Intelligent measuring device for moisture content of crude oil

A technology for measuring devices and water content, applied in measuring devices, specific gravity measurement, instruments, etc., can solve the problems of poor safety and stability of crude oil water content, low measurement accuracy, high price, etc., and achieve high cost performance and high measurement accuracy , quality and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

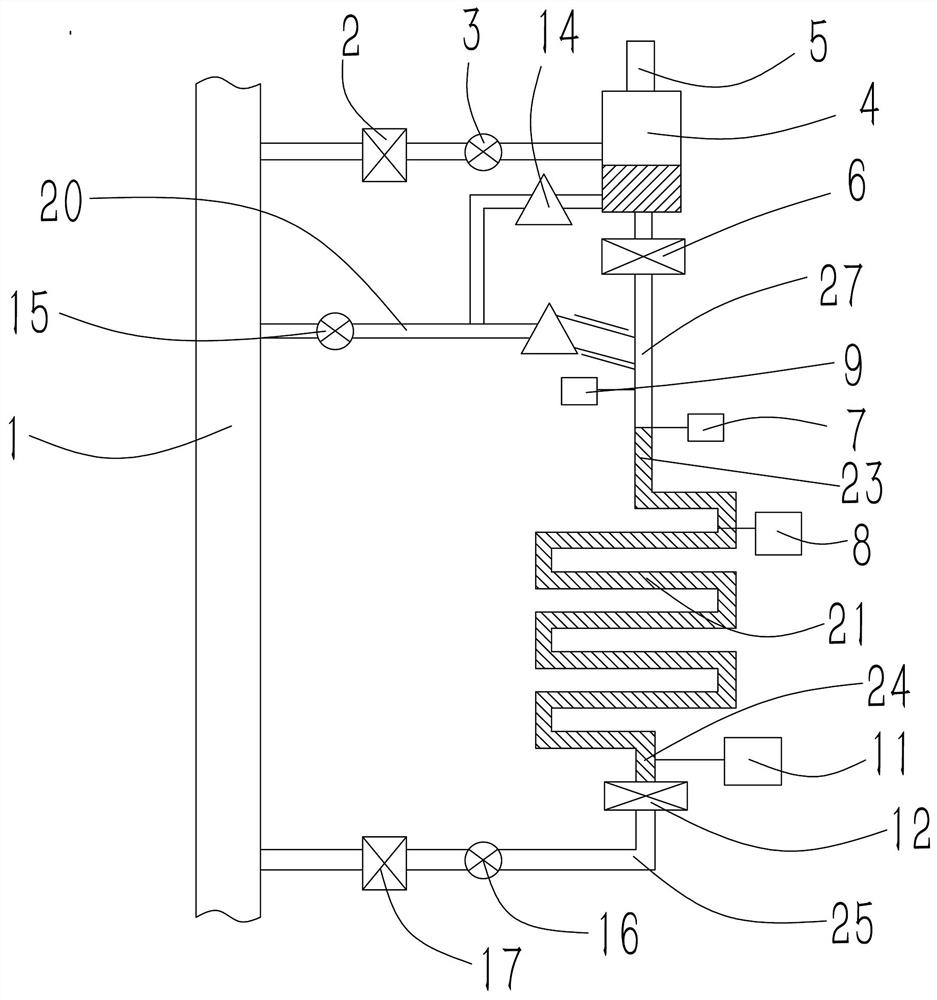

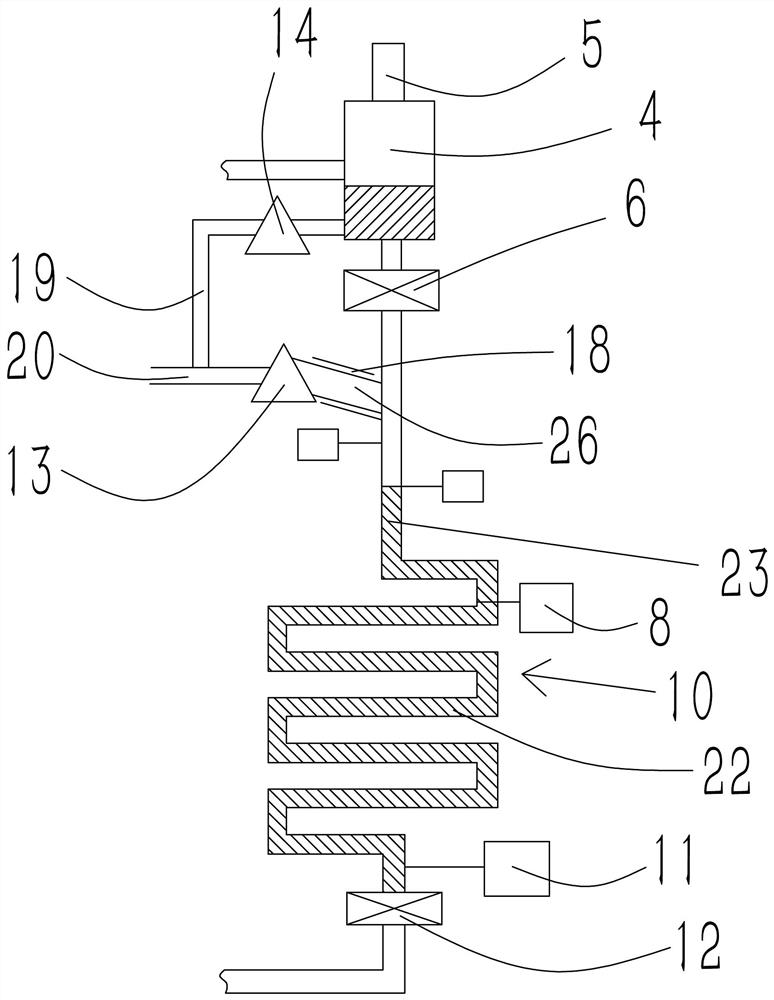

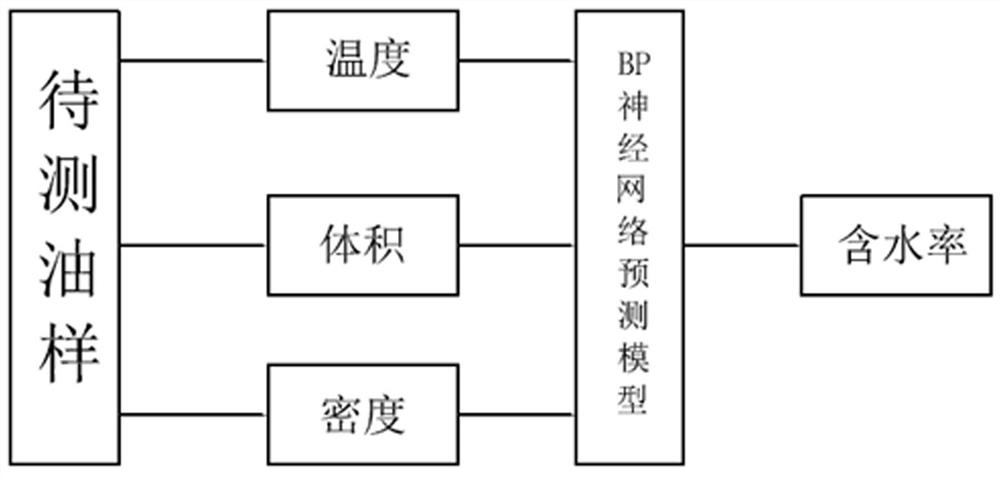

[0027] Such as Figure 1~3 As shown, a crude oil water content measuring device includes a pretreatment container 4, one end of the pretreatment container 4 is connected to the pipeline 1 through a pipeline, and the other end of the pretreatment container 4 is connected to a measurement system 21 through a pipeline, and the measurement system 21 includes from The first pressure sensor 9, the liquid level sensor 7, the temperature sensor 8 and the second pressure sensor 11 are arranged from top to bottom. The end of the measurement system 21 that is closer to the second pressure sensor 11 is provided with a first oil return port 25. The first The oil return port 25 is connected with the pipeline 1 through a pipeline. With this structure, the water content can be measured by the density method and the expansion method at the same time, and the accuracy is higher.

[0028] In a preferred solution, the pipeline between the pipeline 1 and the pretreatment container 4 is provided w...

Embodiment 2

[0038] Working principle: During the measurement process, the electromagnetic one-way valve 2 of the oil inlet is first opened, and the crude oil in the pipeline 1 is pumped into the sampling pretreatment container 4 through the first oil pump 3 for pretreatment. There is a heating unit, and the heating unit is used to remove the gas in the crude oil, and then stir the treated water and oil mixture evenly, and enter the draft pipe 22 through the sampling port switch 6 .

[0039] After entering the measurement device, the high-pressure spray port 5 can be opened and the pretreatment container 4 can be heated to clean the sampling pretreatment container 4 and prepare for the next measurement. After the cleaned liquid passes through the oil return port 19 of the pretreatment container, the electromagnetic one-way valve 14 of the liquid discharge port is opened, and the cleaning liquid is discharged into the pipeline 1 under the action of the return port pump 15 .

[0040]The proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com