Kitchen waste treatment method

A treatment method and a technology of food waste, applied in the direction of combustion method, microbial treatment, combined biological treatment, etc., can solve the problems of difficult site selection, long treatment cycle, and low utilization rate of resources, so as to improve treatment efficiency and utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

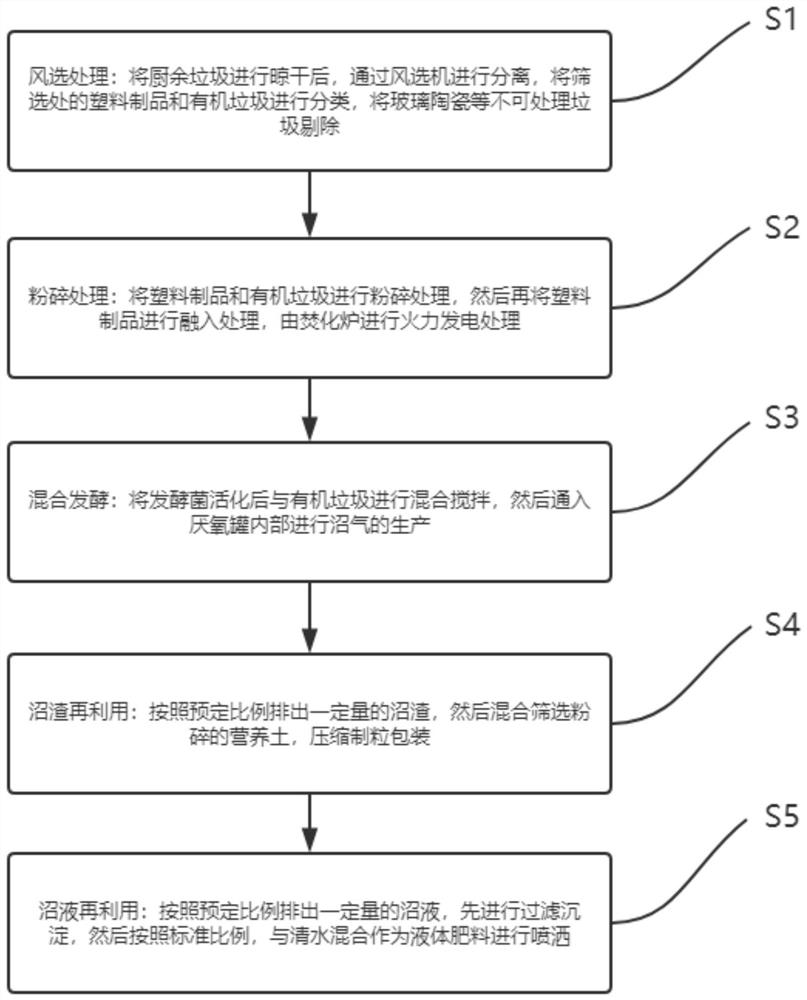

[0022] see figure 1 , the present invention provides a technical solution: a method for treating kitchen waste, comprising the following steps:

[0023] Step 1. Air separation treatment: After the kitchen waste is dried, it is separated by an air separation machine, and the plastic products and organic waste in the screening place are classified, and glass ceramics and other non-disposable wastes are removed.

[0024] Step 2. Crushing treatment: the organic waste is pulverized, and then the plastic products are subjected to hot-melt treatment, followed by granulation, and finally treated by thermal power generation in an incinerator.

[0025] Step 3. Mixed fermentation: After the fermentation bacteria are activated, they are mixed and stirred with organic waste, and then passed into the anaerobic tank for biogas production.

[0026] Step 4. Biogas residue reuse: Discharge a certain amount of biogas residue according to a predetermined ratio, then mix and screen the crushed nu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap