Shockproof automobile stamping die

A technology for stamping dies and automobiles, applied in the field of stamping dies, can solve problems such as poor shockproof effect and affect service life, and achieve the effects of convenient replacement, improved friction, and improved convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

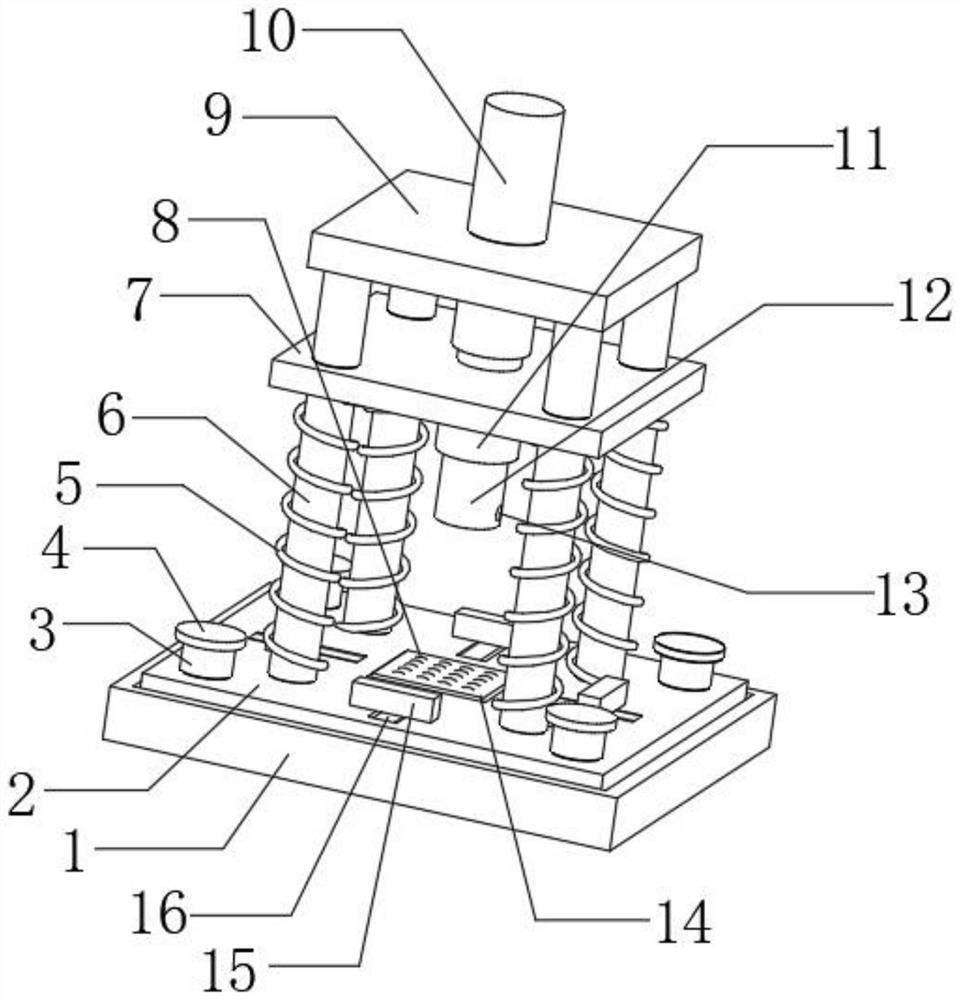

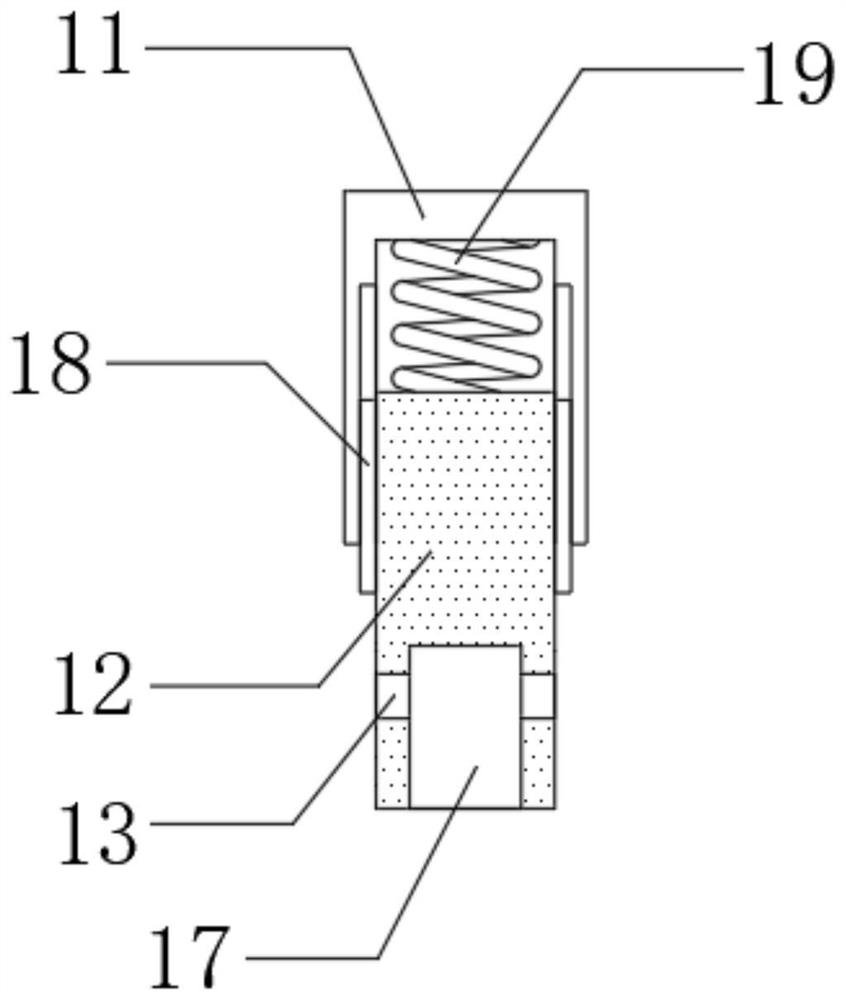

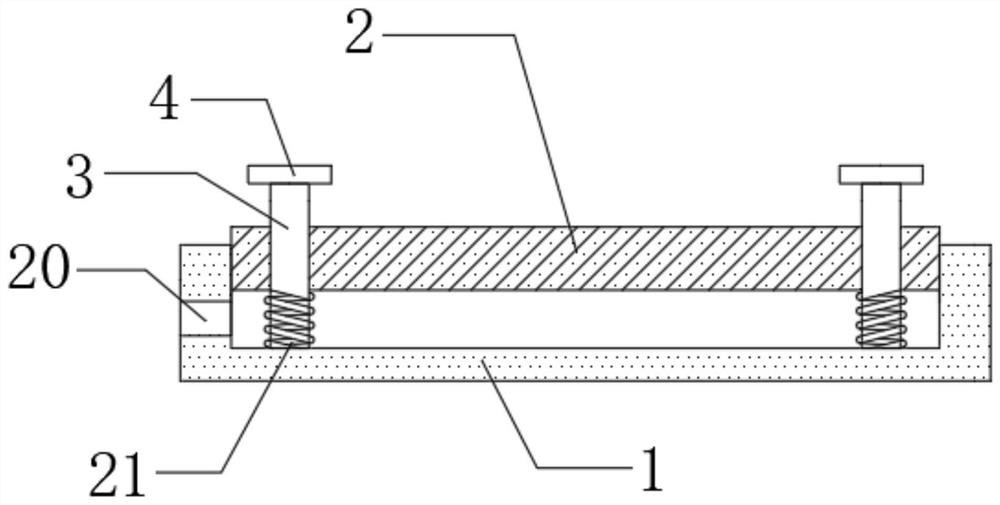

[0028] refer to Figure 1-3 , a shockproof automobile stamping die, comprising a support base 2, the outer walls of the top four corners of the support base 2 are connected with vertically arranged second limit rods 6 by bolts, and the top outer walls of the four second limit rods 6 are connected by bolts The same support top plate 9 is connected, and the top central outer wall of the support top plate 9 is provided with a first opening, the inner wall of the first opening is connected with a vertical hydraulic cylinder 10 by bolts, and the bottom outer wall of the hydraulic cylinder 10 is connected with a second opening by bolts. A support plate 7, and the top four corner outer walls of the first support plate 7 are provided with second openings, the inner walls of the four second openings are respectively slidingly connected with the circumferential outer walls of the four second limit rods, the first support plate 7 The central outer wall of the bottom is connected with a s...

Embodiment 2

[0038] refer to figure 1 , 2 And 4, a shockproof automobile stamping die, also includes the same annular water storage shell 23 installed on the bottom of the outer wall around the supporting groove plate 1 by bolts, and the exhaust hole 20 is replaced by a water guide pipe 22.

[0039] Working principle: When in use, set the exhaust hole as a water guide pipe, and set the same annular water storage shell on the outer wall around the supporting channel plate, so that clean water can be injected inside the supporting channel plate. During the stamping process, the water flow It is extruded through the water pipe, and then the water pressure realizes the buffering effect, and then achieves the shockproof effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com