Insulation treatment process for induction heating load coil

A load coil and induction heating technology, which is applied in coil manufacturing, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of destroying the insulation of insulating materials, difficulty in controlling the quality of winding, loosening and falling off of insulating materials, etc., to achieve guarantee Insulation ability, excellent heat dissipation, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

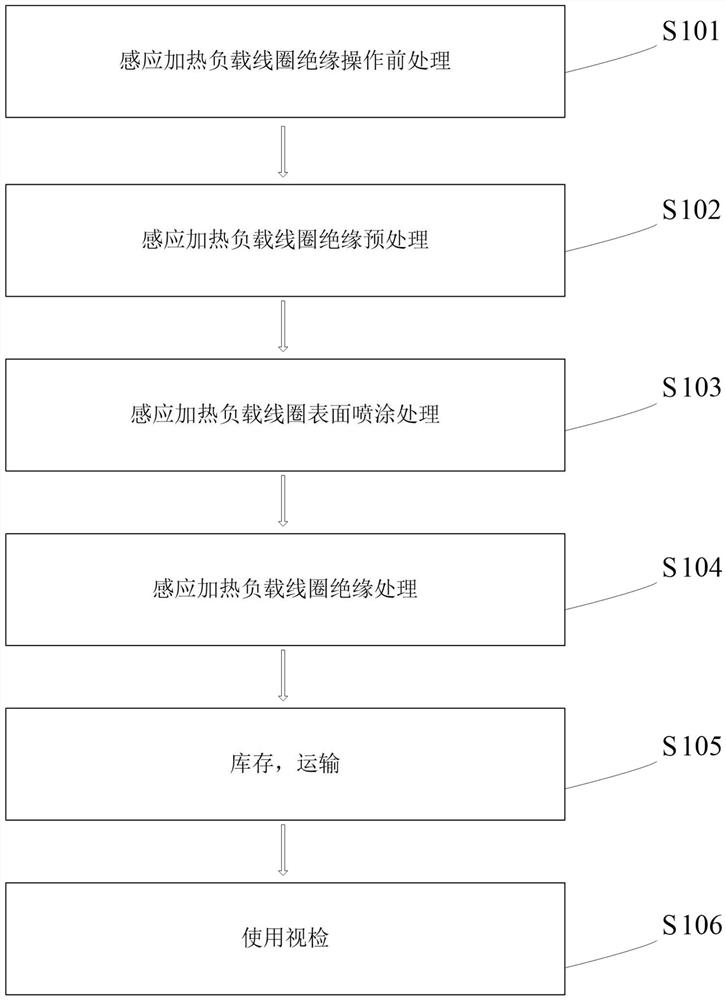

[0063] 1. Before the insulation operation of the induction heating load coil, clean the surface of the induction heating load coil, brush and clean the dust and impurities on the surface of the induction heating load coil with a nylon brush, and check whether there is any dust on the surface of the induction heating load coil. Damaged or leaking core problems, and repair or cut in time, then blow the induction heating load coil through a hair dryer to remove moisture, clean up the whole, let it stand, and set aside;

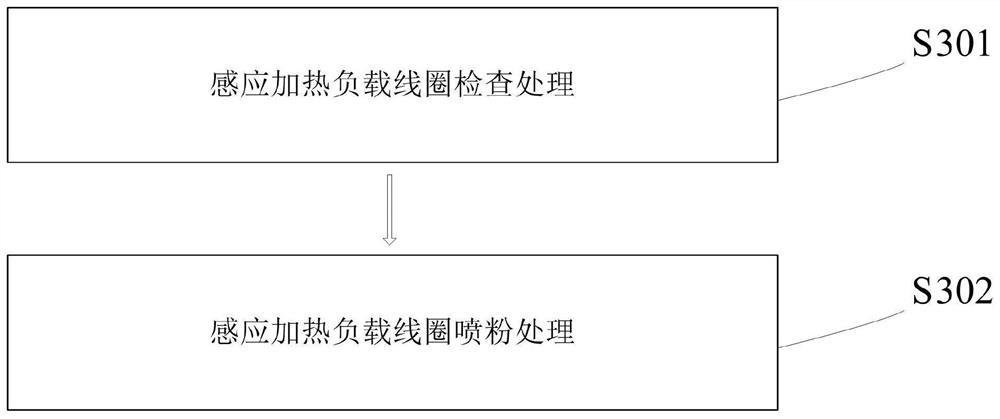

[0064] 2. Insulation pretreatment of induction heating load coil, the specific operation process should be carried out in accordance with the following steps:

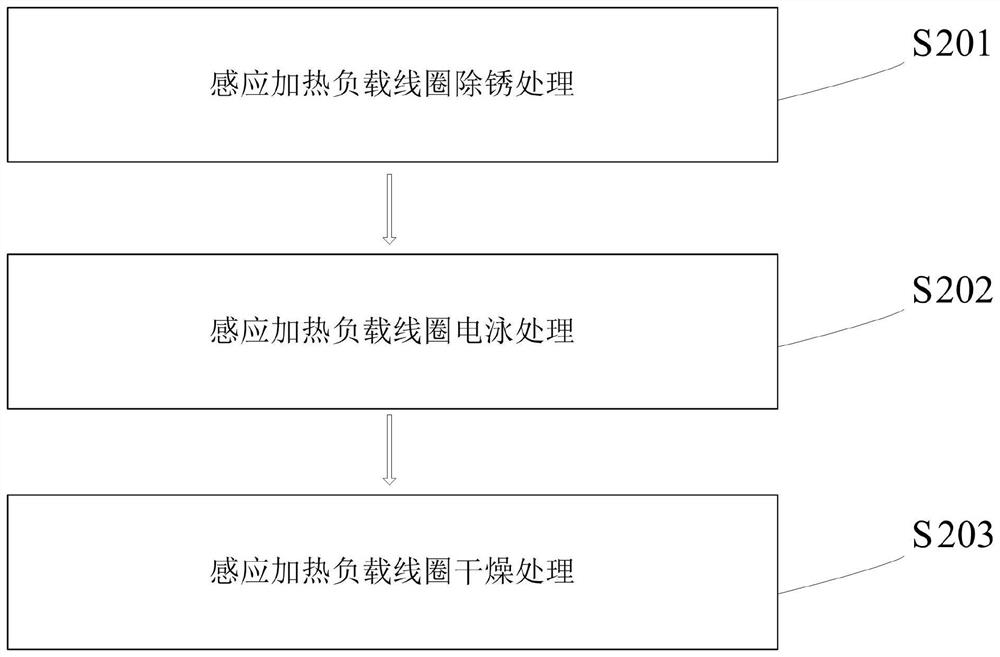

[0065] Step 1: Derusting the induction heating load coil, preparing the derusting agent, pouring the derusting agent into the derusting tank, stirring, and then dipping the derusting agent with a brush and lightly applying it on the surface of the induction heating load coil to carry out For derusting ope...

specific Embodiment 2

[0078] 1. Before the insulation operation of the induction heating load coil, clean the surface of the induction heating load coil, brush and clean the dust and impurities on the surface of the induction heating load coil with a nylon brush, and check whether there is any dust on the surface of the induction heating load coil. Damaged or leaking core problems, and repair or cut in time, then blow the induction heating load coil through a hair dryer to remove moisture, clean up the whole, let it stand, and set aside;

[0079] 2. Directly adopt the method of spraying insulation material layer for insulation operation treatment;

[0080] 3. Rust spots or magnetic flux leakage problems are prone to occur during use.

[0081] Based on the above comparison, it can be seen that the present invention utilizes newer insulating materials, and improves the insulation level to provide a strong insulation guarantee for high-voltage loads, and at the same time improves the stability of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com