A method for detecting adhesion and burrs on the surface of stamping workpieces

A stamping workpiece and detection method technology, which is applied in the field of stamping workpiece burr detection, can solve the problems of small adhesion marks, inconspicuousness, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

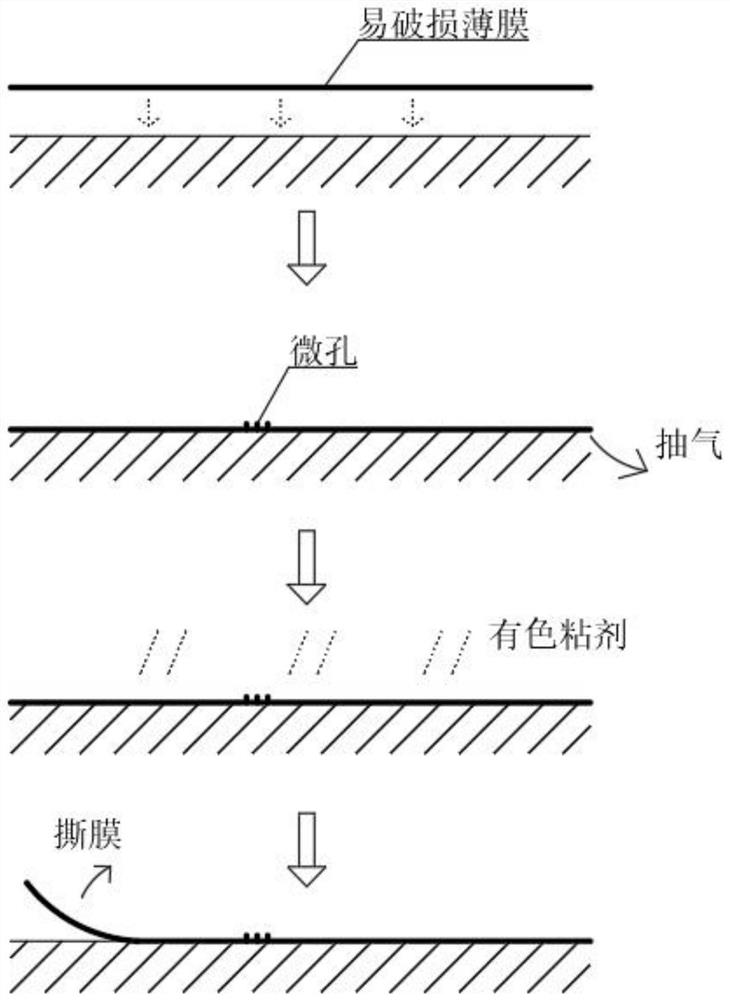

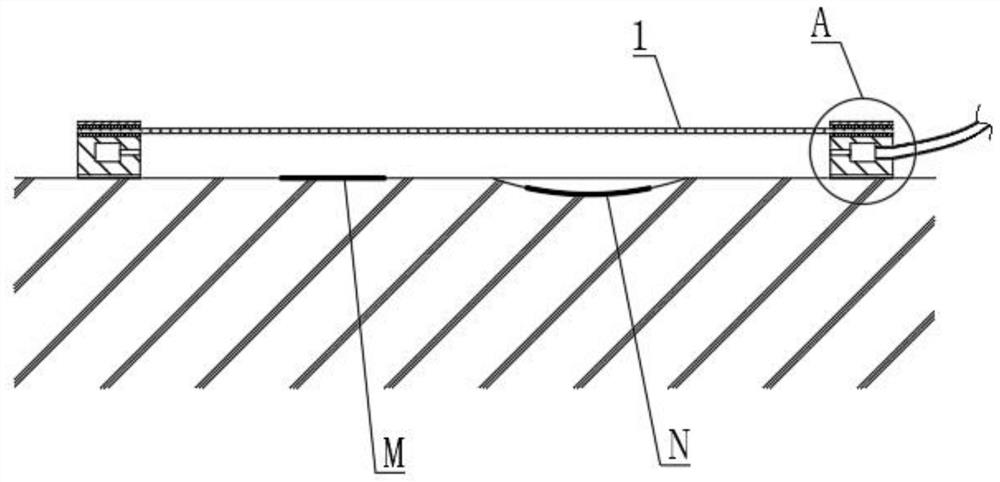

[0052] see figure 1 , a method for detecting adhesion burrs on the surface of stamping workpieces, comprising the following steps:

[0053] S1. Film: Clean and dry the surface of the workpiece after stamping, and paste the fragile film around the area to be detected on the surface of the workpiece, covering the entire area to be detected;

[0054] S2. Air pumping and membrane rupture: connect the fragile film to the suction pump, start the suction pump, and extract the gas between the fragile film and the workpiece. Under the action of vacuum pressure, the fragile film gradually adheres closely to the surface of the workpiece to be detected , causing the adhesion burrs to pierce the fragile film to form micropores, and the vacuum state is continuously maintained between the fragile film and the workpiece;

[0055] S3. Spray liquid coagulation: evenly spray a sufficient amount of colored adhesive on the outer surface of the easily damaged film, so that the colored adhesive com...

Embodiment 2

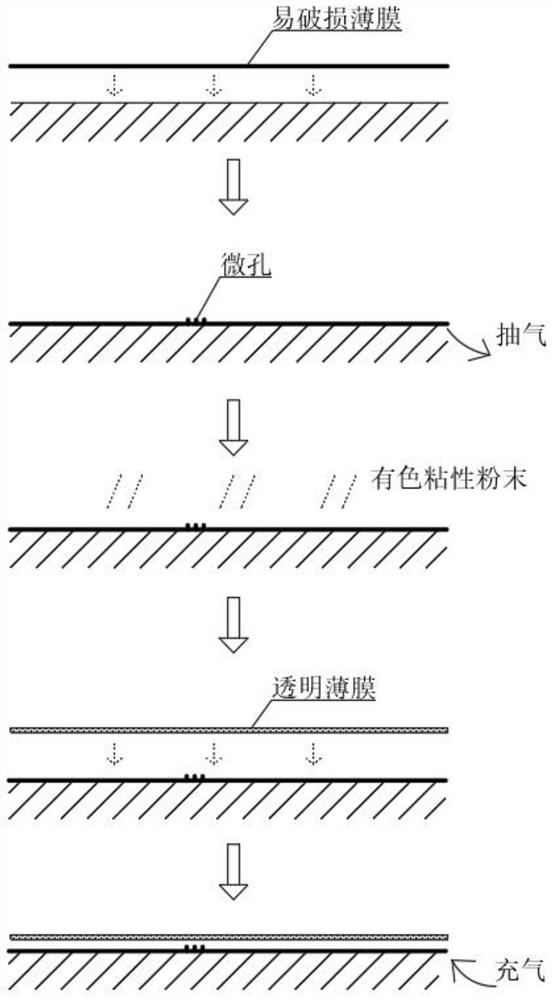

[0061] see figure 2 , a method for detecting adhesion burrs on the surface of stamping workpieces, comprising the following steps:

[0062] A1. Film: Clean and dry the surface of the workpiece after stamping, and paste the fragile film around the area to be detected on the surface of the workpiece, covering the entire area to be detected;

[0063] A2. Air pumping and membrane rupture: connect the fragile film to the suction pump, start the suction pump, and extract the gas between the fragile film and the workpiece. Under the action of vacuum pressure, the fragile film gradually adheres closely to the surface of the workpiece to be detected. , causing the adhesion burrs to pierce the fragile film to form micropores, and the vacuum state is continuously maintained between the fragile film and the workpiece;

[0064] A3. Powder coating: evenly spray a layer of colored sticky powder on the outer surface of the easily damaged film, and then cover the outer surface of the easily ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com