Humidity-adjusting ceramic tile with decorative effect and preparation method thereof

A decorative effect and ceramic tile technology, which is applied to clay products, household utensils, and other household utensils, and can solve problems such as low strength and single surface decoration of humidity-adjusting bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

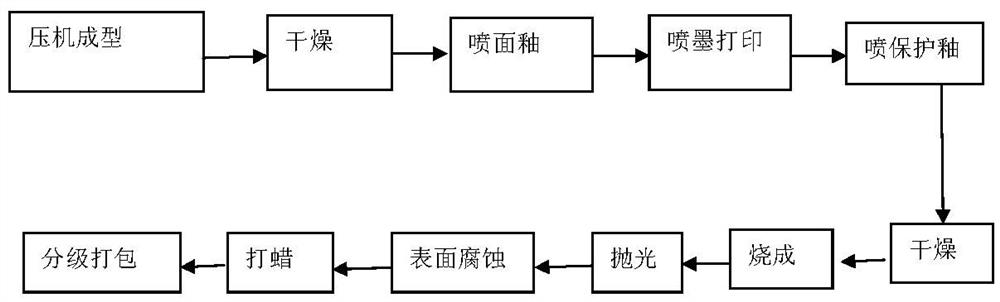

[0046] 1. The green body is pressed into a powder press to obtain a green body. Dry the body.

[0047] 2. Spray the surface glaze on the surface of the dried body. The chemical composition of the enamel includes: in mass percent, SiO 2 : 61.9-64.15%, Al 2 O 3 : 19.78-22.08%, Fe 2 O 3 : 0.22-0.4%, TiO 2 : 0.15-0.25%, CaO: 0.2-0.4%, MgO: 0.1-0.2%, K 2 O: 3-4%, Na 2 O: 3.15-3.77%, ZrO 2 : 3.2-9.6%, loss on ignition: 1.5-2%. The specific gravity of the glaze is 1.3-1.5g / cm 3 , the amount of glazing 500-600g / m 2 .

[0048] 3. Inkjet print the design pattern on the surface of the body after spraying the glaze.

[0049] 4. Spray protective glaze on the surface of the green body after inkjet printing the design pattern. The chemical composition of the protective glaze includes: in mass percent, in mass percent, SiO 2 : 45-50%, Al 2 O 3 : 18-22%, Fe 2 O 3 : 0.08-0.15%, TiO 2 : 0.1-0.2%, CaO: 0.1-0.3%, MgO: 4-6%, BaO: 10-13%, ZnO: 2-4%, K 2 O: 4-5%, Na 2 O: 1-2%, l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com