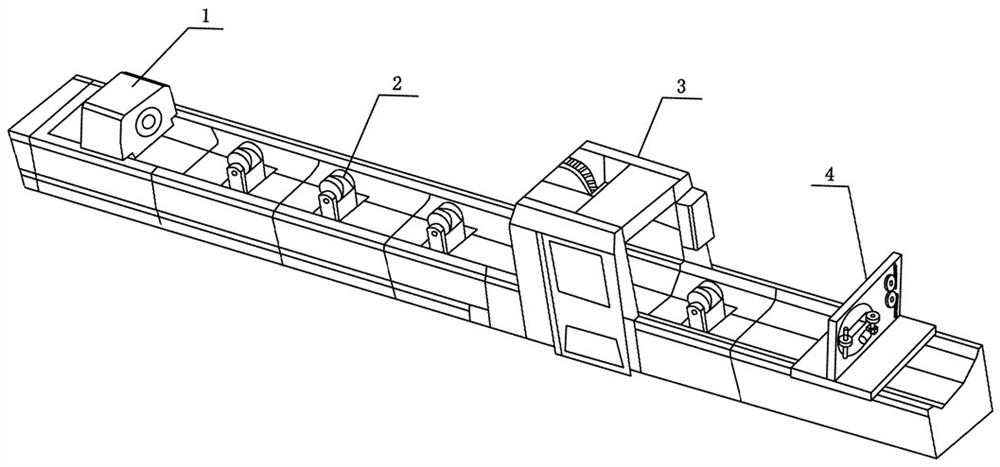

Steel pipe discharging auxiliary device and steel pipe laser drilling cutting machine

An auxiliary device and material cutting technology, which is applied in the direction of auxiliary devices, laser welding equipment, auxiliary welding equipment, etc., can solve the problems such as the inconvenience of pipe materials, and achieve the effect of improving processing accuracy and facilitating material retrieving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

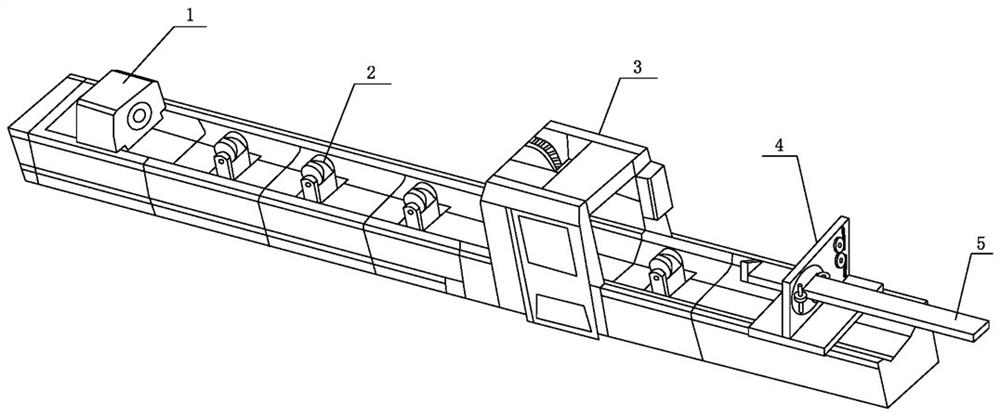

[0035] As mentioned above, the steel pipe laser drilling and cutting machine works on the following principles:

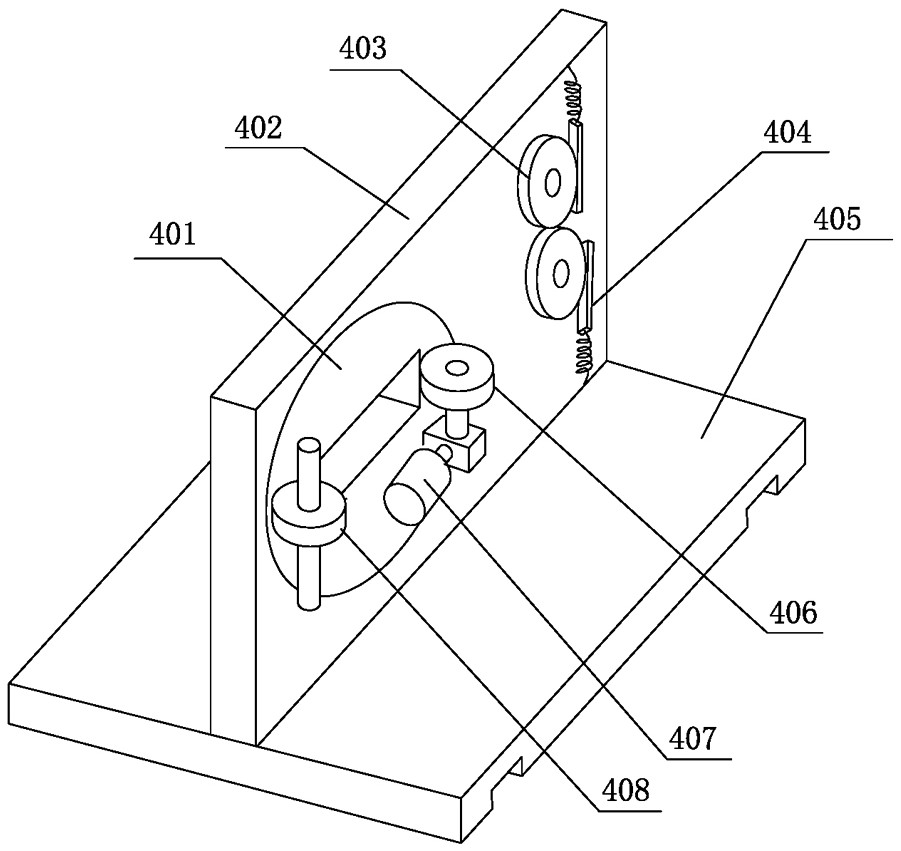

[0036] The clamping chuck clamps the pipe and pushes it forward. The pipe slides forward along the support wheel 2 and passes through the centering chuck. At the same time, the steel pipe unloading auxiliary device 4 slides to the preset position under the action of external force. When passing through the centering chuck and then entering between the two clamp arms 411, move the clamp arm 411 by hand to make the gap between the two clamp arms 411 larger. After the pipe material enters between the two clamp arms 411, loosen the grip The clamp arm 411 can clamp the pipe material.

[0037]The two clamping gears 403 mesh with each other. When the clamping arms 411 are moved, no matter whether one of the clamping arms 411 is moved or both clamping arms 411 are moved at the same time, the opening range of the two clamping arms 411 is the same.

[0038] In the initial s...

Embodiment 2

[0043] Such as Figure 7 As shown, in the steel pipe laser drilling and cutting machine mentioned above, the vertical plate 402 is also provided with an electric push rod 412 that expands and contracts under external control, and the upper end of the extension part of the electric push rod 412 is connected with a plectrum , The reset rack 404 is provided with a protrusion that cooperates with the plectrum, and the initial state of the plectrum is out of contact with the protrusion of the reset rack 404 .

[0044] The working principle is:

[0045] The clamping chuck clamps the pipe and pushes it forward. The pipe slides forward along the support wheel 2 and passes through the centering chuck. At the same time, the steel pipe unloading auxiliary device 4 slides to the preset position under the action of external force. When passing through the centering chuck and then entering between the two clamp arms 411, the extension part of the electric push rod 412 stretches out, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com