Mobile phone glass panel drying facility

A technology of glass panels and drying facilities, applied in the direction of drying solid materials, dry goods handling, dry gas arrangement, etc., can solve the problems of leaving traces, increasing production costs, wasting electricity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

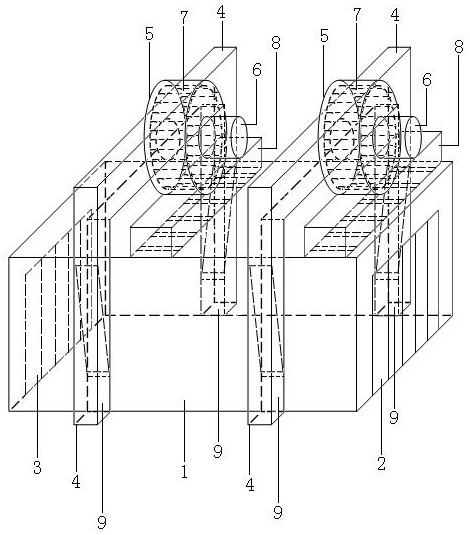

[0015] Now describe in detail the shape and structure of the present invention in conjunction with accompanying drawings and reference numerals:

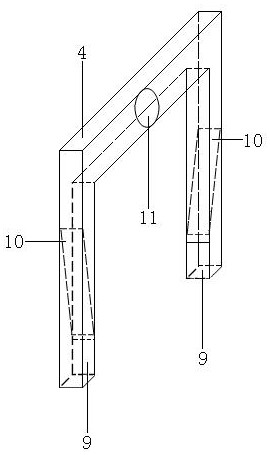

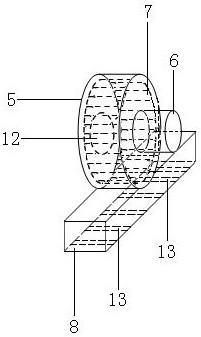

[0016] A mobile phone glass panel drying facility, characterized by comprising a body 1, a material inlet door 2, a material outlet door 3, an exhaust pipe 4, a centrifugal fan (>15m³ / min) 5, a high-speed motor (AC380V / 3-7kw) 6 , centrifugal fan 7, air supply pipe 8, air outlet 9, filter screen 10, air outlet 11, air inlet 12, nozzle 13, power switch (AC400V / 80A) 14, power cord (4x6mm²) 15;

[0017] The body is hollow and rectangular, the left side is provided with a rectangular discharge door, and the top of the discharge door is provided with a strip-shaped leather curtain downwards, and the right side is provided with a rectangular feed door and the top of the feed door. A strip-shaped leather curtain is set downward;

[0018] A hollow rectangular air supply pipe is arranged vertically on the left and right sides above the body,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap