Intelligent loop line conveying line equipment

A conveyor line and equipment technology, applied in the field of conveyor lines, can solve the problems of high equipment cost, achieve the effects of reducing equipment cost, facilitating promotion, and reducing transportation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

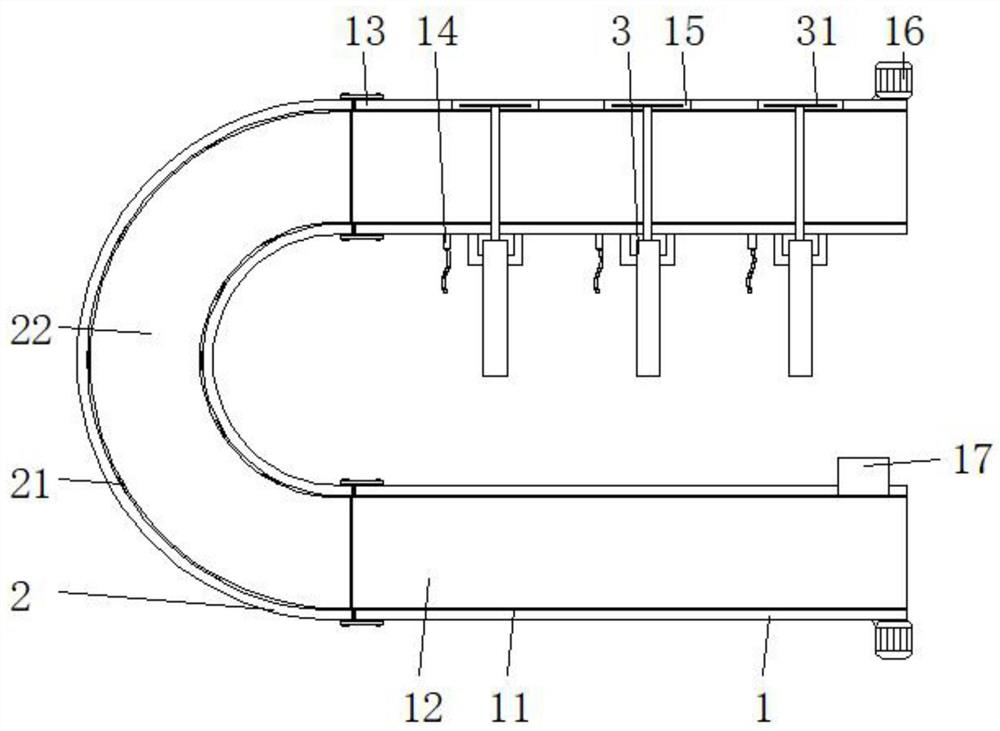

[0028] Embodiment 1: including the first conveying device body 1, the third conveying device body 2 and the support plate 4, the outer wall of the first conveying device body 1 is provided with a second conveying device body 13, the first conveying device body 1 and the second conveying device body The outer wall of one side of the conveying device body 13 is provided with a third conveying device body 2, and one side of the inner wall of the third conveying device body 2 is rotatably mounted with a circular array of turning rollers 21, and the outer wall of one side of the turning roller 21 is sleeved with a second conveying device body. Belt 22, turning roller 21 achieves the purpose of changing the moving direction of goods through the second conveyor belt 22;

[0029] The outer wall of one side of the third delivery device body 2 is equipped with connecting rods 23 distributed in a rectangular array, and the outer wall of one side of the connecting rods 23 is rotatably equi...

Embodiment 2

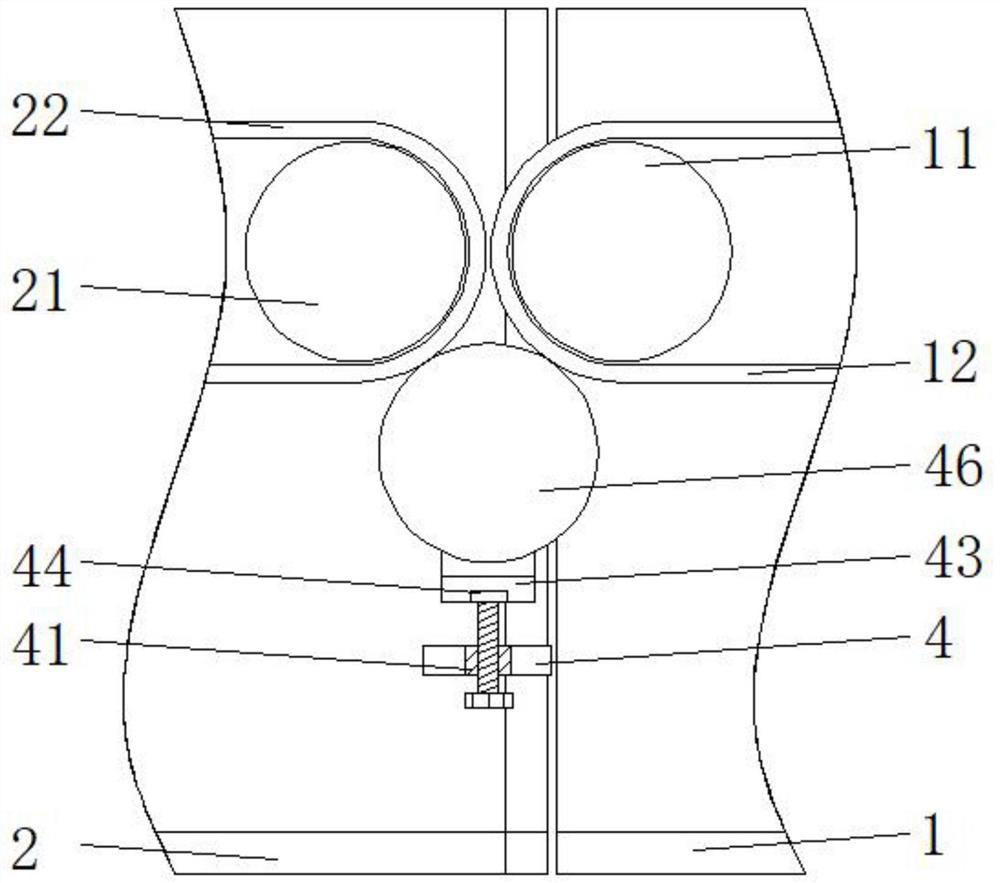

[0032]Embodiment 2: including the first conveying device body 1, the third conveying device body 2 and the support plate 4, the outer wall of the first conveying device body 1 is provided with a second conveying device body 13, the first conveying device body 1 and the second conveying device body The outer wall of one side of the delivery device body 13 is provided with the third delivery device body 2, and the outer walls of the first delivery device body 1 and the second delivery device body 13 are symmetrically installed with limit rods 18, and the lower end of the third delivery device body 2 inner wall is The support plate 4 is installed symmetrically on the side, and the inside of the support plate 4 is provided with a screw hole 41, and the screw hole 41 is internally threaded to be connected with a screw rod 42, and a first bearing 44 is installed on one side of the outer wall of the upper end of the screw rod 42, and the first conveying device body 1 and the second On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com