Crane running track cleaning device for production workshop

A technology for cleaning devices and production workshops, which can be applied to cleaning methods using tools, cleaning methods using liquids, cleaning methods and utensils, etc., and can solve problems such as pollution, delaying the normal production of the workshop, and hindering the normal operation of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

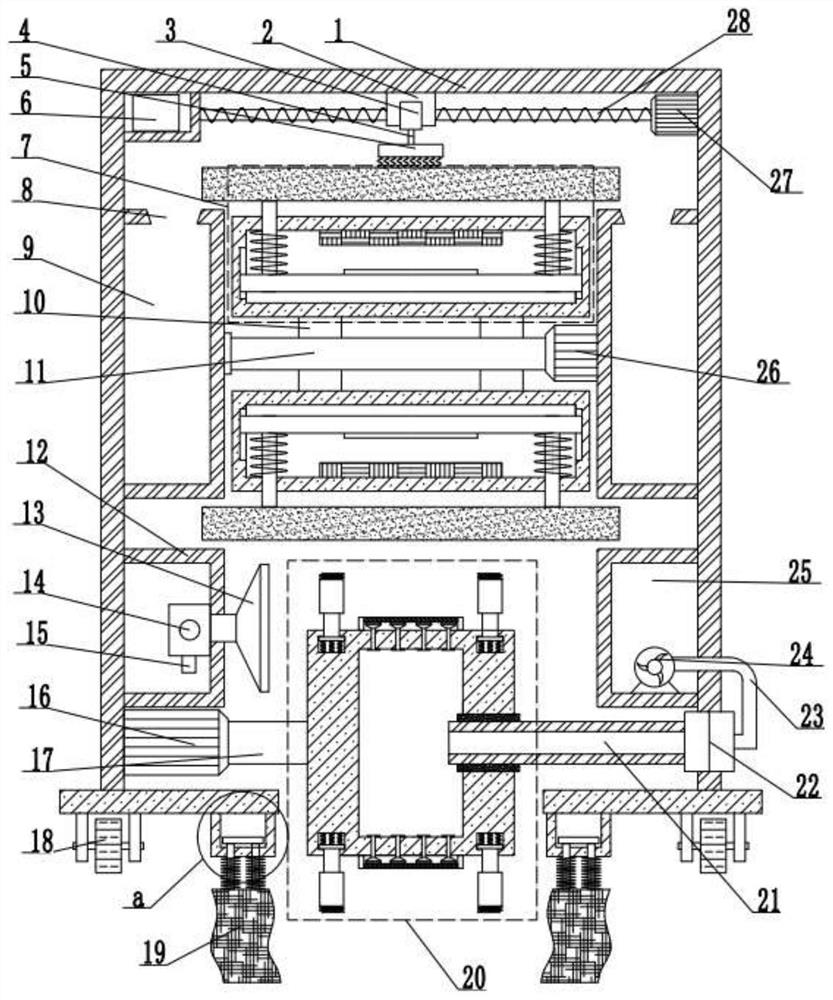

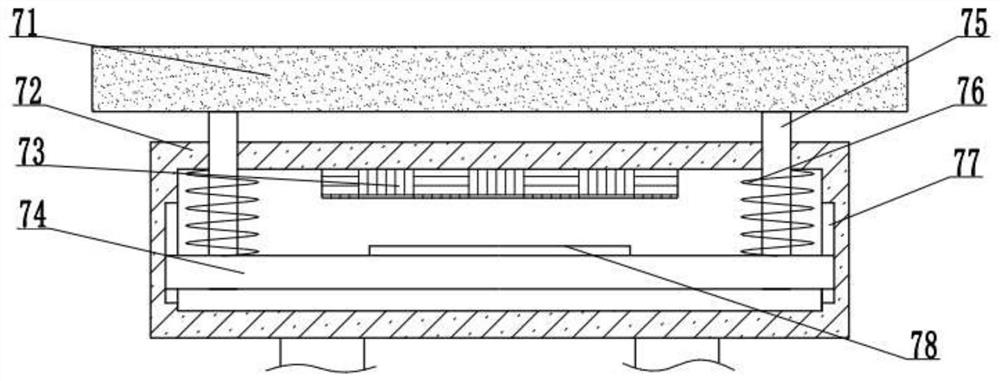

[0028] see Figure 1 to Figure 5 , a crane track cleaning device for a production workshop, comprising a housing 1, a cleaning device 20, an adsorption device 7, a first cleaning brush 5 and a recovery box 9, the cleaning device 20 is located below the housing 1, and passes through a solid The shaft 17 is connected to the first servo motor 16. The cleaning device 20 includes a fixed plate 201 and a second cleaning brush set 203. The second cleaning brush set 203 is embedded in a square groove on the surface of the fixed plate 201 through a fixed rod 204. And the bottom of the fixed rod 204 is connected to the inner wall of the square groove by the second damping spring 205, the second damping spring 205 can weaken the second cleaning brush 203 from the longitudinal force from the ground, prevent it from being damaged, and prolong the service life. The number of two cleaning brushes 203 is several, and they are symmetrical about the center of the fixed disk 201. The first servo...

Embodiment 2

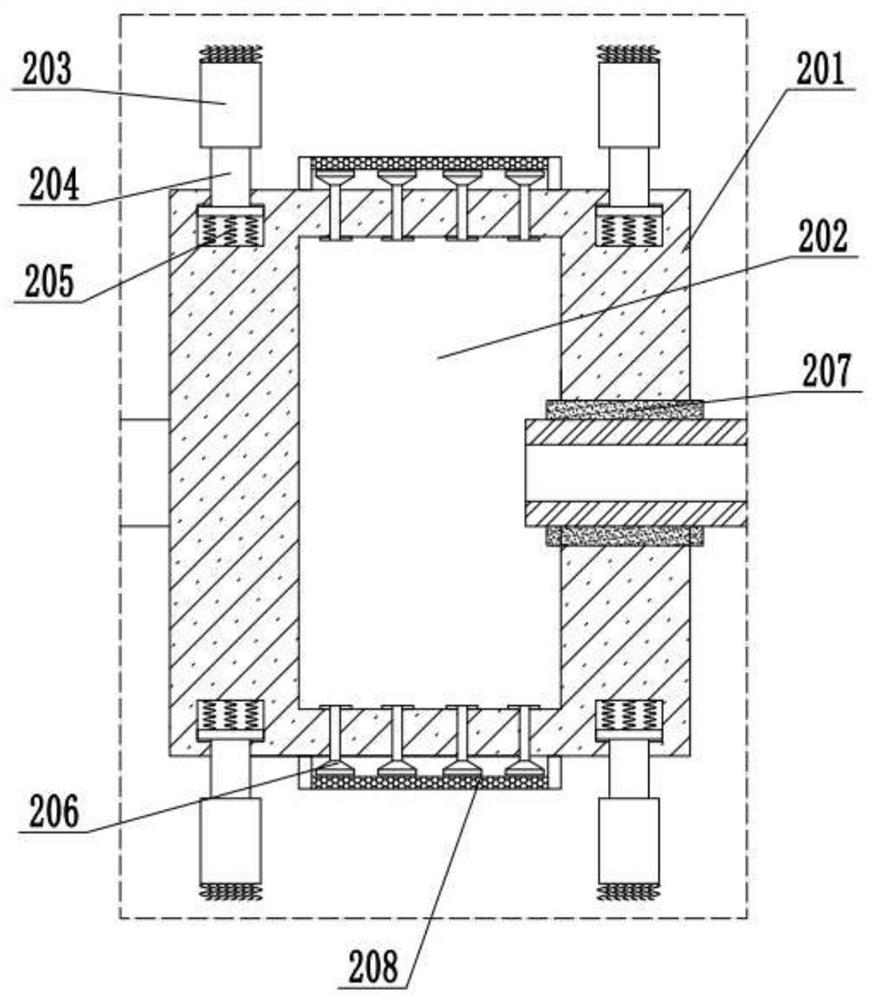

[0034] see figure 1 and image 3 , a crane running track cleaning device for a production workshop, which also includes a fixed plate 201, and a sealed cavity 202 is provided inside the fixed plate 201, and a plurality of high-pressure water spray valves 206 are fixedly connected to the surface of the sealed cavity 202. The side wall of the sealing chamber 20 is fixedly connected with a hollow shaft 21, and the outer side of the hollow shaft 2 is sleeved with a sealing ring 207 to prevent leakage and has the characteristics of good sealing performance. The hollow shaft 21 is connected to the water guide pipe 23 through the connecting plate 22, The water guide pipe 23 is fixedly connected to the water pump 24 in the water tank 25, and the outside of the high-pressure water spray valve 206 is also sleeved with a filter screen 208, which can prevent dust and metal residues from blocking the high-pressure water spray valve 206 and play a protective role. The service life of the w...

Embodiment 3

[0036] see figure 1 , a crane track cleaning device for a production workshop, which also includes a cleaning device 20, and a dust collection valve 13 is arranged on one side of the cleaning device 20, and the dust collection valve 13 is connected to the inner wall of the dust removal box 12 through a dust suction pipe. The air pump 14, the dust discharge pipe 15 is fixedly connected under the air pump 14, the dust collection valve 13 can absorb the dust generated during the cleaning process, and absorb it into the dust removal box 12 for centralized treatment, which has the characteristics of environmental protection .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com