Double-color COB packaging method

A packaging method and LED chip technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of poor control of the amount of two types of fluorescent glue, inconsistent light and color of products, etc., to achieve the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings of the description.

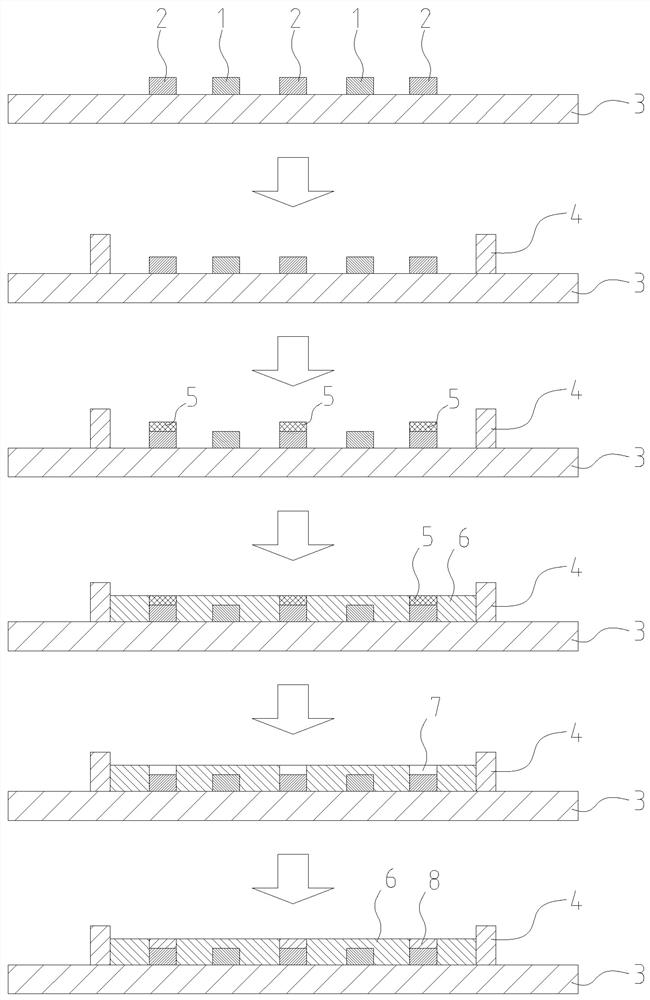

[0020] Such as figure 1 As shown, a packaging method of a two-color COB includes the following steps:

[0021] (1) Die-bonding on the die-bonding area of the substrate 3, the LED chip on the substrate 3 is divided into a first LED chip 1 and a second LED chip 2, and the first LED chip 1 and the second LED chip 2 are inverted The blue light chip installed, the LED chips are arranged in an array, the first LED chip 1 and the second LED chip 2 in the same row are arranged at intervals, and the first LED chip 1 and the second LED chip 2 in the adjacent row are arranged in a misplaced position. The setting can make the overall light output more uniform;

[0022] (2) Make a cofferdam 4 on the substrate 3 to surround the LED chip, and the height of the cofferdam 4 is higher than the height of the top surface of the LED chip;

[0023] (3) Dot glue on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com