Stamping device

A stamping device and punch technology, which is applied in the field of stamping devices, can solve problems such as bending deformation, affecting personal safety, and high probability of safety accidents, so as to prevent bending and deformation, ensure personal safety, and have a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

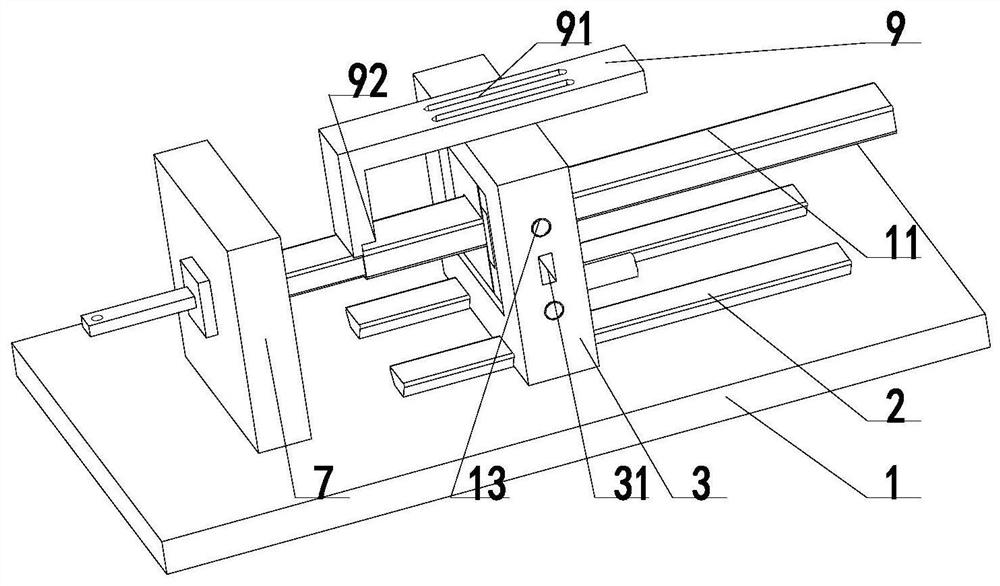

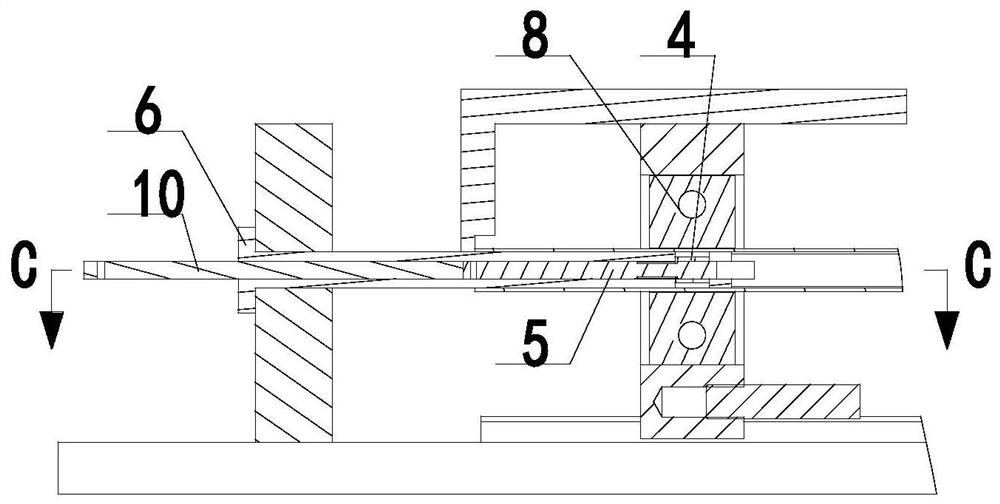

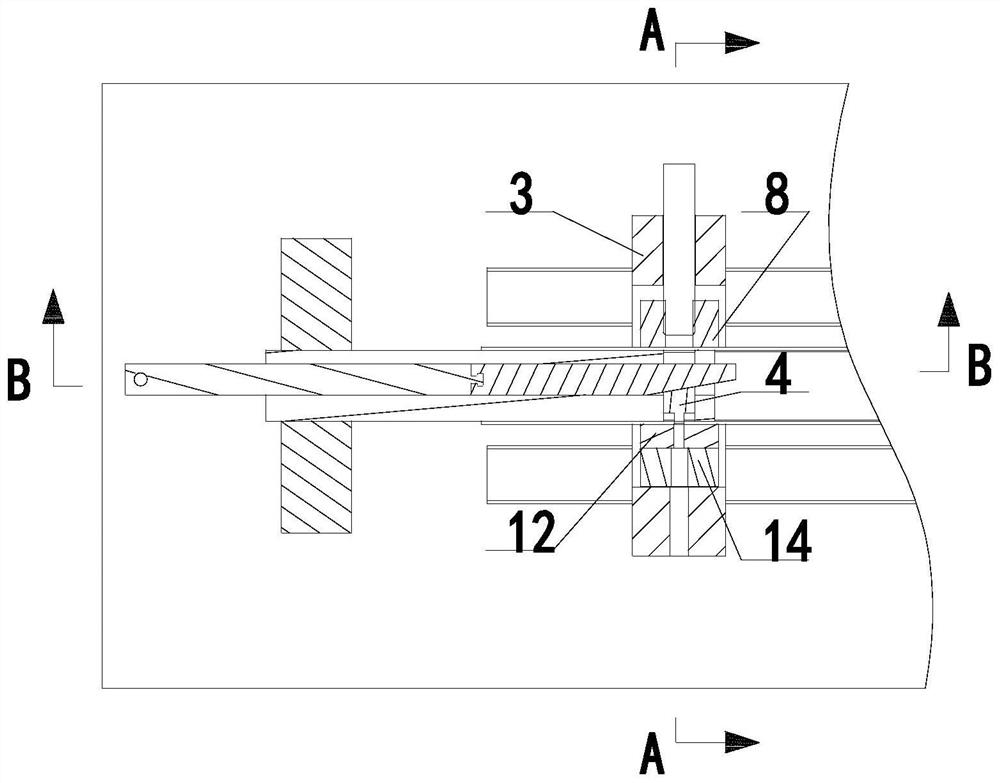

[0027] Such as Figure 1-11 As shown, the present invention is a stamping device.

[0028] The stamping device described in this embodiment includes a platen 1, the two ends of the platen 1 are respectively provided with a fixed block 7 and a guide rail 2, the shape of the section of the guide rail 2 is dovetail shape, and the guide rail 2 is provided with a slide Shift seat 3, slide seat 3 is the structure of intermediate cavity, connects power source on the slide seat 3, and described power source is hydraulic cylinder, because the connection mode of hydraulic cylinder is prior art, no longer expands here. The fixed block 7 is covered with a sheath 6, the sheath 6 is a hollow structure, the sheath 6 is a wear-resistant metal material, the workpiece 11 is sleeved on the sheath 6, and the outer dimension of the sheath 6 is slightly larger tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com