A method for preparing micro-nano gel microspheres based on metastable emulsion

A technology of gel microspheres and metastable states, applied in the field of bioengineering, can solve the problems of high cost, cumbersome production process, poor water solubility, etc., and achieve the effect of simplifying production steps and avoiding complicated process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

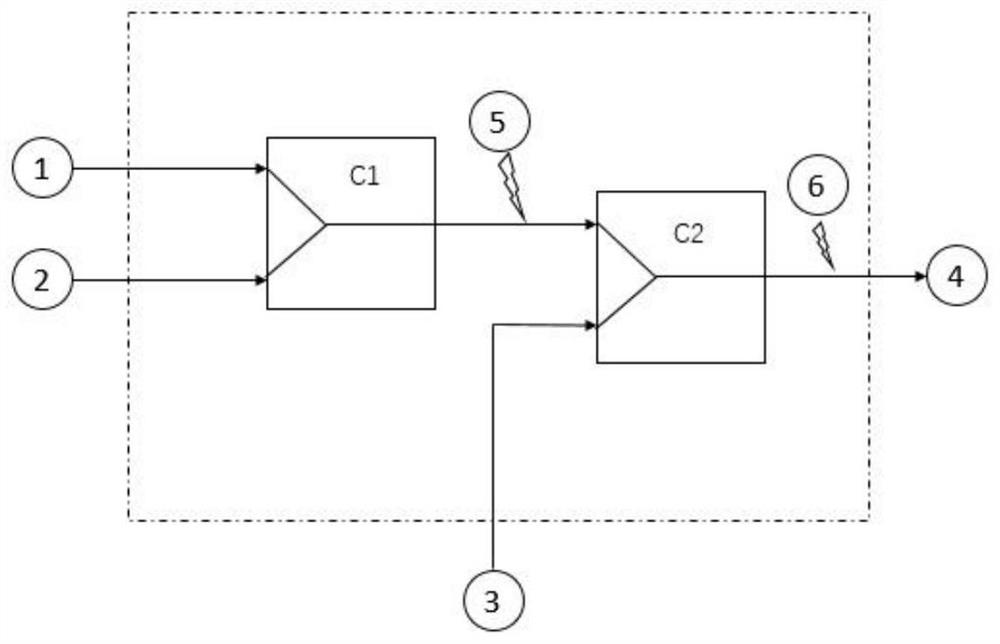

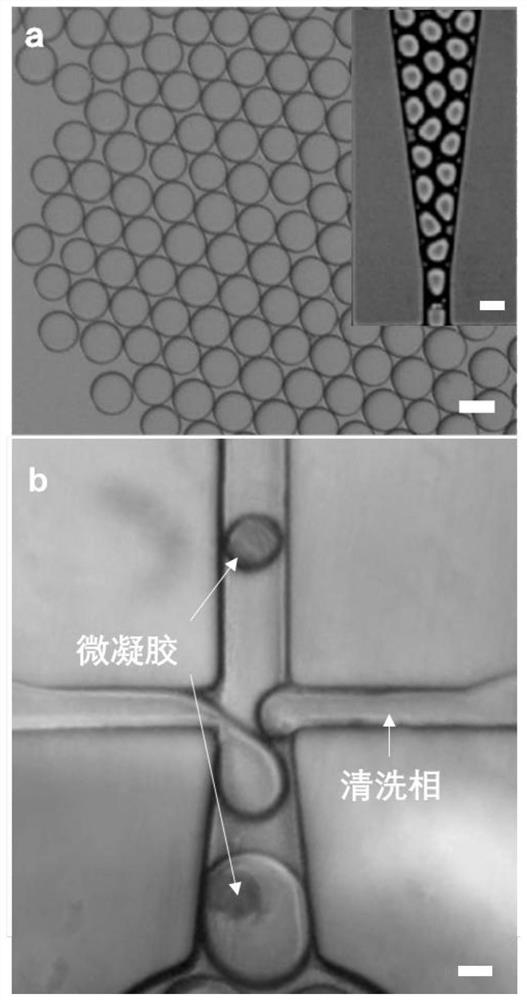

[0074] like figure 1 Shown, a small amount of fluorinated surfactant listed in the present invention adds and can significantly reduce interfacial tension between water and oil, use as figure 2 Microgel prepared by the microchannel shown, in which ① connect to the first input channel, input the alginic acid prepolymer solution, ② connect to the second input channel, input the oil phase containing acid and surfactant, ③ connect to the third input channel , input pure water or buffer solution; ④ connect the output channel. The surface of the inner wall of the microchannel is all subjected to hydrophobic treatment.

[0075] Dissolve sodium alginate and calcium ethylenediaminetetraacetic acid (Ca-EDTA) in deionized water to prepare an alginic acid hydrogel prepolymer solution with a sodium alginate content of 1w / v% and a final calcium ion concentration of 50mM as The water phase enters the water phase channel from the first input channel. Add 1H, 1H, 2H, 2H-perfluoro-1-octanol...

Embodiment 2

[0085] use as figure 2 The micro-channels shown are used to prepare microgels, in which ① connect to the first input channel, input alginic acid prepolymer solution, ② connect to the second input channel, input the oil phase containing acid and surfactant, ③ connect to the third input channel , input pure water or buffer solution; ④ connect the output channel. The surface of the inner wall of the microchannel is all subjected to hydrophobic treatment.

[0086] Dissolve sodium alginate and calcium ethylenediaminetetraacetic acid (Ca-EDTA) in deionized water to prepare an alginic acid hydrogel prepolymer with a sodium alginate content of 1w / v% and a final calcium ion concentration of 50mM; above Configure the prepolymer solution as the water phase to enter the water phase channel from the first input channel. Add 1H, 1H, 2H, 2H-perfluoro-1-octanol and acetic acid into Novec HFE7100 and enter the second input channel as the oil phase and enter the oil phase channel ②. The con...

Embodiment 3

[0088] use as figure 2 The micro-channels shown are used to prepare microgels, in which ① connect to the first input channel, input alginic acid prepolymer solution, ② connect to the second input channel, input the oil phase containing acid and surfactant, ③ connect to the third input channel , input pure water or buffer solution; ④ connect the output channel. The surface of the inner wall of the microchannel is all subjected to hydrophobic treatment.

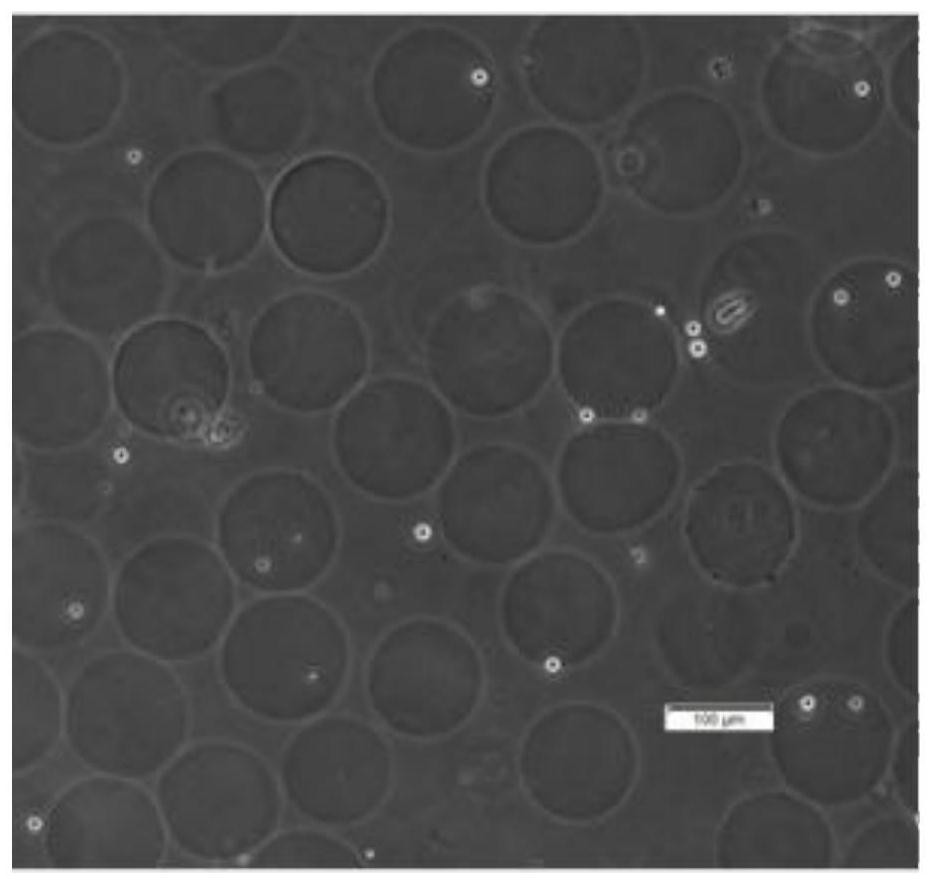

[0089] In order to prove that amphoteric fluoride molecules with different chain lengths have the ability to produce microgel particles, sodium alginate and calcium ethylenediaminetetraacetic acid (Ca-EDTA) were dissolved in deionized water to prepare a sodium alginate content of 1w / v% , the alginic acid hydrogel prepolymer with a final calcium ion concentration of 50 mM; the prepolymer solution configured above as the water phase enters the water phase channel from the first input channel. After adding different kinds of fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com