Method for calculating effective membrane area of universal reverse osmosis membrane element

A technology of reverse osmosis membrane and calculation method, applied in semi-permeable membrane separation, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc., can solve the scrapping of membrane elements and increase the time and difficulty of obtaining the effective membrane area of membrane elements , increase the cost of obtaining the effective membrane area of the membrane element, etc., to achieve the effect of fast and accurate calculation and reduce the design cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

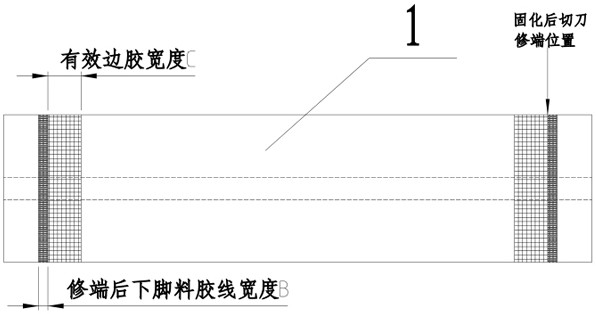

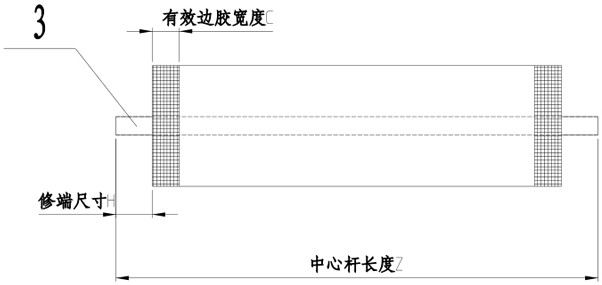

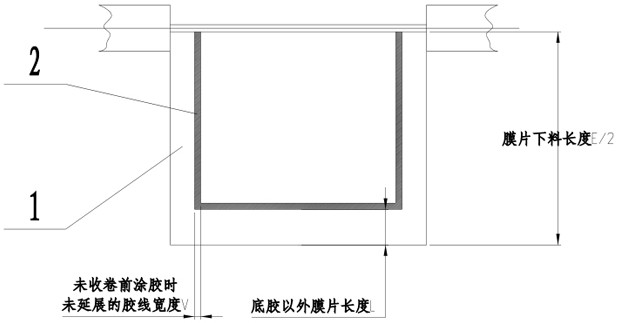

[0031] refer to Figure 1-3 As shown, a method for calculating the effective membrane area of a general-purpose reverse osmosis membrane element includes the following steps:

[0032] Step 1: Determine the dimensional parameters of the membrane element 1Q; the dimensional parameters include the length Z of the central rod 3 of the membrane element 1, the trimming size H, the page number J of the membrane element 1, and the length E of the membrane blanking;

[0033] Step 2: Determine the width A of the total glue line 2 after winding, the width B of the leftover glue line 2 after trimming, and the length L of the diaphragm outside the primer; when determining the width of each glue line 2 for the first time, the values of A, B, and L can be determined by Formula 1, Formula 2, Formula 3 to determine:

[0034] Formula 1: A=V*6

[0035] Formula 2: L=A / 2

[0036] Formula 3: B=(B1+B2+B3+…Bn) / n

[0037] Among them, V represents the width of the unextended glue line 2 when ...

Embodiment 2

[0045] Embodiment 2 includes all the technical features in Embodiment 1, specifically including:

[0046] A method for calculating the effective membrane area of a general-purpose reverse osmosis membrane element includes the following steps:

[0047] Step 1: Determine the dimensional parameters of the membrane element 1Q; the dimensional parameters include the length Z of the central rod 3 of the membrane element 1, the trimming size H, the page number J of the membrane element 1, and the length E of the membrane blanking;

[0048] Step 2: Determine the width A of the total glue line 2 after winding, the width B of the leftover glue line 2 after trimming, and the length L of the diaphragm outside the primer; when determining the width of each glue line 2 for the first time, the values of A, B, and L can be determined by Formula 1, Formula 2, Formula 3 to determine:

[0049] Formula 1: A=V*6

[0050] Formula 2: L=A / 2

[0051] Formula 3: B=(B1+B2+B3+…Bn) / n

[0052] Am...

Embodiment 3

[0060] Embodiment three includes all technical characteristics in embodiment two, specifically includes:

[0061] A method for calculating the effective membrane area of a general-purpose reverse osmosis membrane element includes the following steps:

[0062] Step 1: Determine the dimensional parameters of the membrane element 1Q; the dimensional parameters include the length Z of the center rod 3 of the membrane element 1, the trimming dimension H, the page number J of the membrane element 1, the cutting length E of the membrane, and the trimming dimension H refers to the central rod 3 The distance from the outermost side to the end face of the film roll on the same side;

[0063] Step 2: Determine the width A of the total glue line 2 after winding, the width B of the leftover glue line 2 after trimming, and the length L of the diaphragm outside the primer; when determining the width of each glue line 2 for the first time, the values of A, B, and L can be determined by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com