Energy-saving and environment-friendly furnace kiln flue gas treatment device and treatment method thereof

A technology for flue gas treatment, energy saving and environmental protection, which is applied in combination devices, separation methods, chemical instruments and methods, etc., can solve the problems of corrosion of the inner wall of the purification tower and difficulty in cleaning the inner wall of the purification tower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

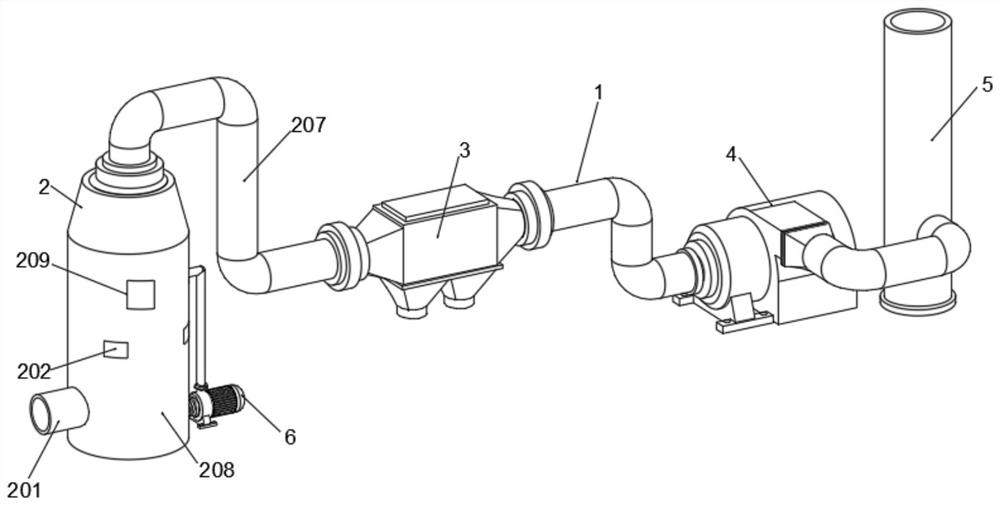

[0067] See Figure 1 - Figure 11 As shown, one of the objectives of the present embodiment is provided with an energy-saving environmental protection furnace kiln flux processing device, including the main body 1 and the purification tower 2 mounted on the main body 1, and at least in the purification tower 2 include:

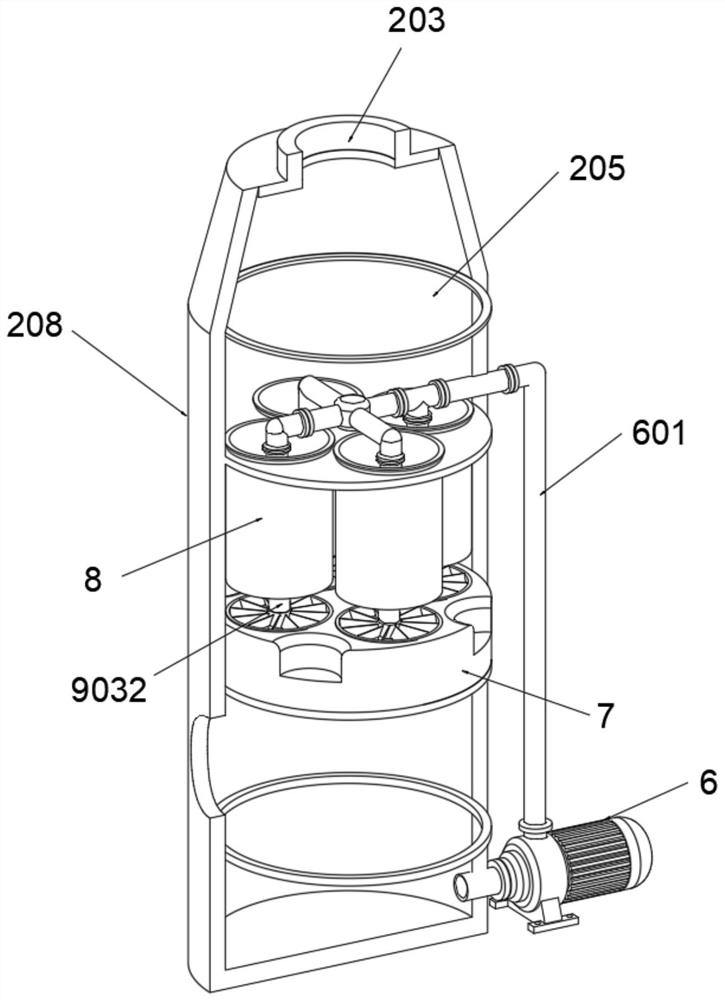

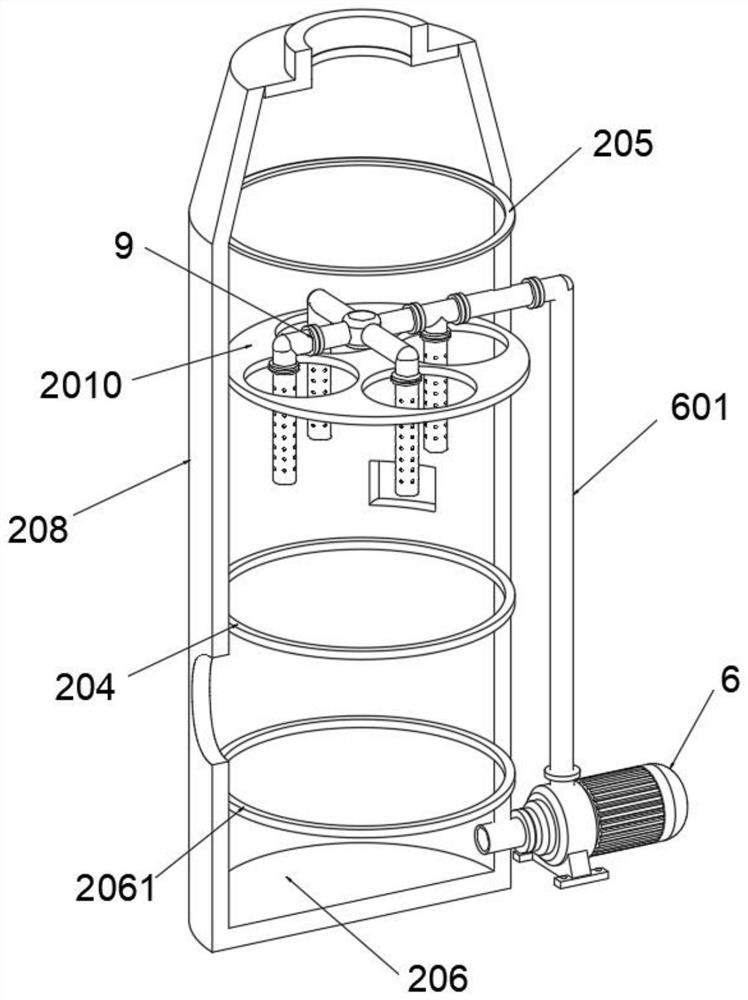

[0068] The housing 208, the side wall of the casing 208 is opened to the side of the bottom portion, and the outer wall of the housing 208 is provided with the cleaning window 202, and the cleaning window 202 is opened to be position corresponding to the storage recess 702. The deposit in the storage groove 702 is cleaned, and the top of the cleaning window 202 is provided with a maintenance window 209, further, the position filter element 801 provided by the repair window 209 corresponds to the filter element 801, and the repair window 209 size and the filter die 801 size The phase is adapted to facilitate the maintenance of the filter element 801 and the first spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com