Radial plunger pump

A technology of radial column and plug pumps, which is applied in the direction of pumps, multi-cylinder pumps, liquid displacement machines, etc. It can solve the problems of leakage, increased flow distribution gap, large bending deformation of oil distribution shaft, etc., and reduce wear , The effect of improving the problem of bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

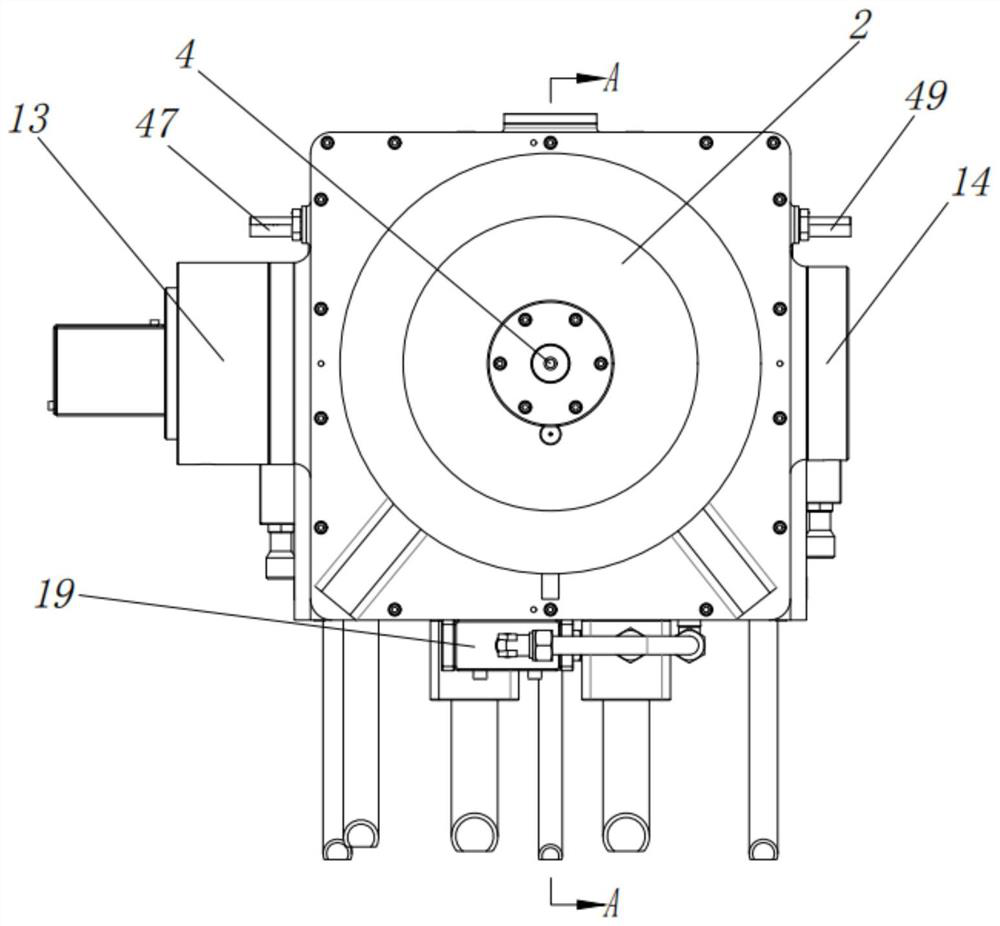

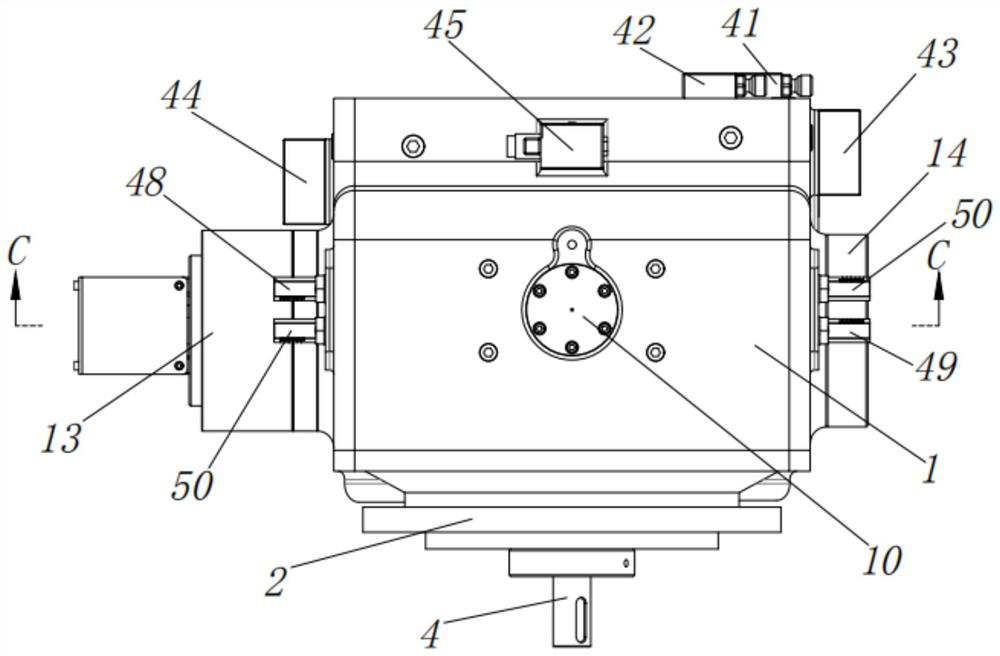

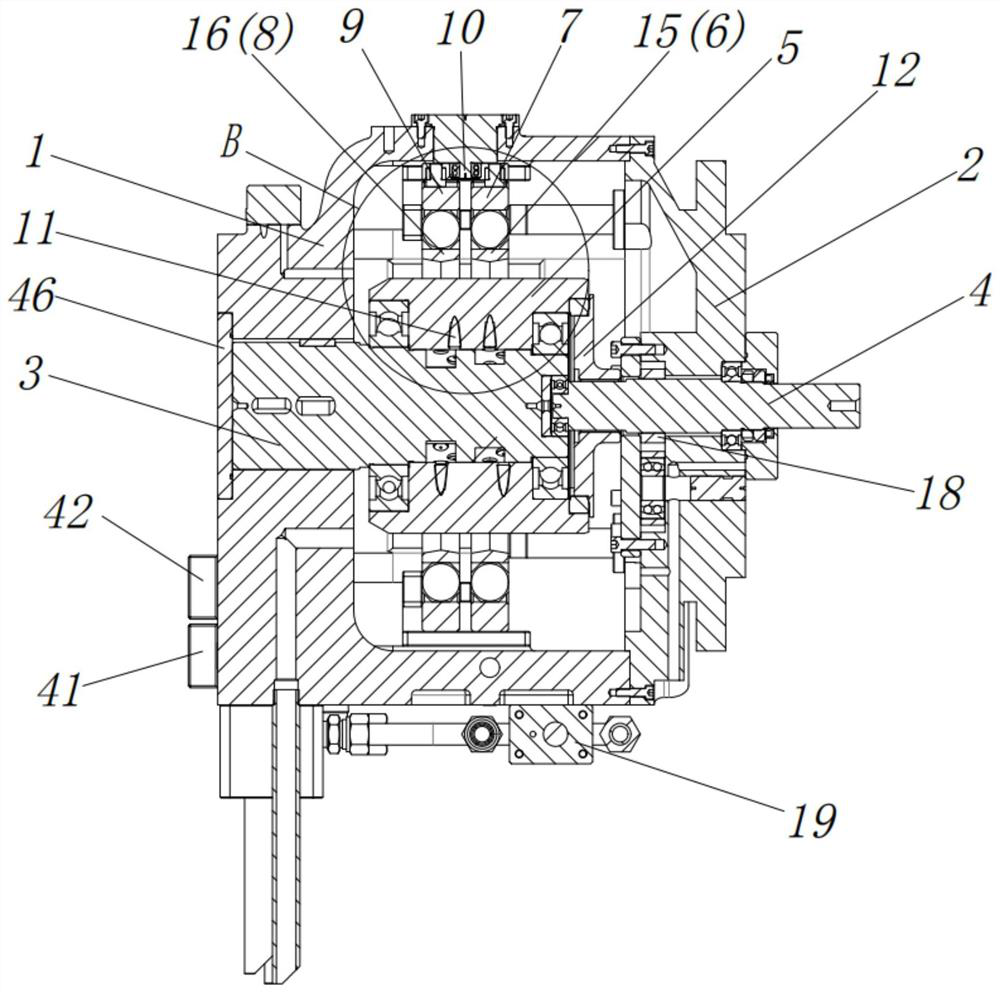

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] Figure 1 to Figure 17 An embodiment of the radial piston pump of the present invention is shown. The radial piston pump of this embodiment includes a housing 1, an oil distribution shaft 3, a rotor 5, and a transmission shaft 4 for driving the rotor 5 to rotate. It also includes a stator assembly 15 sleeved on the outer periphery of the rotor 5, and a sliding seat assembly 16 for adjusting the eccentricity between the stator assembly 15 and the rotor 5, the oil distribution shaft 3 is arranged in the housing 1, and the The transmission shaft 4 is arranged on the housing 1, and the oil distribution shaft 3 is provided with a first oil distribution window 31 and a second oil distribution window 32 for balancing the radial force on the oil distribution shaft 3 , the rotor 5 is provided with a plurality of plungers 11 correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com