Polypropylene yarn production equipment

A polypropylene and yarn technology, which is applied in the field of polypropylene yarn production equipment, can solve problems such as fiber breakage, uneven running speed, easy breakage and damage, and achieve the effect of reducing tension and avoiding being torn off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

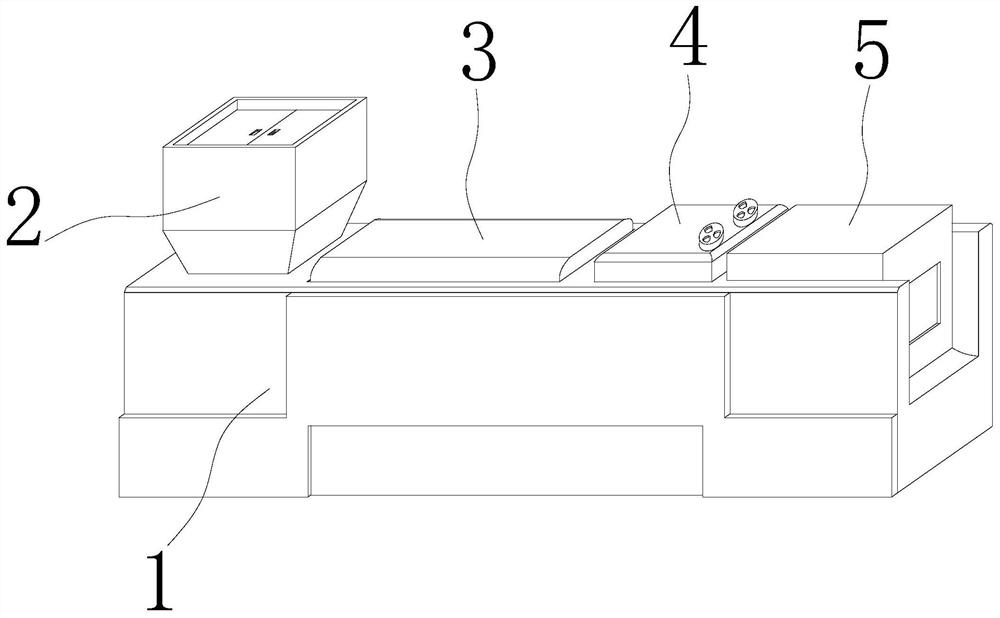

[0026] Such as Figure 1-Figure 5 As shown, the present invention provides a kind of production polypropylene yarn equipment, and its structure comprises machine body 1, feeder 2, extruder 3, spinning device 4, winding device 5, and described feeder 2 bottom periphery Embedded and connected to the inside of the top left side of the body 1, the center of the left side of the extruder 3 is driven to fit inside the body 1, and the peripheral bolts at the bottom end of the thread extractor 4 are connected to the right side of the bottom end of the body 1. The left side wall of the winding device 5 is fitted and connected to the periphery of the protrusion on the right side wall of the thread extractor 4 .

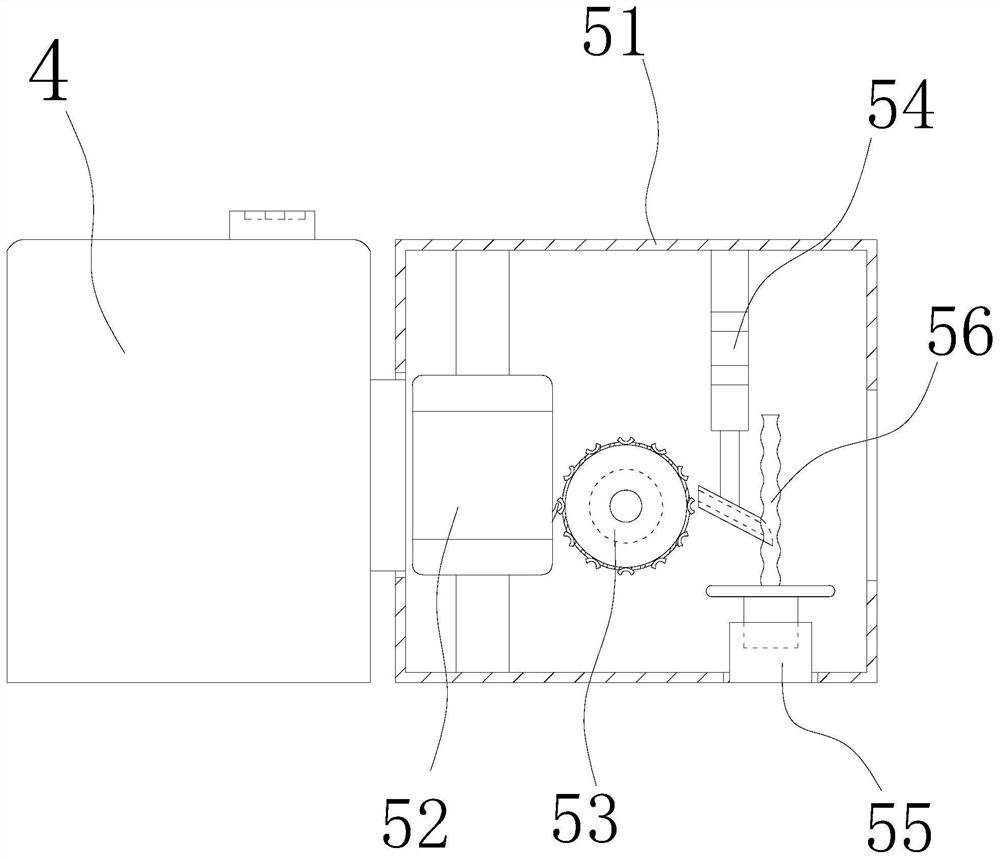

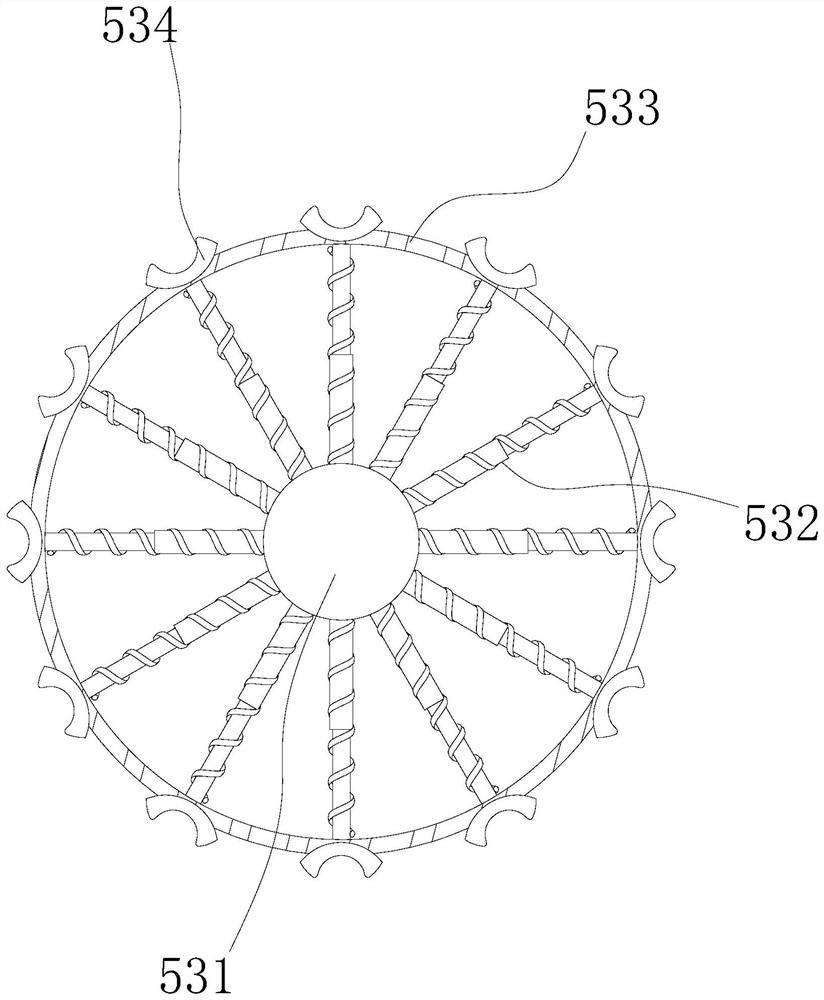

[0027] The winding device 5 includes a casing 51, a thread twister 52, a transmission device 53, an engaging block 54, a driver 55, and a winding shaft 56. The bottom end of the thread twister 52 is embedded and connected to the left side of the bottom end of the inner wall of ...

Embodiment 2

[0034] Such as Figure 6-Figure 7 Shown:

[0035] Wherein, the clamping shaft a3 includes a shaft body a31, a shaft housing a32, and a clamping mechanism a33, the inner center of the shaft housing a32 is movably matched with the periphery of the end of the shaft body a31, and the clamping block a33 is movably engaged with the shaft housing a32 inner wall, the shaft a31 is a highly lubricated bearing, the use of this kind of bearing can reduce the friction during the winding process of silk.

[0036] Wherein, the clamping mechanism a33 includes a connecting piece c1, a concave block c2, a receiving piece c3, and a protruding piece c4. Connected to the inner wall of the top end of the depression of the concave block c2, the bottom end of the convex block c4 is embedded and connected to the center of the top end of the concave block c2, and the receiving piece c3 is a highly deformable elastic sheet structure, which makes the thread When it is located on the upper surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com