Ecological removing structure of reinforced concrete inner support and construction method thereof

A technology of reinforced concrete and concrete columns, which is applied in building construction, earth mover/excavator, building maintenance, etc., and can solve problems such as difficult operation, difficult implementation, and the impact of surrounding residents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

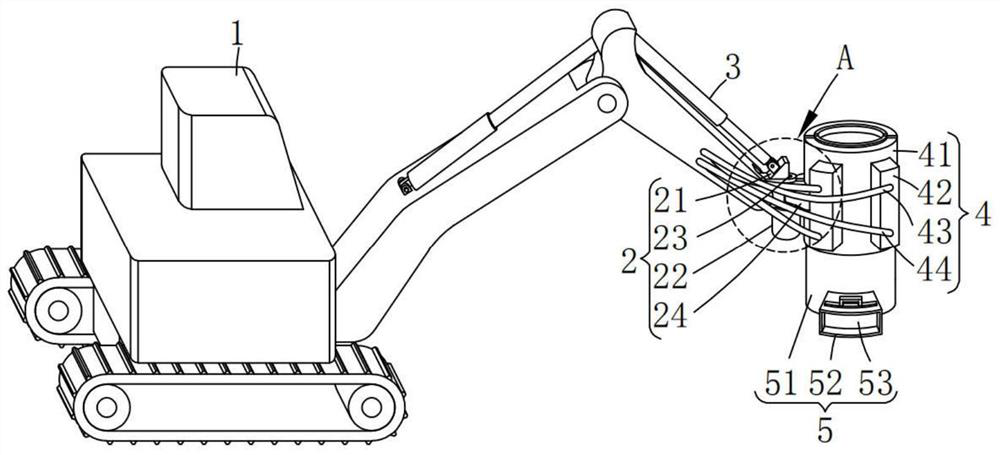

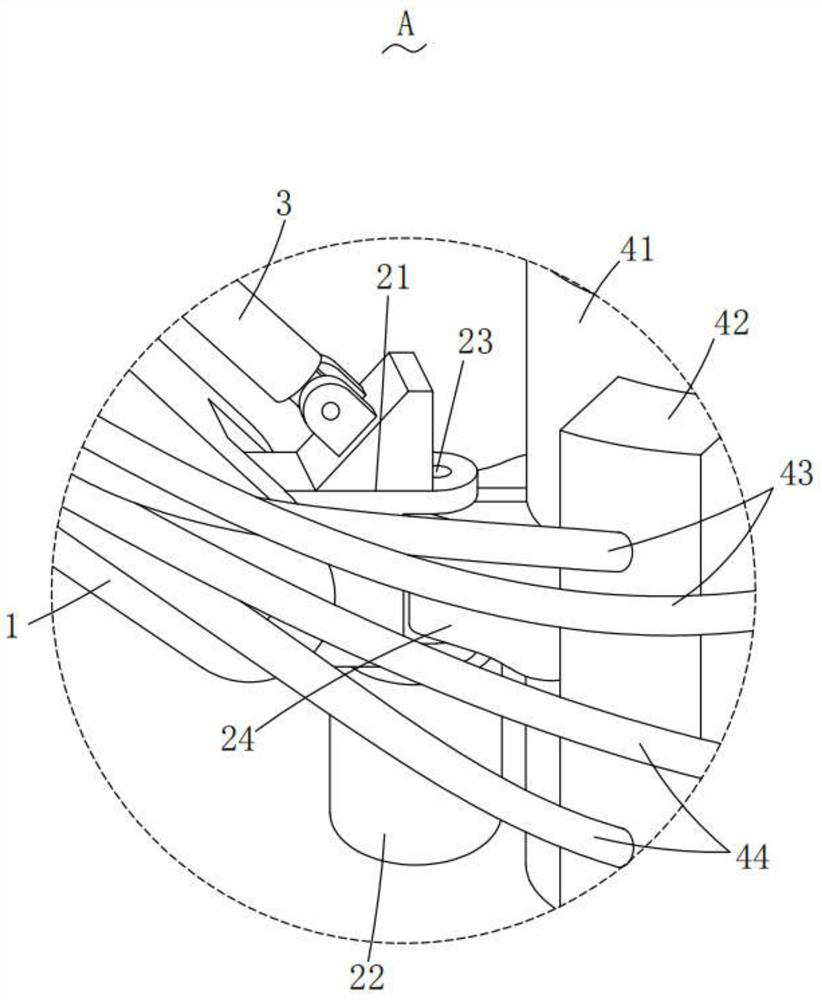

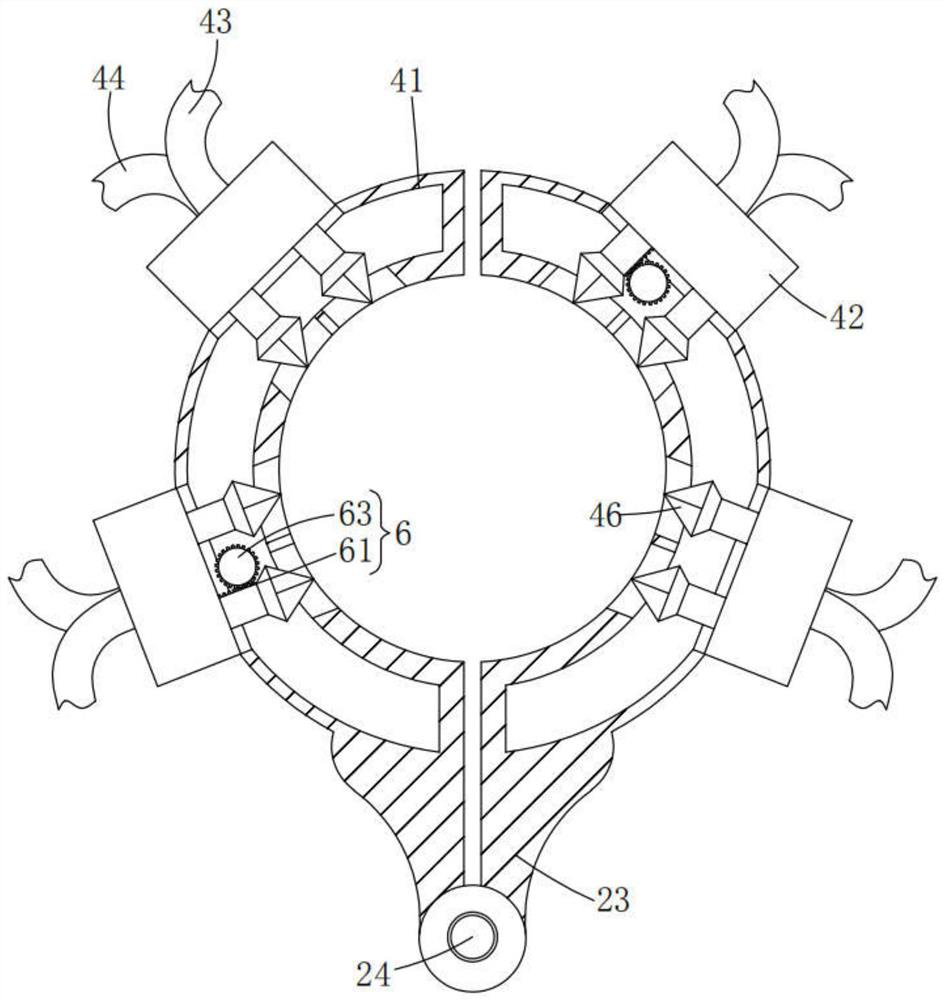

[0029] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 ,in, figure 1 A structural schematic diagram of a preferred embodiment of the reinforced concrete internal support ecological demolition structure and its construction method provided by the present invention; figure 2 for figure 1 The enlarged schematic diagram of part A shown; image 3 for figure 1 Schematic cross-sectional view of the broken column structure shown; Figure 4 for figure 2 A schematic cross-sectional view of the hydraulic tank shown; Figure 5 for figure 1 Schematic cross-sectional view of the collection structure and back cover structure shown; Figure 6 for Figure 5 The enlarged schematic diagram of part B shown; Figure 7 for Figure 6 Schematic diagram of the top cross-section of the collection st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com