Fertilizer stirring device for compound fertilizer production

A technology of mixing device and compound fertilizer, which is applied to mixers with rotary mixing devices, accessories of mixers, mixers, etc., can solve the problems of reducing product quality, affecting the mixing effect of the device, and single mixing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

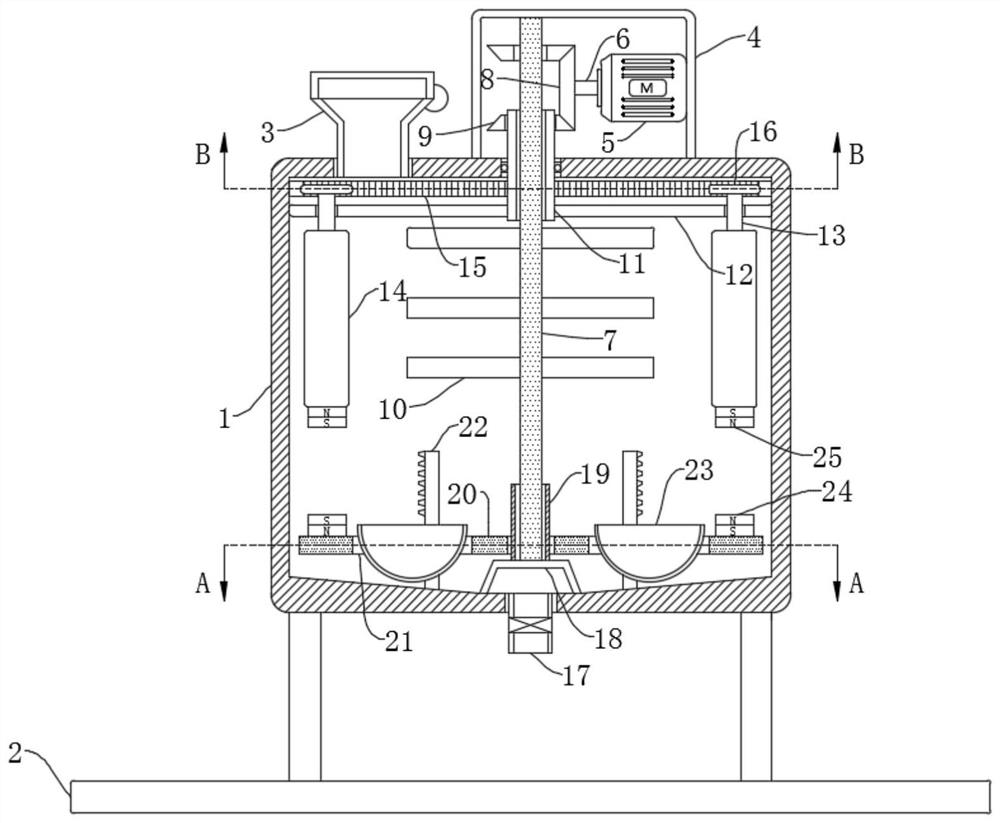

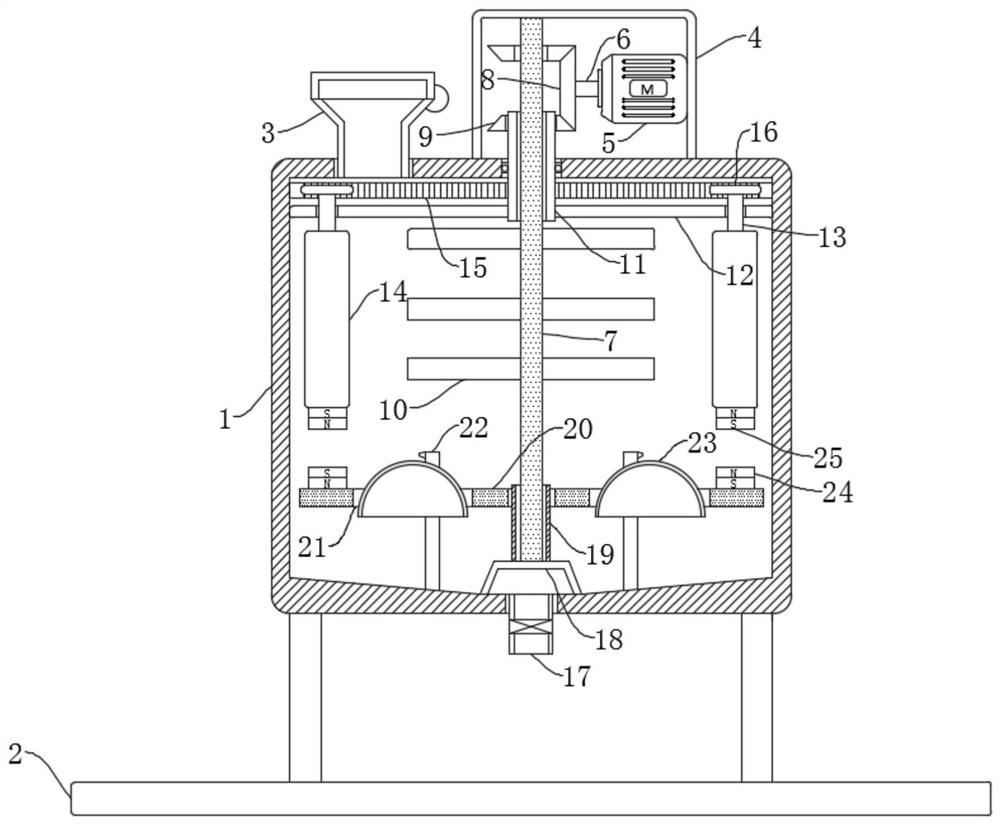

[0033] refer to Figure 1-4 , a fertilizer mixing device for compound fertilizer production, comprising a bottom plate 2, four support columns are fixedly connected to the upper wall of the bottom plate 2, a mixing box 1 is fixedly connected to the upper ends of the four support columns, and the upper wall of the mixing box 1 is connected with a feeding Pipe 3, feeding pipe 3 is in the shape of a funnel, the side wall of feeding pipe 3 is hinged and connected with a cover, which can prevent the fertilizer solution from splashing outside the mixing box 1 during the stirring process, and the lower wall of the mixing box 1 is connected with a discharge pipe 17. The discharge pipe 17 is provided with a solenoid valve.

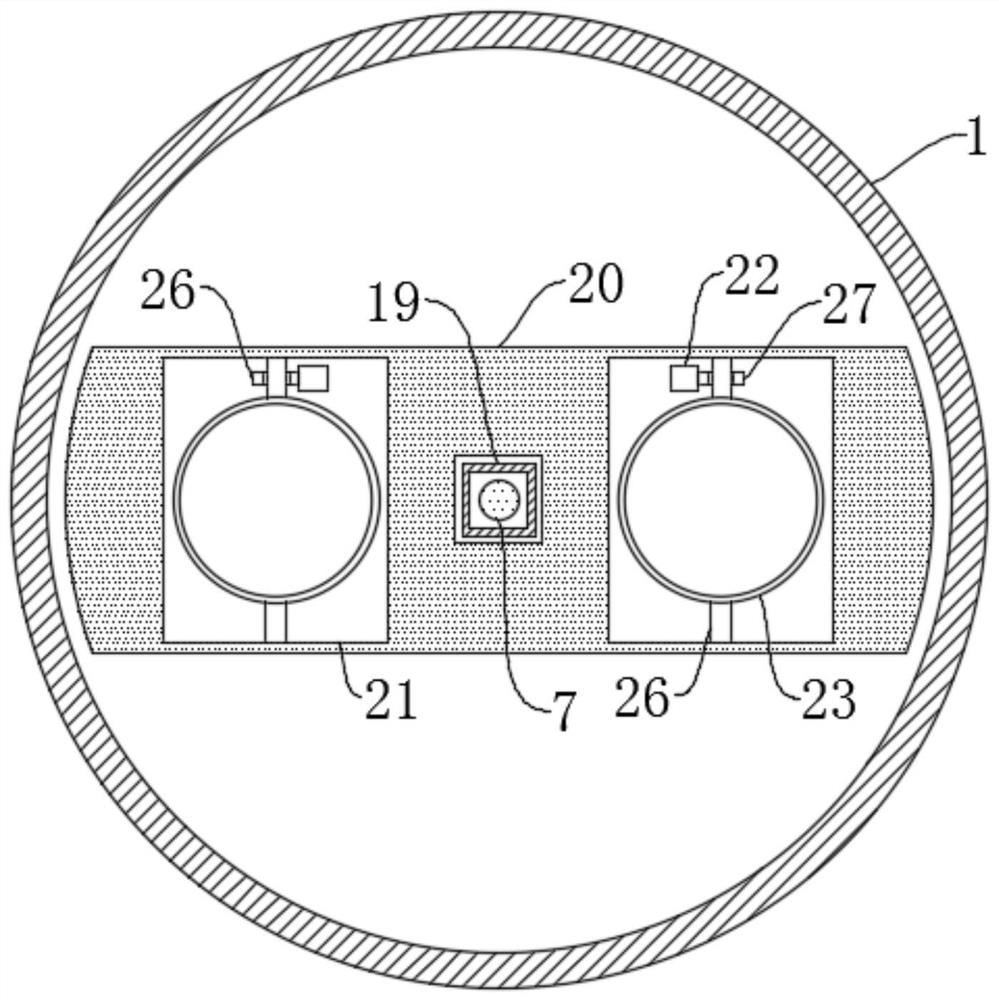

[0034] The stirring box 1 is provided with a stirring mechanism, the stirring mechanism includes a fixed plate 18 fixedly connected to the inner bottom of the stirring box 1, the upper wall of the fixed plate 18 is rotatably connected with a rotating rod 7, and the...

Embodiment 2

[0046] refer to Figure 5 , different from Embodiment 1, the side wall of the mixing tank 1 is fixedly connected with a heat pipe 31, and the material of the heat pipe 31 is made of copper, which has a good heat conduction effect. The inner wall of the 28 is sealed and slidably connected with a piston 29 , the upper end of the piston 29 is fixedly connected with a moving rod 30 , and the upper end of the moving rod 30 is fixedly connected with the lower wall of the moving plate 20 .

[0047] The upper wall of the bottom plate 2 is fixedly connected with a heating box 32, and the heating box 32 is filled with heat-conducting oil, which is a kind of special oil product with good thermal stability for indirect heat transfer, and has the advantage of uniform heating. The inner top of 32 is fixedly connected with a heating rod 33, one end of the heat pipe 31 communicates with the fixed cylinder 28 through the water outlet pipe 35, and the end of the heat pipe 31 away from the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com