Power plant steam turbine professional subsystem debugging plan debugging method

A technology of debugging plan and debugging method, applied in the direction of engine testing, engine components, machines/engines, etc., can solve problems such as waste of human resources, unclear phased goals, and conditions that hinder the normal progress of work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

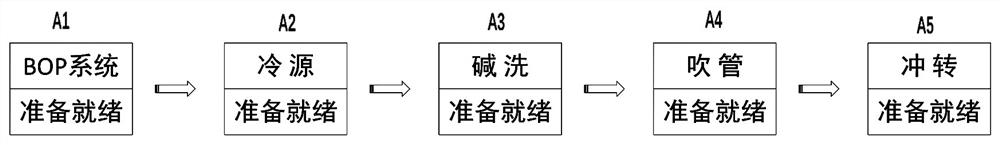

[0262] The present invention provides an embodiment, a method for debugging a specialized sub-system of a steam turbine in a thermal power plant. Level 1 commissioning and Level 3 commissioning phases.

[0263] It specifically includes the following five major steps, that is, the preparation of the first-level commissioning plan, and the following nodes are set as the first-level milestone nodes, including:

[0264] Step 1. The BOP system is ready; the BOP system refers to: Balance Of Plant, which refers to the public system of the power plant, and is the basic support system for the normal operation of other process systems of the power plant.

[0265] Step 2. The cold source is ready; the cold source is ready to be a pre-order node available for commissioning of the compressed air system.

[0266] Step 3. Alkaline washing is ready;

[0267] Step 4. The blowpipe is ready;

[0268] Step 5. Flush is ready.

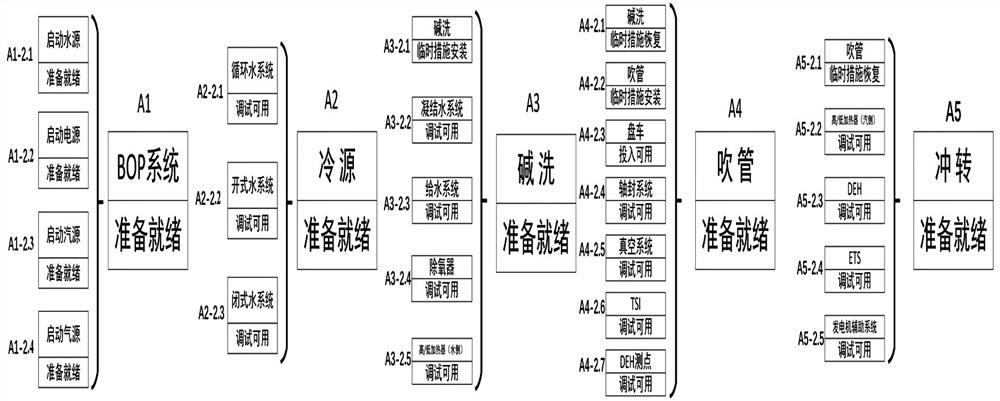

[0269] Further, the step 1. BOP system is ready, including the fol...

Embodiment 2

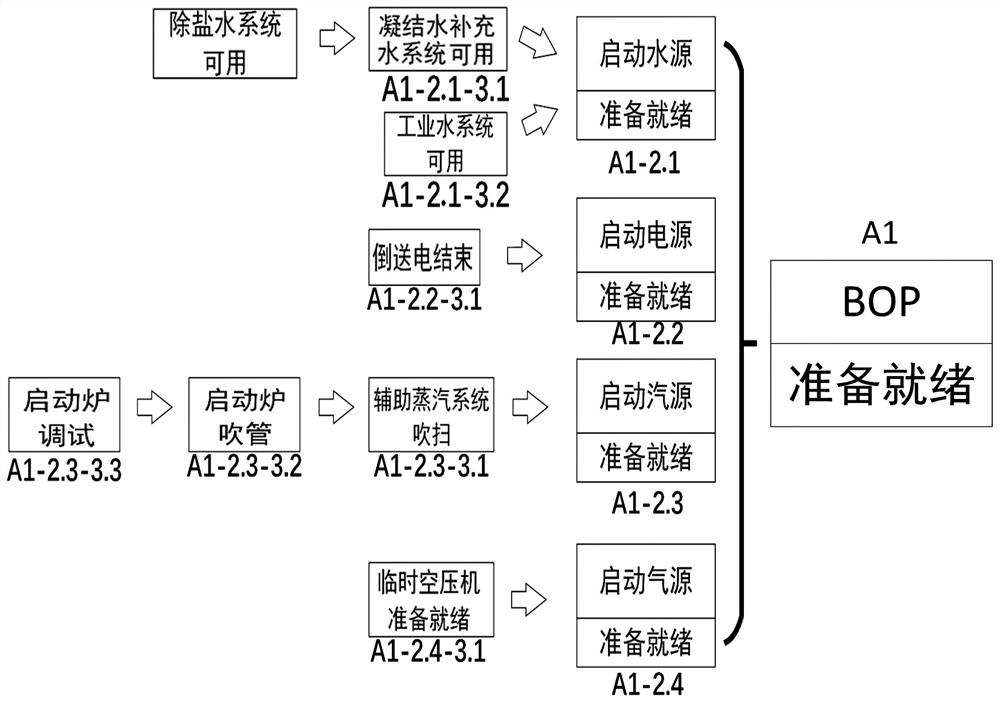

[0319] The present invention provides an embodiment, a method for debugging a thermal power plant steam turbine professional sub-system debugging plan. Further, in the above-mentioned compilation of the first-level debugging plan, the following nodes are set as the second-level milestone nodes. In the step 1 The medium BOP system is ready, including the following two-level milestone nodes, including:

[0320] Step (1) starting the water source is ready;

[0321] Step (2) start the power supply and get ready;

[0322] Step (3) starting the steam source is ready;

[0323] Step (4) The air source is ready to start.

[0324] Wherein, the step (1) starts the water source ready node, including the following three-level milestone nodes: the condensate replenishment water system is available;

[0325] Wherein, the condensate supplementary water system is available, including the following preorder nodes: the desalinated water system is available and the industrial water system is a...

Embodiment 3

[0332] The present invention provides an embodiment, a method for commissioning a thermal power plant steam turbine professional sub-system commissioning plan, further, in the step 2, the cold source is ready, including the following two-level milestone nodes:

[0333] Step (1) circulating water system debugging is available;

[0334] Step (2) open water system debugging is available;

[0335] Step (3) closed water system debugging is available.

[0336] Wherein, the available nodes for debugging of the circulating water system in the step (1) include the following three-level milestone nodes:

[0337] ① Single debugging of circulating water system;

[0338] ②Circulating water system logic test;

[0339] ③ Trial operation of circulating water pump motor unit;

[0340] ④The first test run of the circulating water pump.

[0341] Wherein, the first test run of the circulating water pump includes the following preorder nodes:

[0342] ① Debugging of the hydraulic control but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com