data Comprehensive and specific, the effect of improving the safety index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

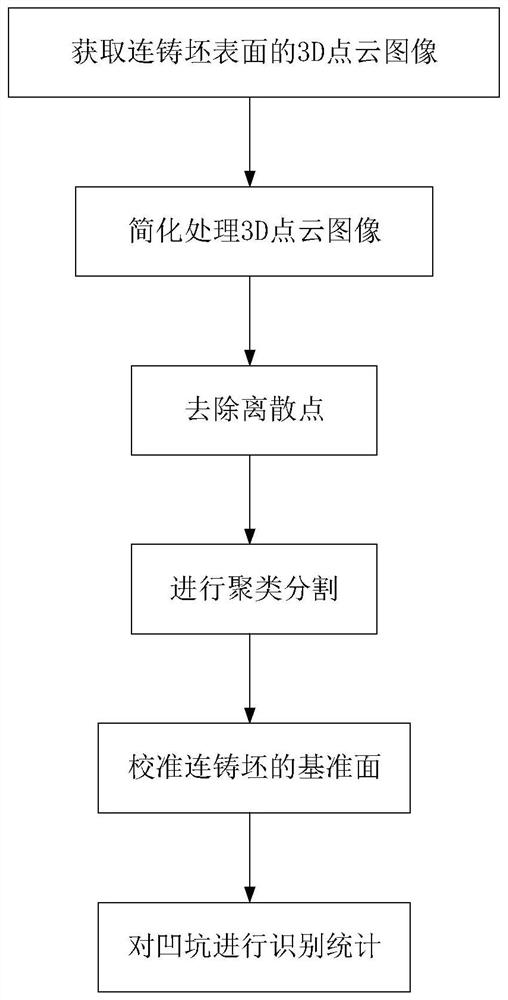

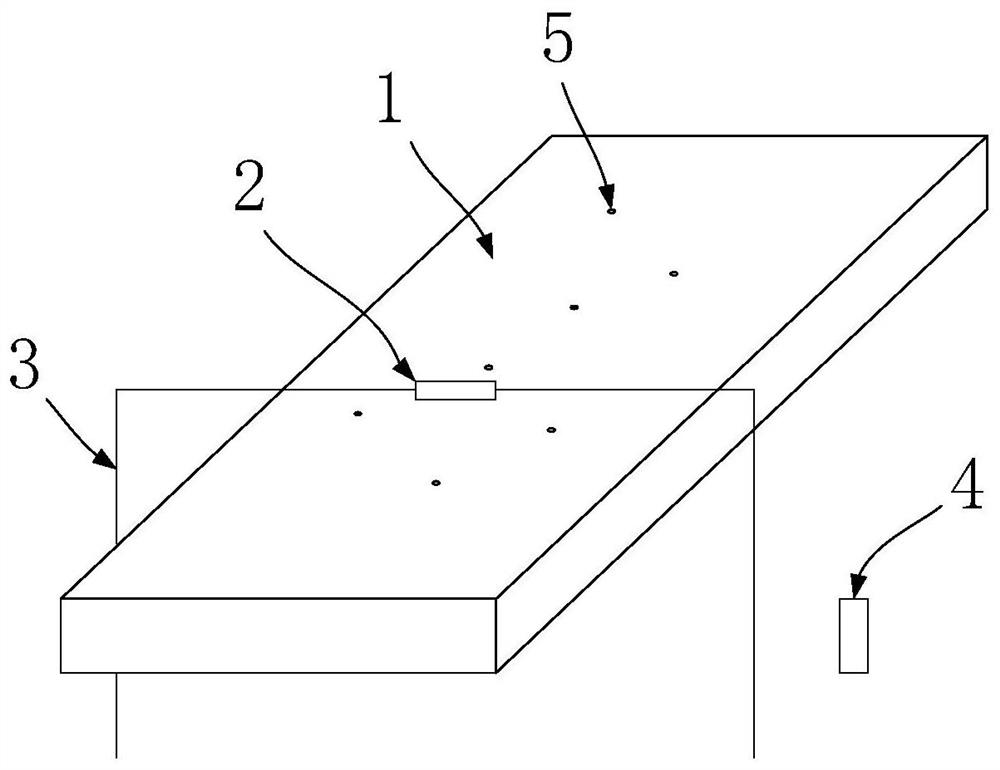

[0025] Such as figure 1 , 2 As shown, the 3D camera 2 is fixed above the ground roller table through the bracket 3 before the implementation of the pit defect identification method on the surface of the continuous casting slab, and the position, direction and angle of the visual inspection remain unchanged.

[0026] The identification steps include:

[0027] (1) Use the 3D camera 2 to photograph the surface of the continuous casting slab 1 after grinding, and obtain the 3D point cloud image of the continuous casting slab;

[0028] Specifically, when the grinding is completed, the continuous casting slab 1 advances to the visual detection position, and when the photoelectric sensor 4 detects the incoming signal of the continuous casting slab 1, the 3D camera 2 is triggered to take pictures, and the continuous casting slab point cloud image in PCD format is obtained.

[0029] (2) Use the downsampling algorithm to simplify the 3D point cloud image;

[0030] This function creat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com