Alloyed high-strength IF steel plate process control module with excellent powdering performance

A process control and alloying technology, applied in metal material coating process, hot dipping process, improvement of process efficiency, etc. Wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

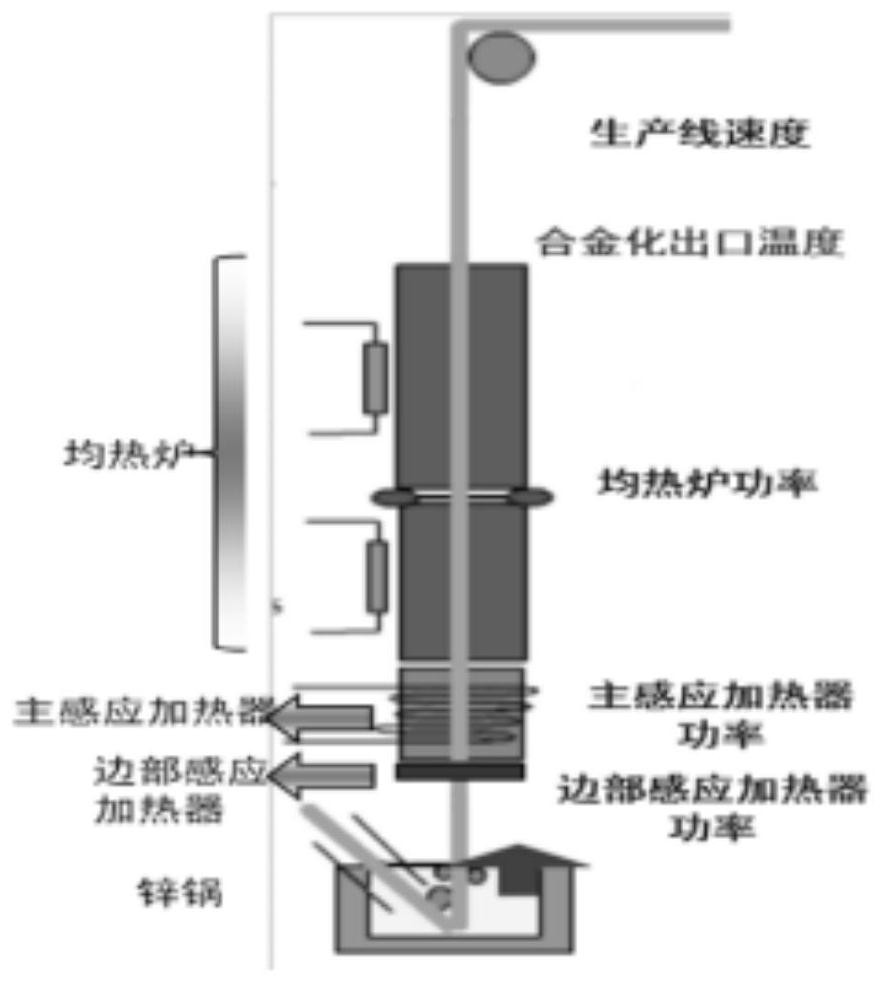

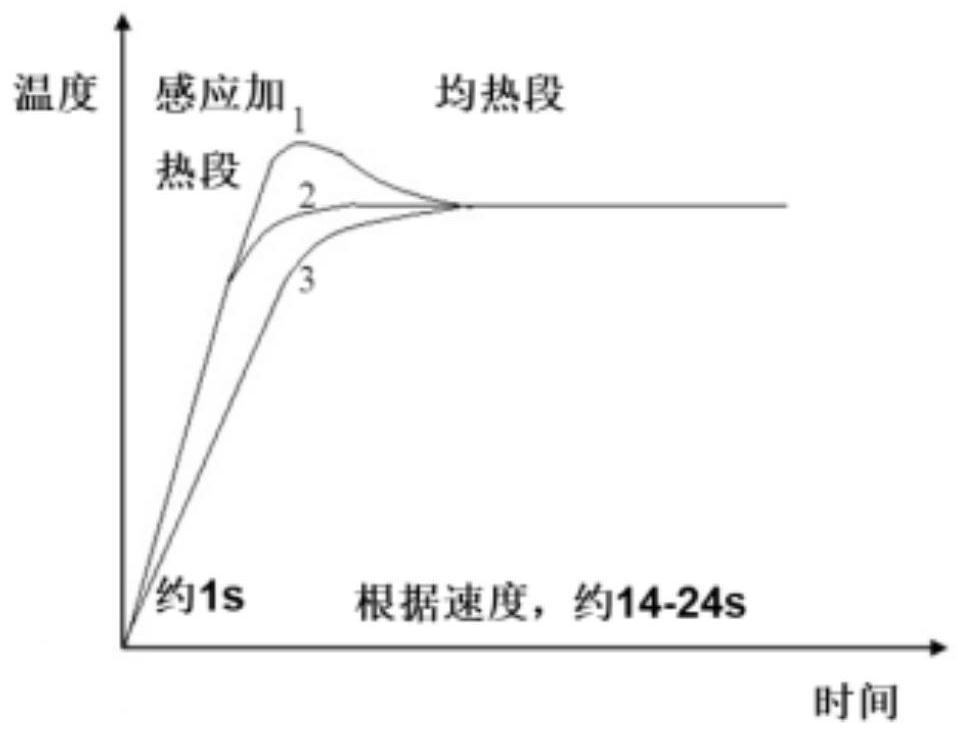

[0061] A process control model of an alloyed high-strength IF steel plate with excellent pulverization resistance of the present invention comprises the following steps:

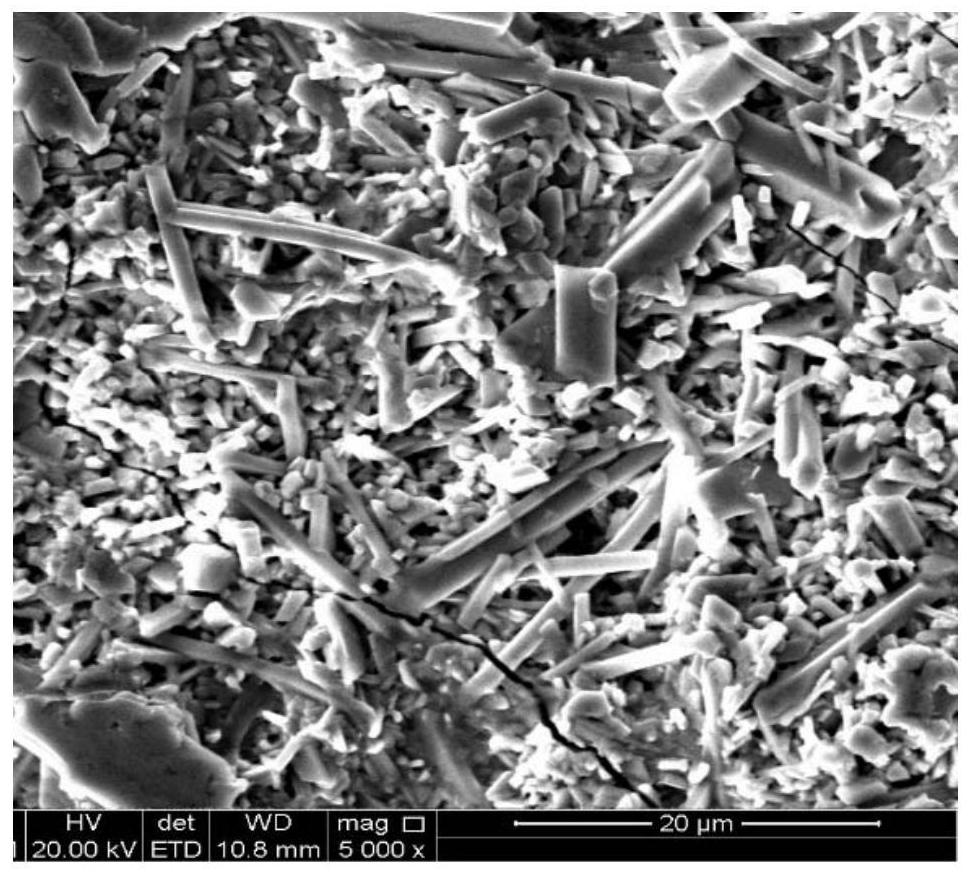

[0062] A. Determination of the optimal process parameters of zinc-iron alloy IF steel plate with specified minimum yield strength, extremely narrow and extremely thin specifications; on-line debugging of 0.5mm*900mm specification, the best alloying process of zinc-iron alloy high-strength IF steel plate with minimum yield strength of 180MPa, obtained The optimal alloying process of zinc-iron alloy high-strength IF steel plate of this specification was obtained. The power of the main induction heater is 830KW, and the power of the edge induction heater is 120KW. The product structure and Fe content produced by this process are as follows: Figure 3-6 As shown, it means that the product has excellent anti-powdering performance under this process condition. The surface phase composition of the middle part and...

Embodiment 2

[0078] On the basis of Example 1, this embodiment provides on-line tracking of 40 volumes of 180MPa level zinc-iron alloy high-strength IF steel, about 3000 tons of the above-mentioned specification zinc-iron alloy high-strength IF steel (ZF90 coating weight) production situation, its target product parameters are as shown in Table 2 shown.

[0079] Table 2 Target parameters of zinc-iron alloy products with 180MPa strength level

[0080] Numbering Width (mm) Thickness (mm) P content (wt%) 1 1555 0.8 0.0331 2 1210 0.7 0.0327 3 990 0.7 0.0386 4 1450 0.8 0.035 5 1280 0.8 0.035 6 1250 1.5 0.0327 7 1550 0.6 0.0354 8 1450 0.8 0.0375 9 1530 0.7 0.0352 10 1555 0.8 0.0331 11 1580 0.6 0.0354 12 1530 0.7 0.0352 13 1300 1.75 0.0397 14 1250 1.5 0.034 15 1180 1 0.0334 16 1325 1.5 0.0334 17 1500 1.99 0.0352 18 1445 0.7 0.0337 19 925 1 0.0386 ...

Embodiment 3

[0086] Present embodiment provides on-line tracking 40 volumes of 220MPa level zinc-iron alloy high-strength IF steels on the basis of embodiment 1, the production situation of about 3000 tons of above-mentioned specification zinc-iron alloy IF steels (ZF90 coating weight), and its target product parameters are as shown in table 4 Show.

[0087]Table 4 Target parameters of 220MPa strength grade zinc-iron alloy products

[0088] Numbering Width (mm) Thickness (mm) P content (wt%) 1 1054 0.55 0.0465 2 1150 0.6 0.052 3 1352 0.65 0.0495 4 1245 1.47 0.0745 5 1257 0.7 0.047 6 1160 0.7 0.05 7 1430 0.7 0.0475 8 1295 0.73 0.0493 9 1472 1.99 0.0481 10 1262 0.75 0.0481 11 1702 0.8 0.0482 12 1570 1 0.0474 13 1630 0.8 0.0529 14 1540 0.8 0.0507 15 1203 0.8 0.0477 16 1095 1 0.044 17 900 0.8 0.0507 18 1475 0.9 0.0482 19 1253 0.9 0.0479 20 162...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com