Current-conducting plate with electricity taken from bottom, track lamp and production method of current-conducting plate

A technology of conductive plates and tracks, applied in the direction of electrical components, printed circuits, circuit layout, etc., can solve the problems of short circuit, affecting the light source and iron plate magnetism, etc., and achieve the effect of reducing resistance, simple structure, and enhanced magnetic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

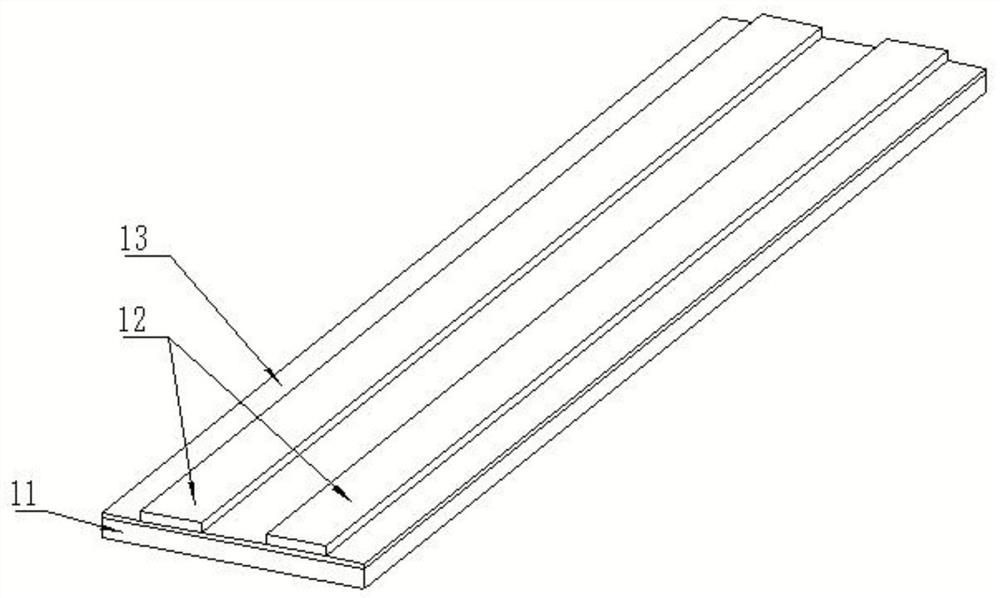

[0048] Such as figure 1The shown conductive plate 1 for taking electricity from the bottom includes a substrate 11 and a conductive strip 12 made of magnetic materials. The substrate 11 can be an iron plate, or other plates that can generate magnetic attraction with a magnet. The upper surface of the substrate 11 is one side, and the lower surface is the other side. When installing the conductive plate 1, the direction of inserting it into the track is the length direction of the substrate 11; the material of the conductive strip 12 is copper or copper alloy. The thickness of the conductive strips 12 is 0.035-0.35mm, the number of the conductive strips 12 can be two or three and there is a gap between two adjacent conductive strips 12, the number of the conductive strips 12 on each side is It is determined according to whether the light source 5 uses direct current or alternating current. A first insulating layer 13 with a thickness of 0.15-0.3 mm is bonded between the substr...

Embodiment 2

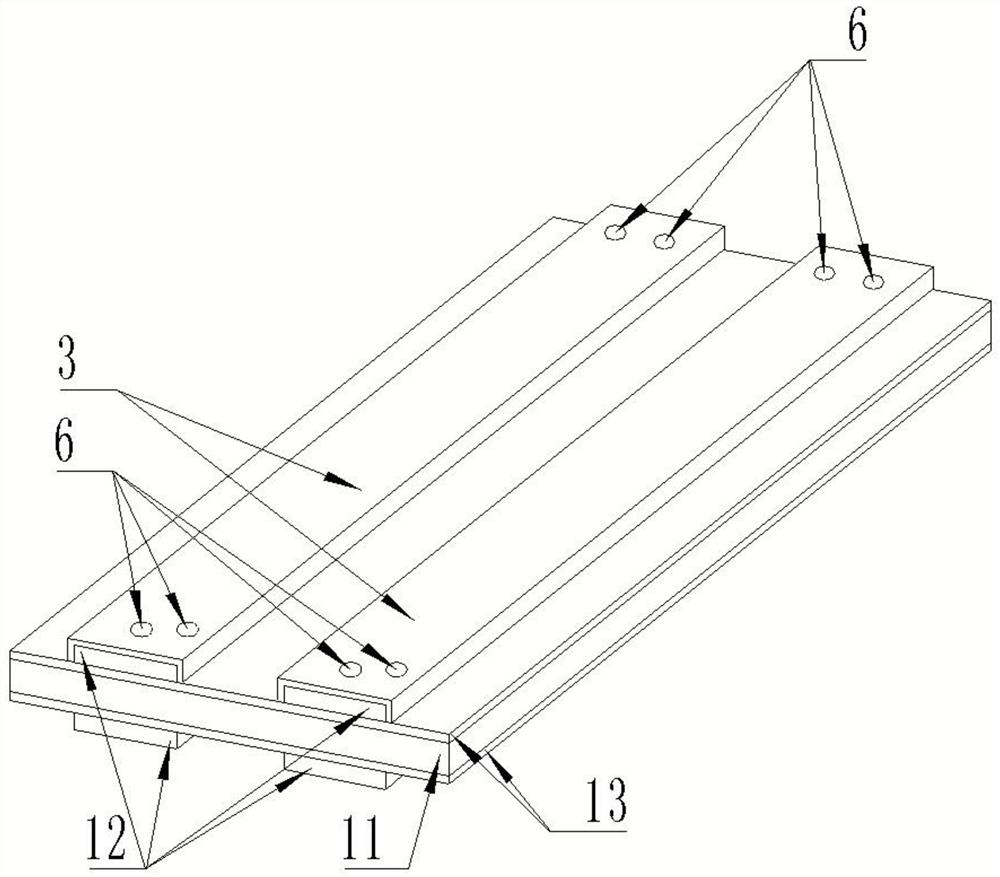

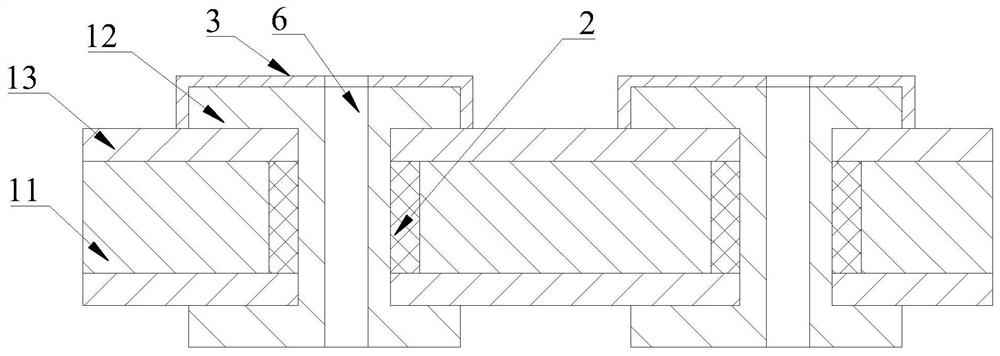

[0050] Such as figure 2 and image 3 A conductive plate 1 that takes power from the bottom is shown, and only part of its length is shown in the figure, including a substrate 11 made of magnetic material, a first insulating layer 13 and a conductive strip 12. The substrate 11 can be an iron plate, Also can be other plates that can generate magnetic attraction with magnets, the upper surface of the substrate 11 is one side, and the lower surface is the other side; The first insulating layer 13 can be a prepreg with a thickness of 0.15-0.3mm, the first insulating layer 13 is bonded to the upper and lower surfaces of the substrate 11 by pressing, and the conductive strip 12 is made of copper or copper alloy material , the conductive strips 12 are bonded to the surface of the first insulating layer 13 on the upper and lower surfaces of the substrate 11 by pressing and extend along the length direction of the substrate 11; the number of conductive strips 12 on the upper and lower...

Embodiment 3

[0052] A track 4 light such as Figure 4 As shown, it includes a light source 5 connected to a plurality of rails 4. The figure only shows the situation that two rails 4 are connected. The lower part of the inner surface is slidably connected with the conductive plate 1 for taking electricity from the bottom provided by the technical solution in embodiment 2, and the conductive surface of the conductive plate 1 faces upward; The chute 7, the light source 5 slides in the chute 7; the conductive strip 12 on the conductive plate 1 is electrically connected with the light source 5 and provides power for the normal operation of the light source 5; a magnet is arranged in the light source 5, and the magnet The substrate of the conductive plate 1 generates magnetic force and attracts each other, and the magnetic force makes the light source 5 contact with the conductive plate 1 and maintain good electrical connection; the front and rear ends of the pad surface of the conductive plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com