A wire-passing drive shaft assembly and wire-passing method

A transmission shaft and assembly technology, applied in the field of wire-passing tools and wire-passing methods, can solve the problems of unstable transmission, easy disconnection of lines, and difficulty in fixing lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

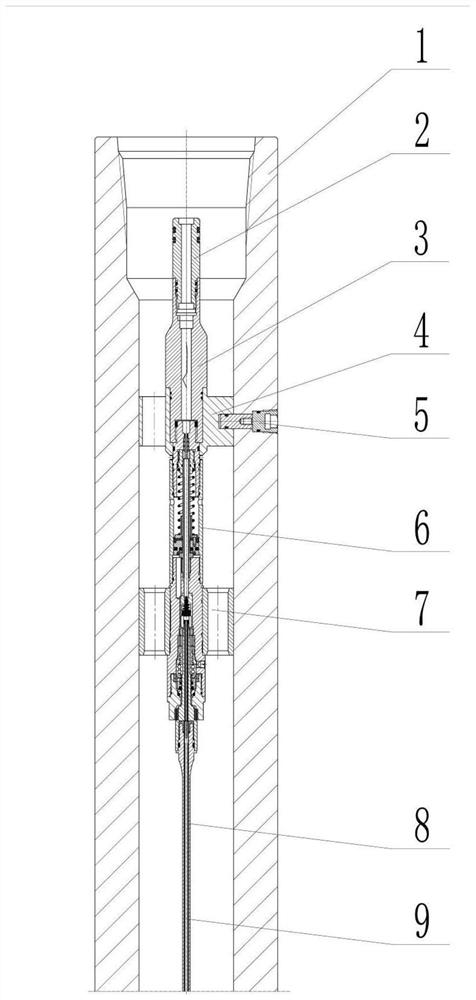

[0036] This embodiment first provides a slip ring connection assembly, the structure of which is as follows figure 1 shown.

[0037] The slip ring connection assembly includes a slip ring assembly outer shell 1, a socket joint 2, a transition positioning joint 3, a slip ring assembly positioning centralizer 4, a positioning pin 5, a slip ring assembly 6, a slip ring centralizer 7, Flexible shaft 8, conductive rod 9, figure 1 The formed slip ring assembly can convert the rotating wire in the rotor 21 and the flexible shaft 8 into a fixed wire connection.

[0038] The slip ring connection assembly includes a slip ring assembly outer casing 1, which is provided with a transition positioning joint 3 and a slip ring assembly 7 fixed by the slip ring assembly positioning centralizer 4 and the slip ring centralizer 7 respectively. , the lower end of the slip ring assembly 7 is provided with a flexible shaft 8 , and a flexible shaft conductive rod 9 is arranged in the flexible shaft...

Embodiment 2

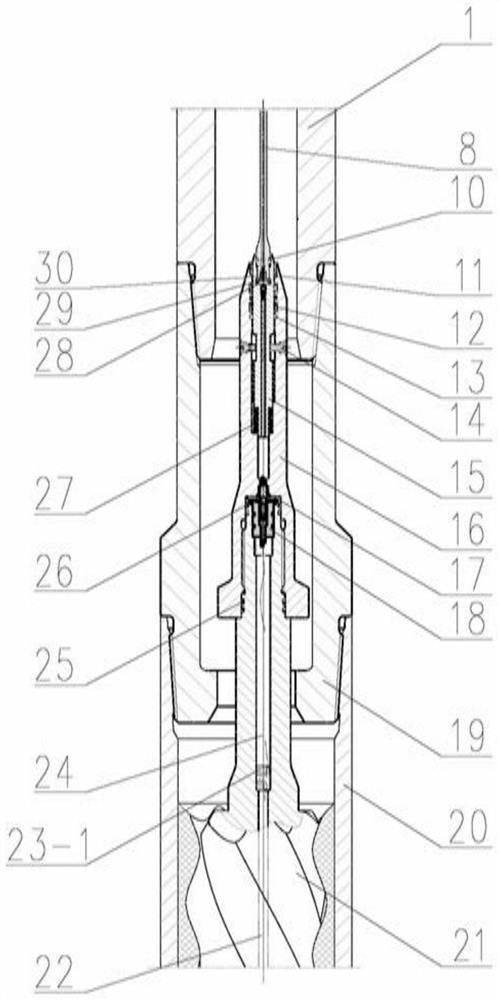

[0040] In the existing various wire motor technologies, some methods and devices for screw wire connection communication use slip ring connection structure, and some use wireless coupling communication. Affected by the vibration of the tool and the change of the axial position of the rotor when the screw is working in the downhole, the slip ring structure has the problems that the seal is difficult to guarantee and the contact quality is poor. The wireless coupling transmission method has the problems of poor reliability and low transmission efficiency. In view of these problems, this embodiment provides a wire-passing motor assembly, the structure of which is as follows figure 2 shown.

[0041] The function of the wire-passing motor assembly is to eliminate the axial vibration or floating generated by the motor rotor 21, so as to ensure that the central wire passing through the wire is connected, and the wire is not torn off.

[0042] The wire-passing motor assembly include...

Embodiment 3

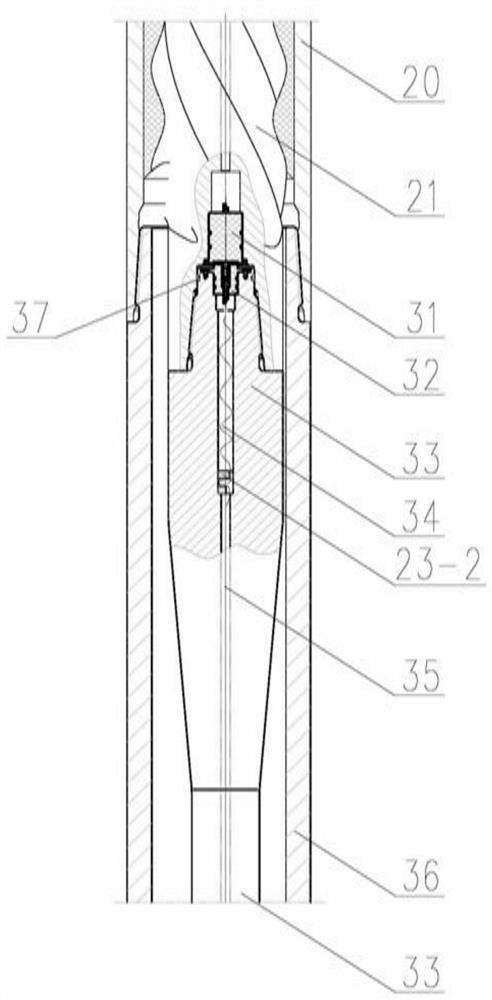

[0054] The wire-passing universal shaft in the prior art has unstable fixation of the main line, poor anti-vibration capability of the line, and poor contact of the conductive plug and socket, resulting in problems such as large line transmission resistance, line heating, and unstable connection.

[0055] In view of these problems, this embodiment provides a wire-passing universal joint shaft assembly, the structure of which is as follows Figure 3-4 shown. The wire-passing universal shaft assembly includes: conductive pins 31 under the rotor, conductive sockets 32 on the flexible shaft, power flexible shaft 33, power flexible shaft center wire 34, flexible shaft winding seat 23-2, power flexible shaft wire 35. The flexible shaft outer casing 36, the flexible shaft sealing ring 37, the conductive pins 31 under the rotor, the lower sealing ring 38 of the flexible shaft, the conductive pins 39 under the flexible shaft, the rotating shaft transition socket 40, the transmission sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com