Feeding device

A technology of feeding device and distributor, applied in packaging, transportation and packaging, transportation of passenger cars, etc., can solve the problems of uneven feeding, easy material blockage, equipment damage, etc., to avoid material level fluctuations and improve equipment. Effectiveness of operating rate and productivity, ensuring safe and continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

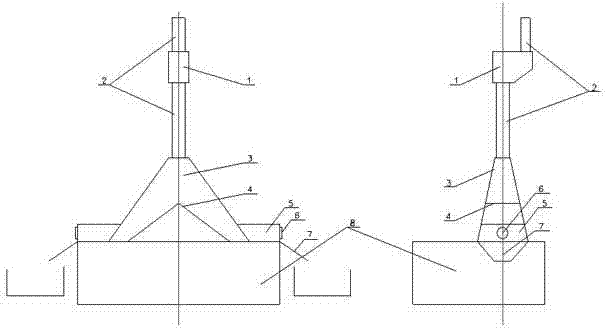

[0017] Such as figure 1 A kind of feeding device of the present invention shown is made up of following structure: feeder 3, is provided with buffer bucket 1 above feeder 3, feeder 3 is connected with buffer bucket 1 through intermediate straight slide 2, feeder The bottom of 3 is connected to the preheating screw 8, and a self-draining channel 5 is provided on the outside of the feeder 3 above the preheating screw 8, and a grid sieve 4 is provided at the bottom of the center of the feeder 3. The middle straight slide 2 is connected with the bottom of one side of the buffer bucket 1, and the top of the other side of the buffer bucket 1 is connected with the blanking straight slide 2. The bottom of one side buffer bucket 1 is a slope. The two narrow surfaces of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com