Rice flour machine for processing coarse cereal, fruit and vegetable whole-flour raw materials

A rice noodle machine and grain technology, which is applied in application, food science, food forming, etc., can solve the problems of hard powder texture, hindering material push, easy to block the discharge channel, etc., to improve fluidity, reduce friction, Guaranteed full softening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

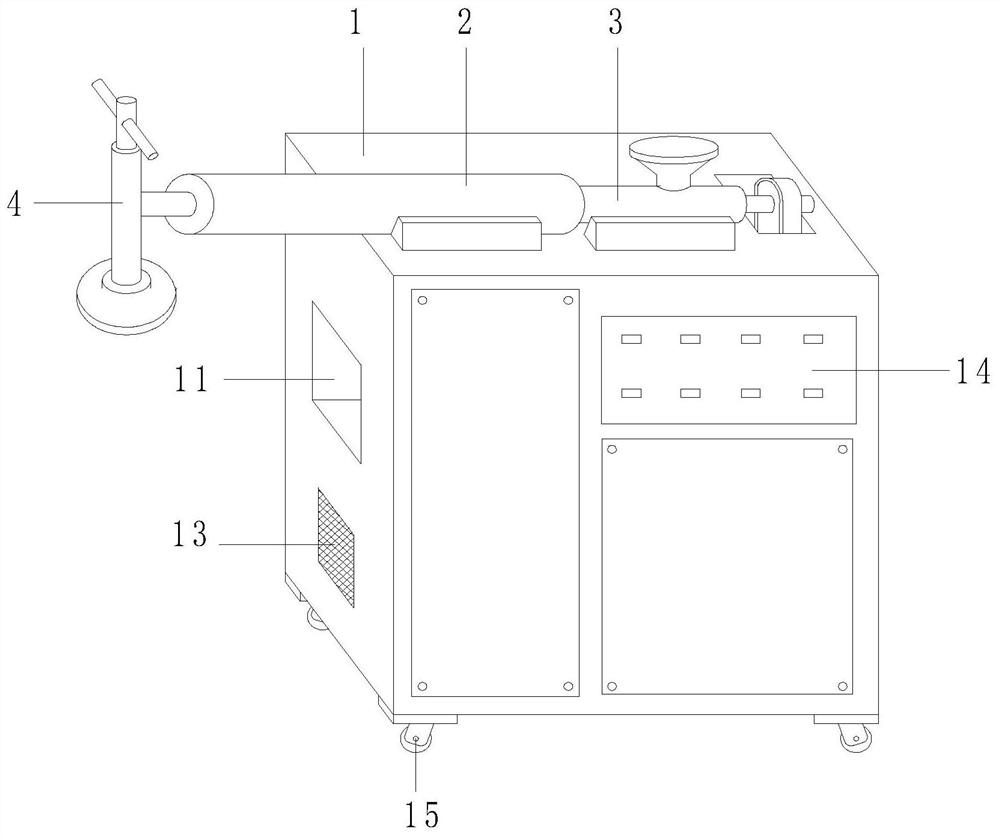

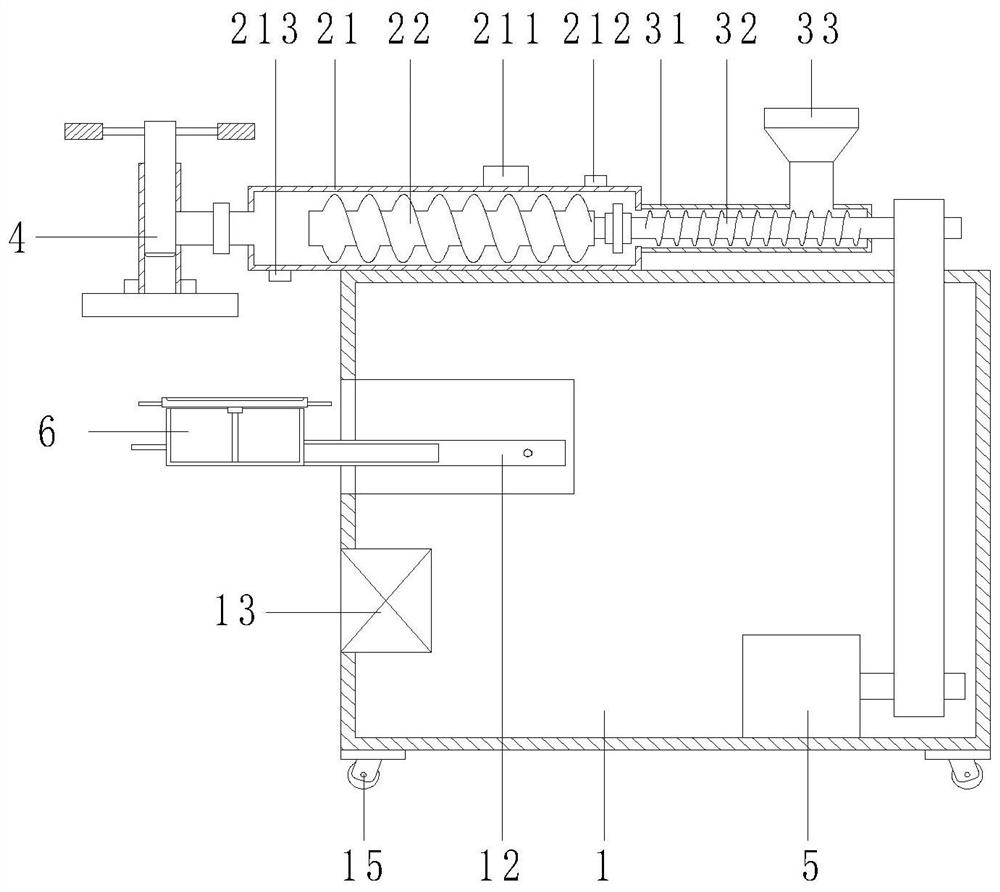

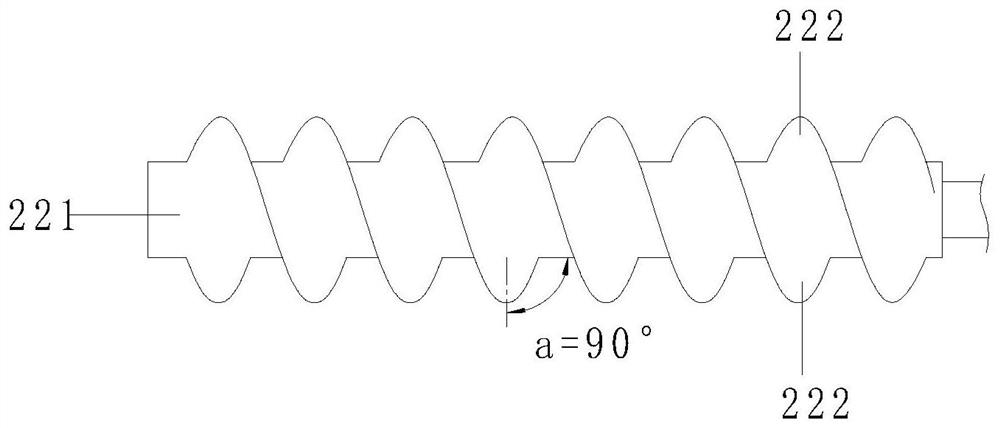

[0031] Such as Figure 1 to Figure 8 As shown, a kind of rice noodle machine that is used for raw material processing of miscellaneous grains, fruits and vegetables, comprises body 1, processing device 2, feeding device 3, powder discharging device 4, drive motor 5 and powder taking device 6, in the present embodiment The processing device 2 includes an extrusion cylinder 21 and a screw 22 , the extrusion cylinder 21 is fixed on the upper surface of the body 1 and extends to the outside of the body 1 , and the screw 22 is housed in the extrusion cylinder 21 . Such as image 3 As shown, the screw 22 includes a rotating shaft 221 and two helical blades 222 that cross and symmetrically distribute on the rotating shaft 221 . The inclination angle a is 90° to reduce the influence of the radial thrust of the spiral end surface on the running state of the material, so that the material mainly moves along the axial thrust direction, reduce the friction between the material and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com