Stable temperature compensation measurement method for guided wave radar liquid level meter

A guided wave radar and temperature compensation technology, applied in the field of instrument calibration, can solve problems such as measurement liquid level fluctuations and measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] The guided wave radar level gauge is a level sensor with a coaxial measuring probe for continuous level and separation layer measurement in liquids at temperatures up to 450°C. The measurement principle is as follows: High-frequency microwave pulses run along a steel cable or rod, and are reflected back after touching the surface of the medium. After the microwave running time is analyzed and processed by the instrument, the liquid level value is output.

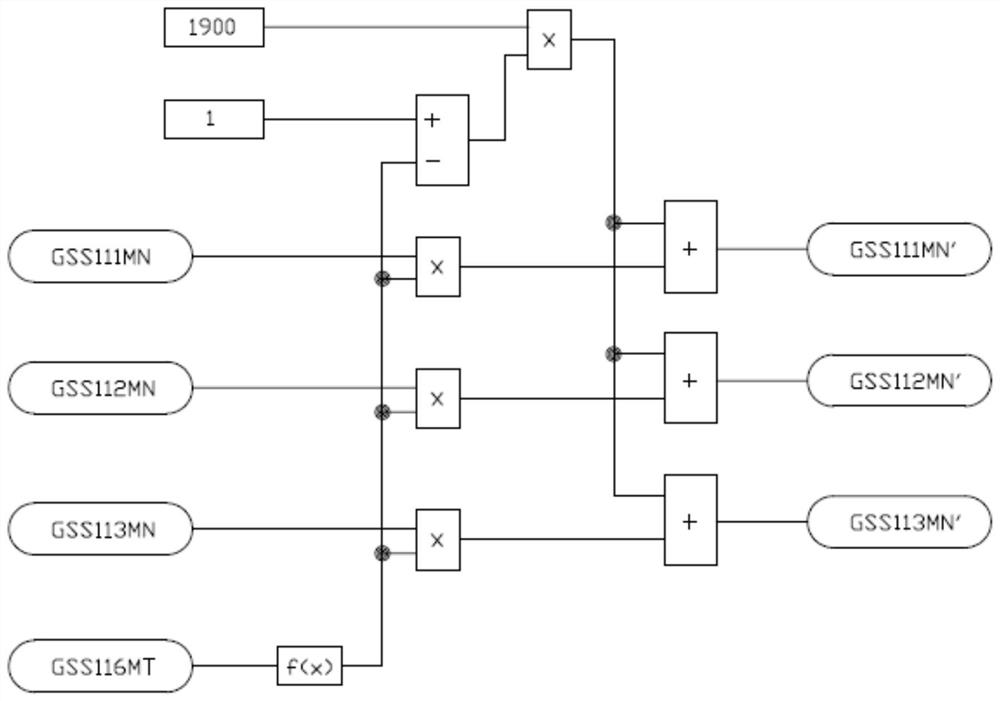

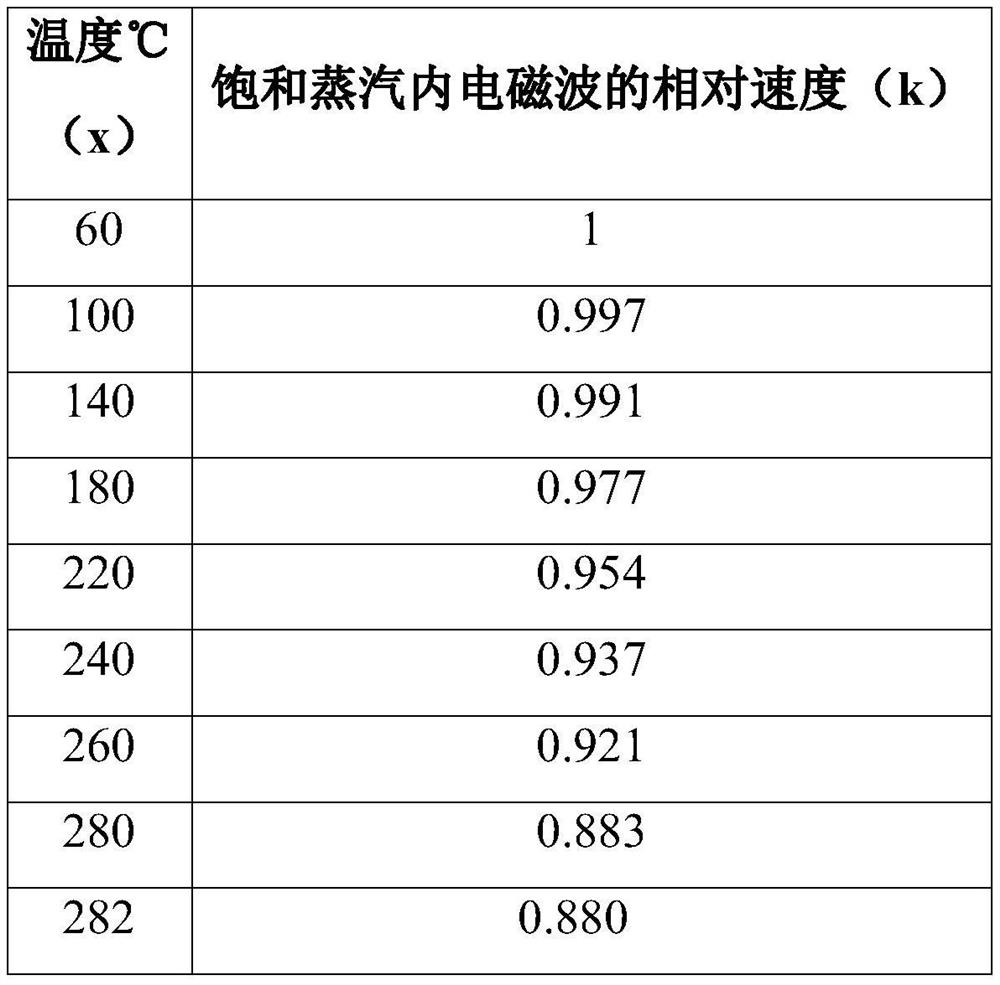

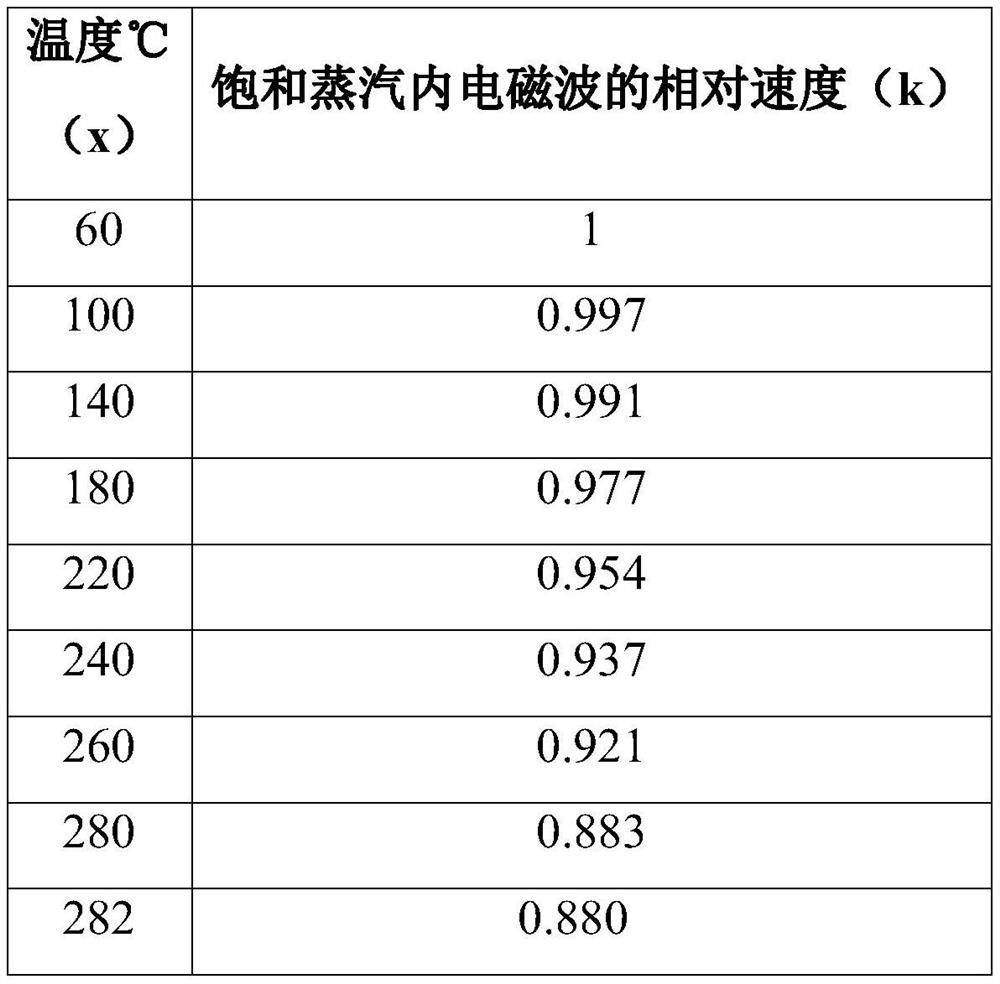

[0031] The reason and principle of automatic steam compensation for guided wave radar level gauge: The propagation speed of electromagnetic wave pulses in different media is different. Because the steam in the tank will affect the speed of electromagnetic waves during the measurement process, it is necessary to calculate the influence of steam on the propagation speed , and finally g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com