Polyaniline/thermoplastic polymer conductive nanofiber airgel and preparation method thereof

A technology of thermoplastic polymers and conductive nanometers, which is applied in the direction of plant fibers, fiber treatment, fiber types, etc., can solve the problems of impenetrability, high cost of graphene, and low binding force between polyaniline and cellulose, and meet the requirements of electrical conductivity Requirements, the effect of precise structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of polyaniline / thermoplastic polymer conductive nanofiber airgel, the steps are as follows:

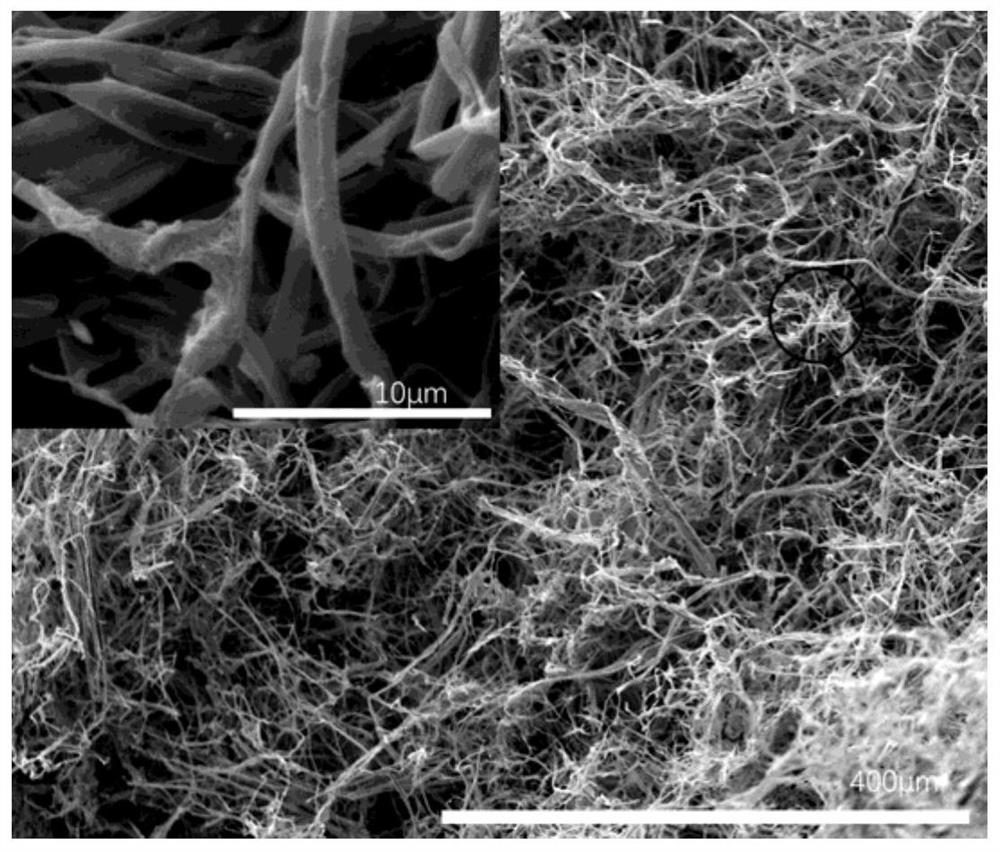

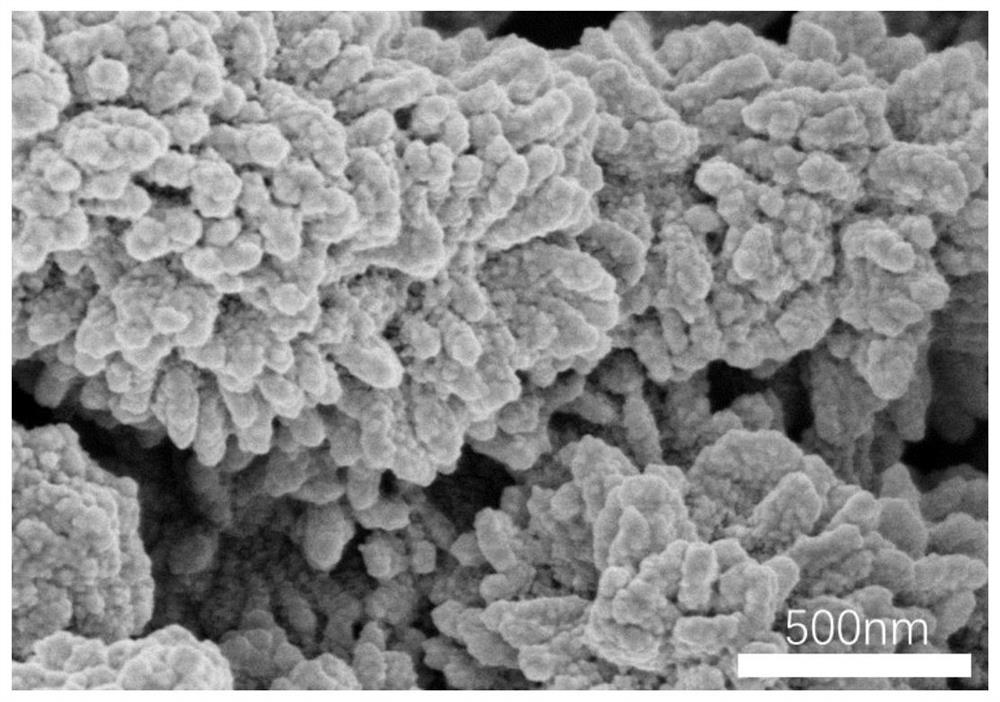

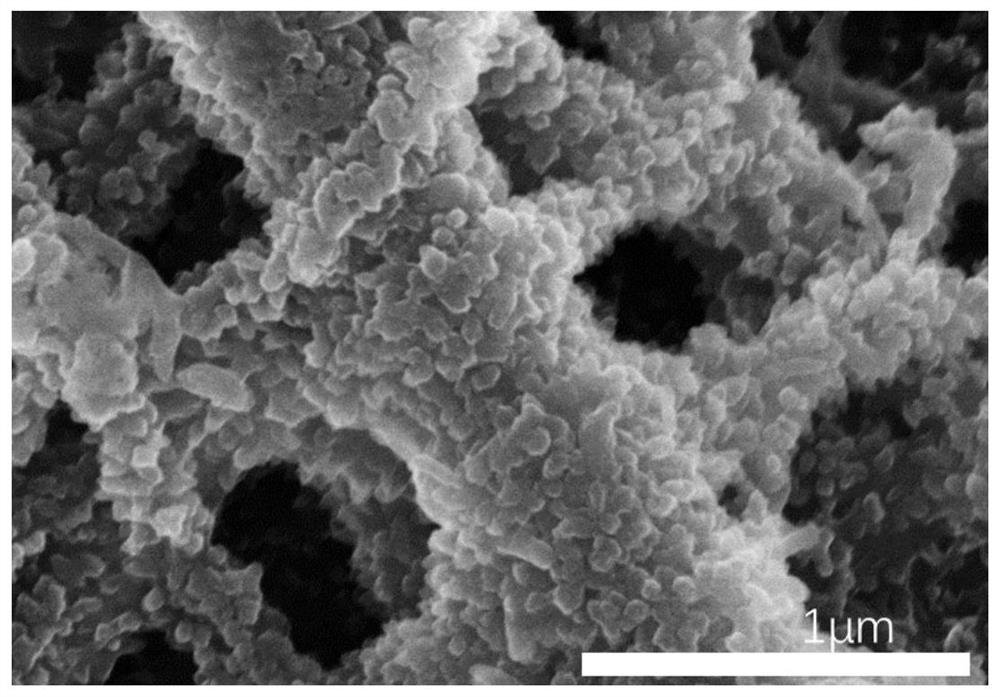

[0039] (1) Thermoplastic polymer nanofiber airgel (such as figure 1 Shown) soak in acidic solution I for 5 minutes, accompanied by ultrasonic treatment during the soaking, the frequency of ultrasonic treatment is 35 Hz, followed by soaking in aniline for 5 minutes, standing still during soaking, soaking in ethanol again for 1 second, taking out quickly after soaking, and obtaining Thermoplastic polymer nanofiber airgel with uniform adsorption of aniline on the surface and inside; the thermoplastic polymer is PBT;

[0040] Thermoplastic polymer nanofiber airgel is prepared by making nanofibers prepared by the sea-island spinning method into a suspension and then freeze-drying. The preparation process is as follows: firstly, the thermoplastic polymer and CAB (cellulose acetate butyrate) Mix uniformly according to the mass ratio of 2:8, use a twin-screw extru...

Embodiment 2

[0050] A preparation method of polyaniline / thermoplastic polymer conductive nanofiber airgel, the steps are as follows:

[0051] (1) Immerse the thermoplastic polymer nanofiber airgel in the acidic solution I for 8 minutes, accompanied by ultrasonic treatment during the infiltration, the frequency of the ultrasonic treatment is 35 Hz, followed by immersion in aniline for 6 minutes, standing when infiltrating, and infiltrating in ethanol again In 1.2s, take it out quickly after infiltration, and obtain a thermoplastic polymer nanofiber airgel with uniform adsorption of aniline on the surface and inside; the thermoplastic polymer is PBT;

[0052] Thermoplastic polymer nanofiber airgel is prepared by making nanofibers prepared by the sea-island spinning method into a suspension and then freeze-drying. The preparation process is as follows: first, the thermoplastic polymer and CAB are mixed in a mass ratio of 2:8 Mix evenly, and use a twin-screw extruder to melt and blend and extr...

Embodiment 3

[0058] A preparation method of polyaniline / thermoplastic polymer conductive nanofiber airgel, the steps are as follows:

[0059] (1) soak the thermoplastic polymer nanofiber airgel in the acidic solution I for 6 minutes, accompanied by ultrasonic treatment during the soaking, the frequency of the ultrasonic treatment is 35 Hz, then soak in aniline for 8 minutes, stand still during soaking, and soak in ethanol again In 1.5s, take it out quickly after infiltration, and obtain a thermoplastic polymer nanofiber airgel with aniline uniformly adsorbed on the surface and inside; the thermoplastic polymer is EVOH;

[0060] Thermoplastic polymer nanofiber airgel is prepared by making nanofibers prepared by the sea-island spinning method into a suspension and then freeze-drying. The preparation process is as follows: first, the thermoplastic polymer and CAB are mixed in a mass ratio of 2:8 Mix evenly, and use a twin-screw extruder to melt and blend and extrude. The temperature of the tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com