Automatic boxing mechanism for box packaging and working method of automatic boxing mechanism

An automatic packing and sealing machine technology, which is applied in the directions of automatic packaging control, packaging, transportation and packaging, etc., can solve the problems of uncoordinated coding operation of packaging boxes, reducing the efficiency and quality of production lines, and incomprehensible packaging operations. To achieve the effect of reducing personnel workload, improving packing efficiency, and eliminating omissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

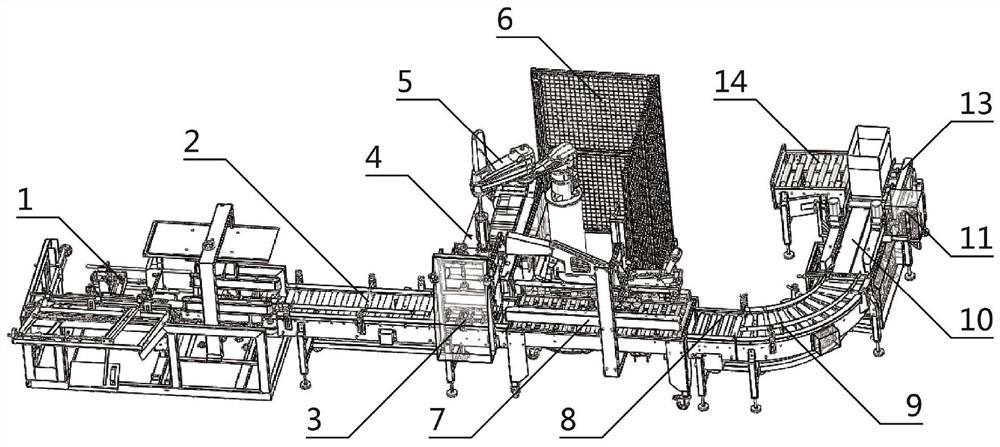

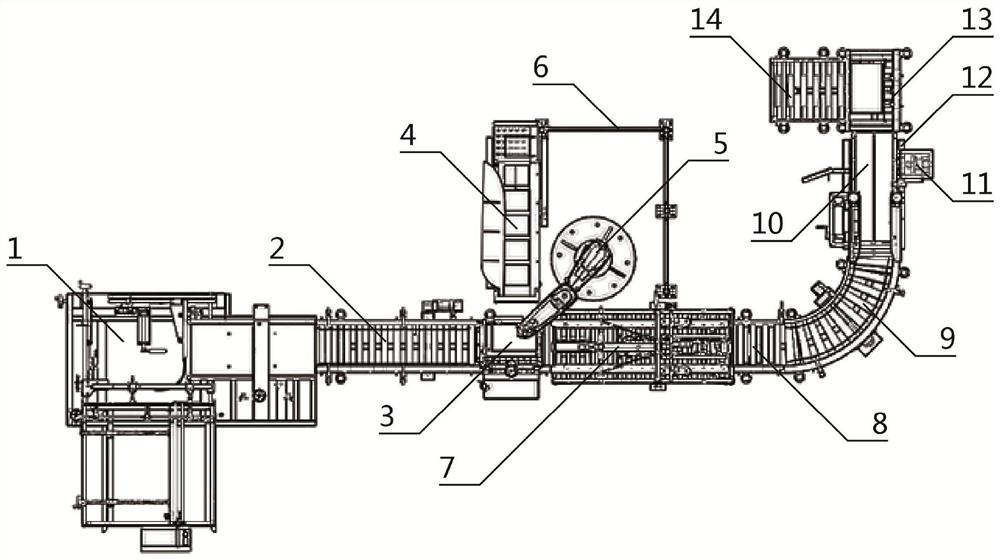

[0028] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0029] Such as figure 1 , figure 2Shown is an automatic box packing mechanism for box packaging and its working method, which is characterized in that: a box unpacking machine 1, a first conveying line body 2, a box packing fixing device 3, an article pushing device 4, and a mechanical arm 5 , guardrail 6, box sealing machine 7, weighing device 8, second conveying line body 9, stagnant conveying device 10, code spraying device 11, code reading device 12, box body pushing device 13 and third conveying line body 14, The unpacking machine 1, the first conveying line body 2, the packing fixing device 3, the article pushing device 4, the mechanical arm 5, the guardrail 6, the case sealing machine 7, the weighing device 8, the second conveying line body 9, stagnation The conveying device 10, the code spraying device 11, the code read...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com