Automatic insulated wire coating robot

A technology of automatic coating and insulating wire, applied in the direction of manipulator, overhead line/cable equipment, manufacturing tools, etc., can solve the problem of long line power outage, affecting the reliability index of overhead line, and high danger of personnel climbing operation. The reliability of power supply can be improved, direct drip exposure is avoided, and the insulating layer structure is uniform and complete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to deepen the understanding of the present invention, the present invention will be described in further detail below with reference to the embodiments. The embodiments are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

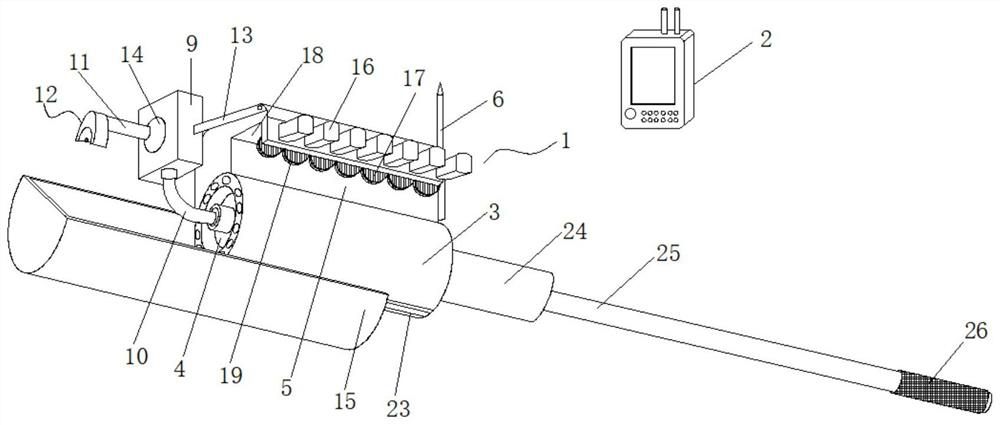

[0017] according to figure 1 , 2 , 3, the present embodiment proposes that in order to achieve the purpose of the present invention, the present invention is realized through the following technical solutions:

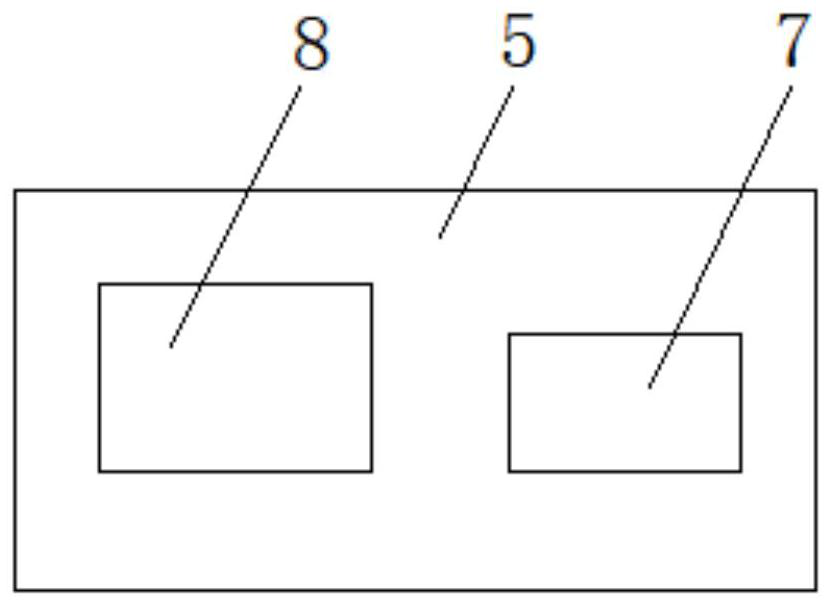

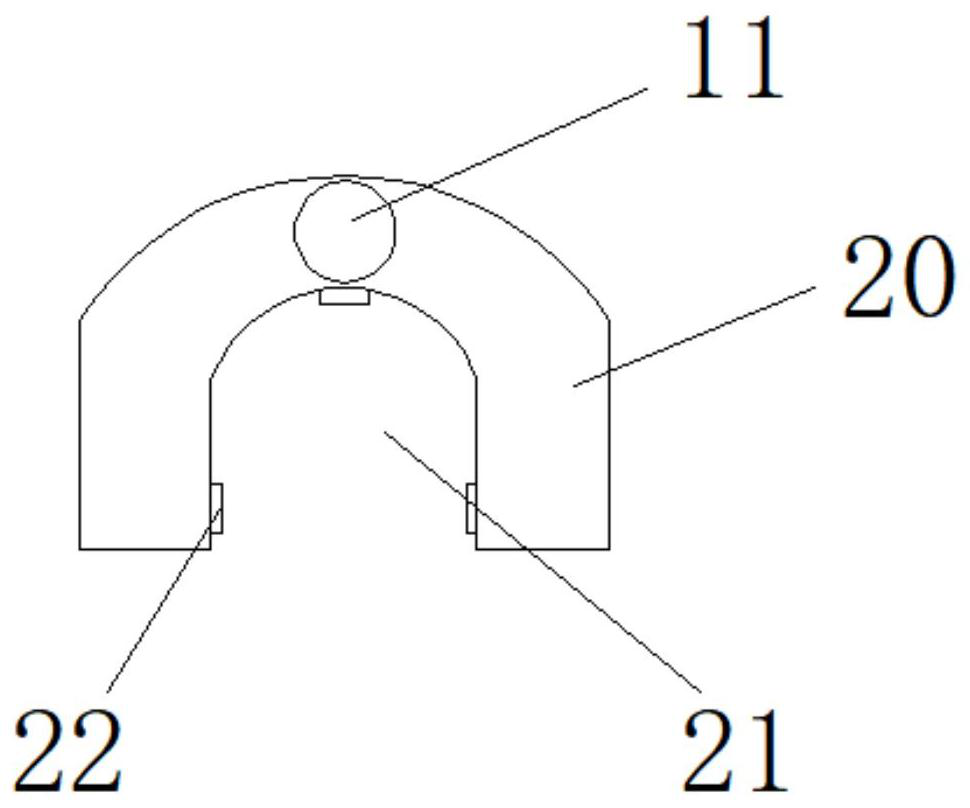

[0018] The insulated wire automatic coating robot includes a robot body 1 and a remote control 2. The remote control 2 is used to control the robot body 1. The robot body 1 includes a body 3, a paint bucket 4, a walking mechanism, a nozzle assembly and a guide assembly , the fuselage 3 is provided with a main box 5, the main box 5 is provided with an antenna 6, one side of the main box 5 is provided with a walking mechanism, and the main box 5 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com