Full-premixing plate type steam generator

A steam generator and fully premixed technology, which is applied in the direction of steam generation, steam generation method using pressure combustion, steam boiler, etc., can solve the problems of inconsistent intensity, uneven flame distribution, low thermal efficiency, etc., and achieve consistent combustion intensity, The effect of uniform flame distribution and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

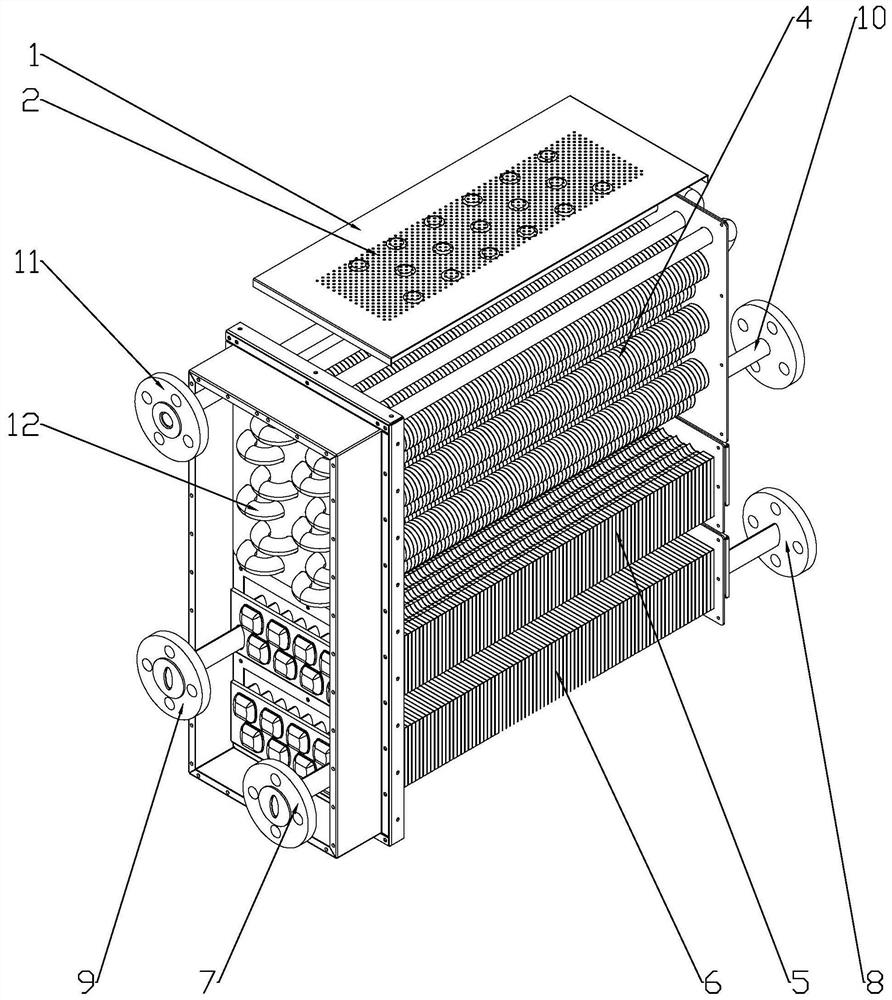

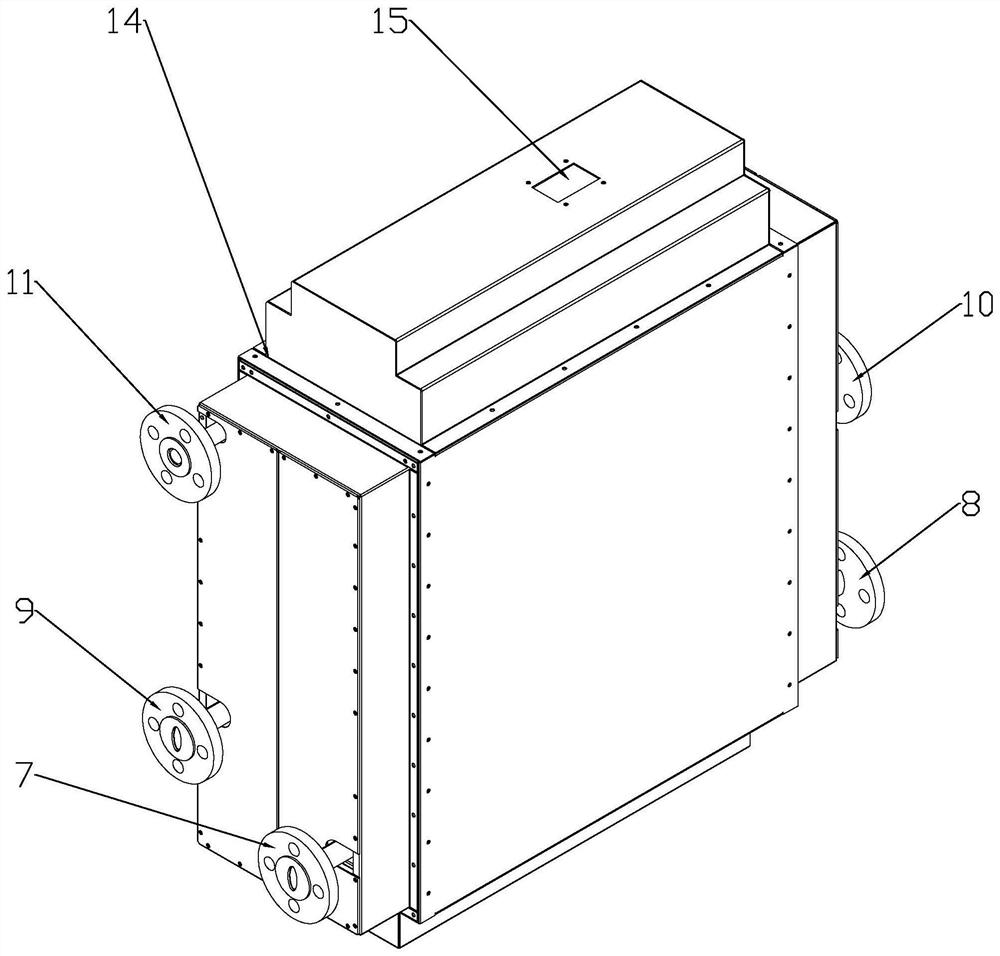

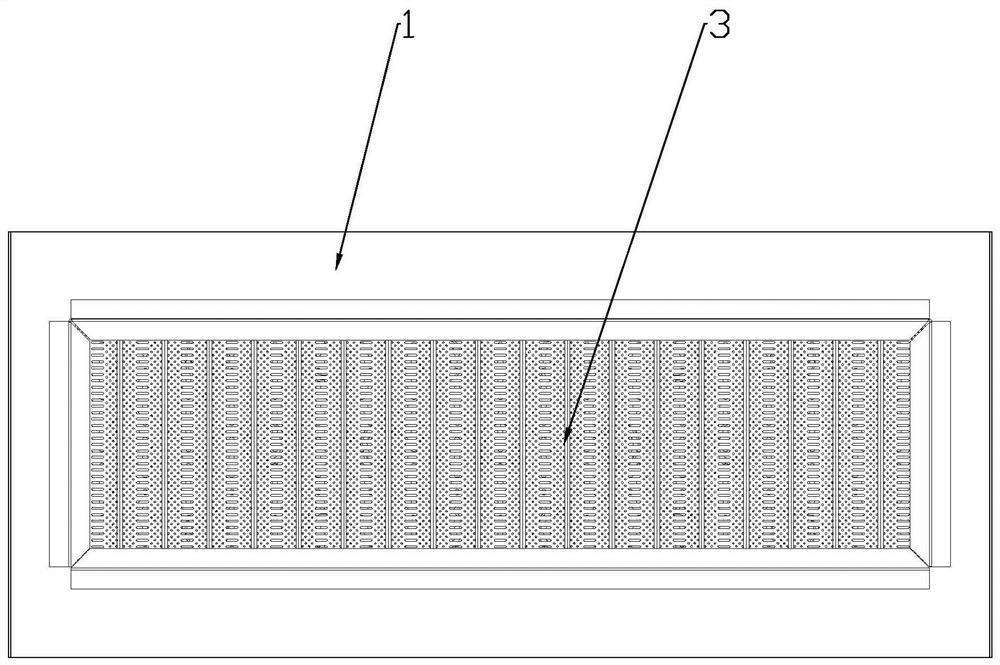

[0021] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a fully premixed plate steam generator includes a main casing 14 , a burner, a vaporization section 4 , a heating section 5 and a preheating section 6 .

[0022] The top of the main housing 14 is provided with a gas inlet 15, the bottom of the main housing 14 is provided with a flue gas outlet 16, and the interior of the main housing 14 is sequentially provided with a burner, a vaporization section 4, and a heating section 5 from top to bottom. , the preheating section 6, the upper end of the vaporization section 4 communicates with the steam outlet 11, the water inlet 13 of the vaporization section communicates with the water outlet 10 of the heating section through a pipeline, the water inlet 9 of the heating section communicates with the water outlet 7 of the preheating section, and the water inlet 13 of the heating section communicates with the water outlet 7 of the preheating section. The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap