Synthetic leather adopting light and shadow treatment technology and preparation method of synthetic leather

A synthetic leather, light and shadow technology, applied in textiles and paper making, road vehicles, furniture parts, etc., can solve problems such as large investment, unenvironmental protection of chemical treatment, and environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

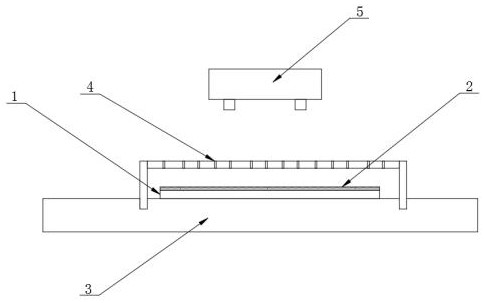

[0021] refer to figure 1 The synthetic leather of a light and shadow processing technology shown includes a light and shadow leather finished product 1, the top of the light and shadow leather finished product 1 is provided with a light-touching surface 2, and the light and shadow leather finished product 1 and the light-touching surface 2 are integrated. The bottom of the finished leather product 1 is provided with a transmission panel 3, the top of the finished leather product 1 is provided with a shading plate 4, the inside of the shading plate 4 is uniformly provided with light holes, and the top of the shading plate 4 is provided with an infrared emitter 5.

[0022] One side of the shading plate 4 is provided with an atomization heating mechanism, and the other side of the shading plate 4 is provided with a leveling mechanism, and the atomization heating mechanism and the leveling mechanism are used for heating and leveling the surface of the light-touching surface 2. wor...

Embodiment 2

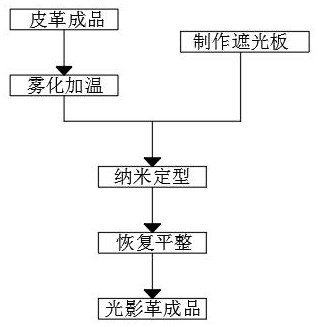

[0026] refer to figure 2 Shown is a method for preparing synthetic leather with light and shadow processing technology, and the specific preparation steps are:

[0027] Step 1: According to the desired pattern on the surface of the light-touching surface 2, use different light-shielding plates 4, and adjust and process the arrangement of the internal through holes by a computer, so that various pattern effects can be realized through the through holes;

[0028] Step 2: Place the light and shadow leather finished product 1 on the surface of the transmission panel 3 and move it. During the process of moving and transmitting, the atomization heating mechanism atomizes and heats the surface of the light-touching surface 2. After moving to the bottom of the light-shielding plate 4, the infrared emitter 5 The work emits light waves, causing gloss changes on the surface of the light-touching surface 2;

[0029] Step 3: After the surface of the light-touching surface 2 realizes the ...

Embodiment 3

[0031] serial number Leather thickness (mm) temperature (°C) Photomask Nano Module Specifications (nm) Infrared light wavelength (μm) Light speed (m min) 1 1.2 91.5 215 150 14.5 2 1.0 81.5 490 240 11.5

[0032] Obtain polyurethane microfiber leather for automotive interiors, use the post-treatment production line of light and shadow leather to prepare automotive microfiber light and shadow leather, and obtain sample 1, obtain polyurethane PU leather for home decoration soft bags, and use light and shadow leather post-processing production line to prepare PU light and shadow leather for home decoration, and obtain sample 2, The prepared samples 1 and 2 can meet the individual design requirements for the appearance of the car interior. The pattern forms vary with the complexity, light intensity and production speed, but the impact on the cost is not obvious.

[0033] To sum up, the light and shadow processing technology synthetic leather ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Smallest size | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com