Bamboo charcoal fiber and polyester blended yarn mixing equipment

A technology of mixing equipment and bamboo charcoal fibers, which is applied in the fields of fiber mixing, fiber processing, textile and paper making, etc., can solve the problems of poor elastic recovery ability, increased weight, and reduced effect of bamboo charcoal fibers and polyester.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

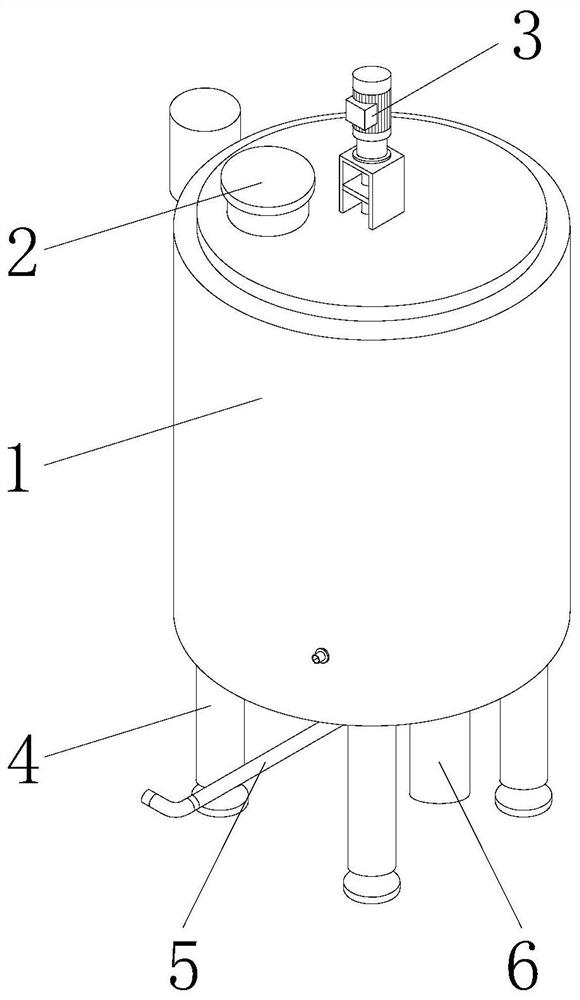

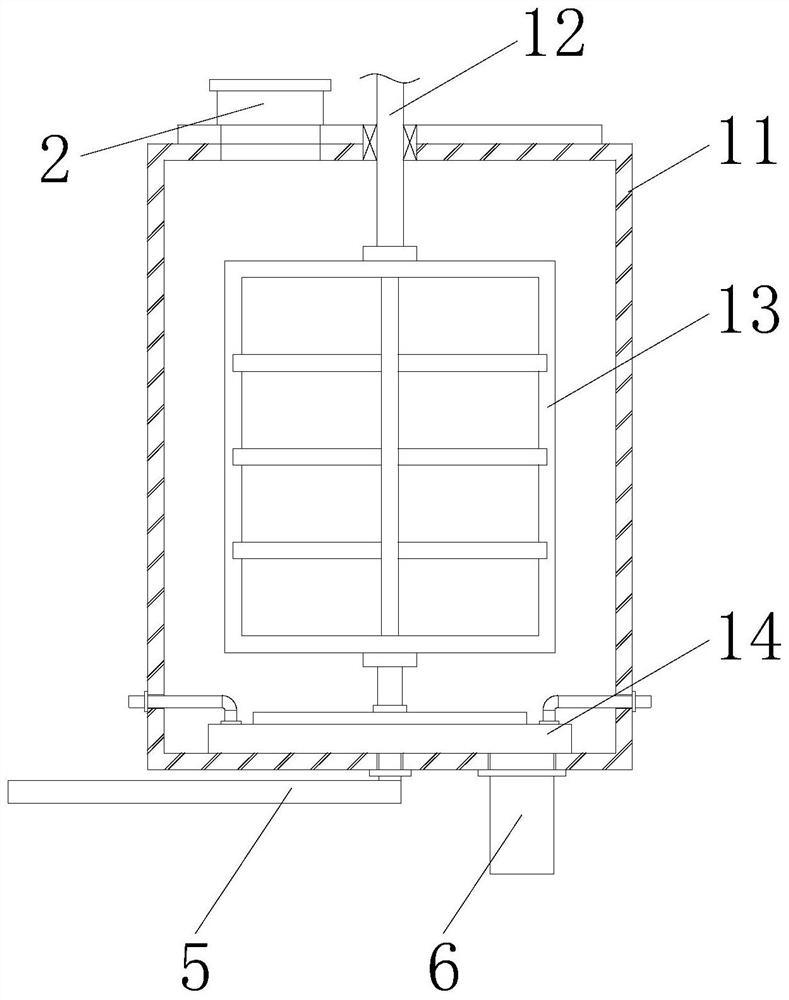

[0022] as attached figure 1 To attach Figure 4 Shown:

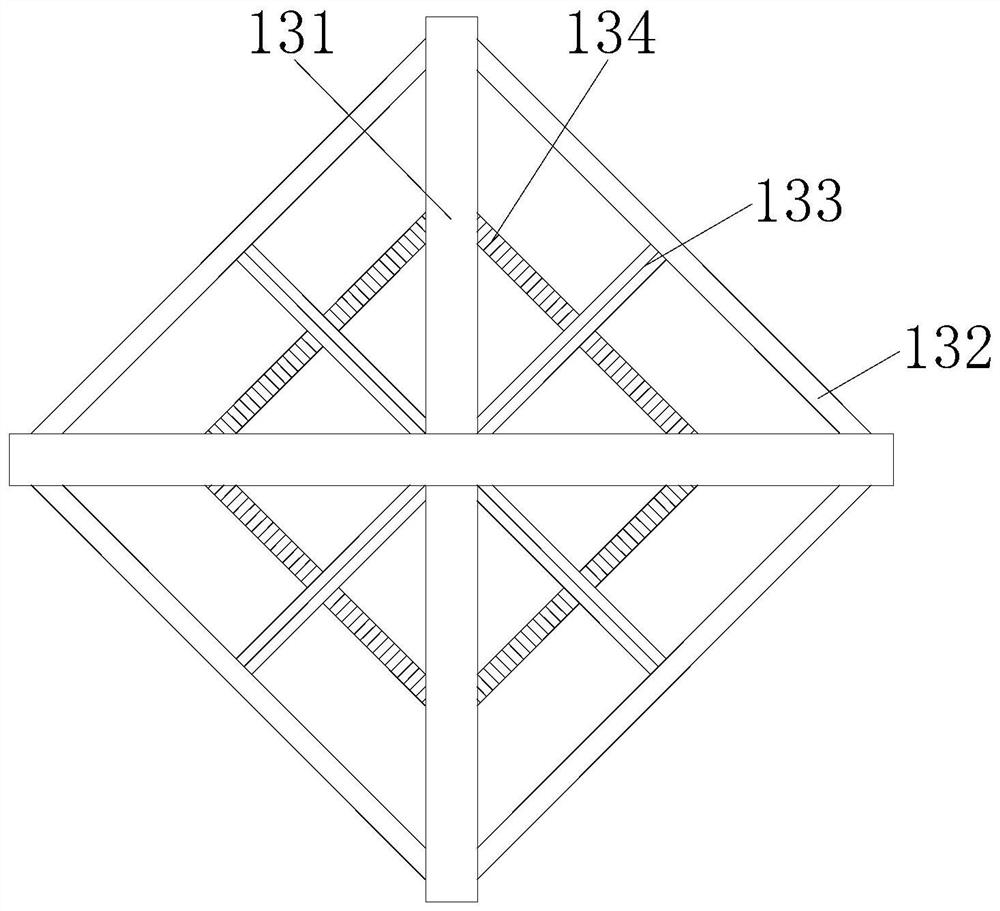

[0023] A kind of bamboo charcoal fiber polyester blended yarn mixing equipment of the present invention, its structure comprises mixing main machine 1, feed inlet 2, motor 3, support foot 4, drainage pipe 5, discharge pipe 6, described mixing main machine 1 upper end is embedded and installed There is a feed port 2 and communicates with each other, the motor 3 is installed in the middle end of the top of the mixing host 1, the upper end of the support leg 4 is welded to the bottom of the mixing host 1, the drain pipe 5 is embedded and installed in the lower end of the mixing host 1 and The discharge pipe 6 is embedded and installed in the lower end of the mixing host 1 and communicates with each other. The mixing host 1 includes a mixing box 11, a rotating rod 12, a stirring device 13, and an air injection device 14. The upper end of the mixing box 11 The feeding port 2 is embedded and connected with each other. The up...

Embodiment 2

[0029] as attached Figure 5 to attach Figure 7 Shown:

[0030] Wherein, the air injection device 14 includes a fixed seat 141, an extruding device 142, an air inlet pipe 143, and a nozzle 144. The fixed seat 141 is fixedly installed on the inner bottom of the mixing box 11, and the upper end of the fixed seat 141 is embedded with an extrusion Compression device 142, the upper end of the extrusion device 142 is welded to the lower end of the stirring outer frame 131, the outer end of the air inlet pipe 143 runs through the lower end of the mixing box 11, and the middle end of the air inlet pipe 143 is embedded and installed on the upper surface of the fixed seat 141 Inside the outside, the lower end of the air intake pipe 143 is connected to the inside of the extruding device 142, one end of the nozzle 144 is connected to the inside of the extruding device 142, and the other end of the extruding device 142 is embedded and installed on the upper surface of the fixing seat 141, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com