Method for testing reliability of electro-hydraulic-magnetic-hybrid-loaded servo power tool rest

A dynamic tool holder and hybrid loading technology, which is used in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems of poor load simulation effect, high loading cost of power head, and only torque can be applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

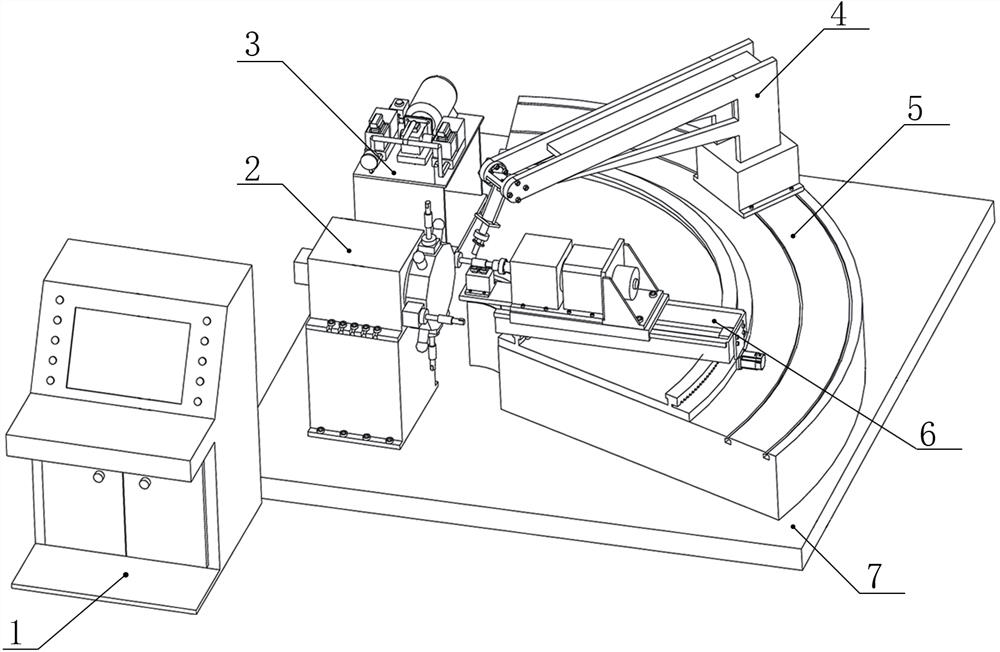

[0078] Example 1 Electro-hydraulic-magnetic hybrid loaded servo power tool holder reliability test platform

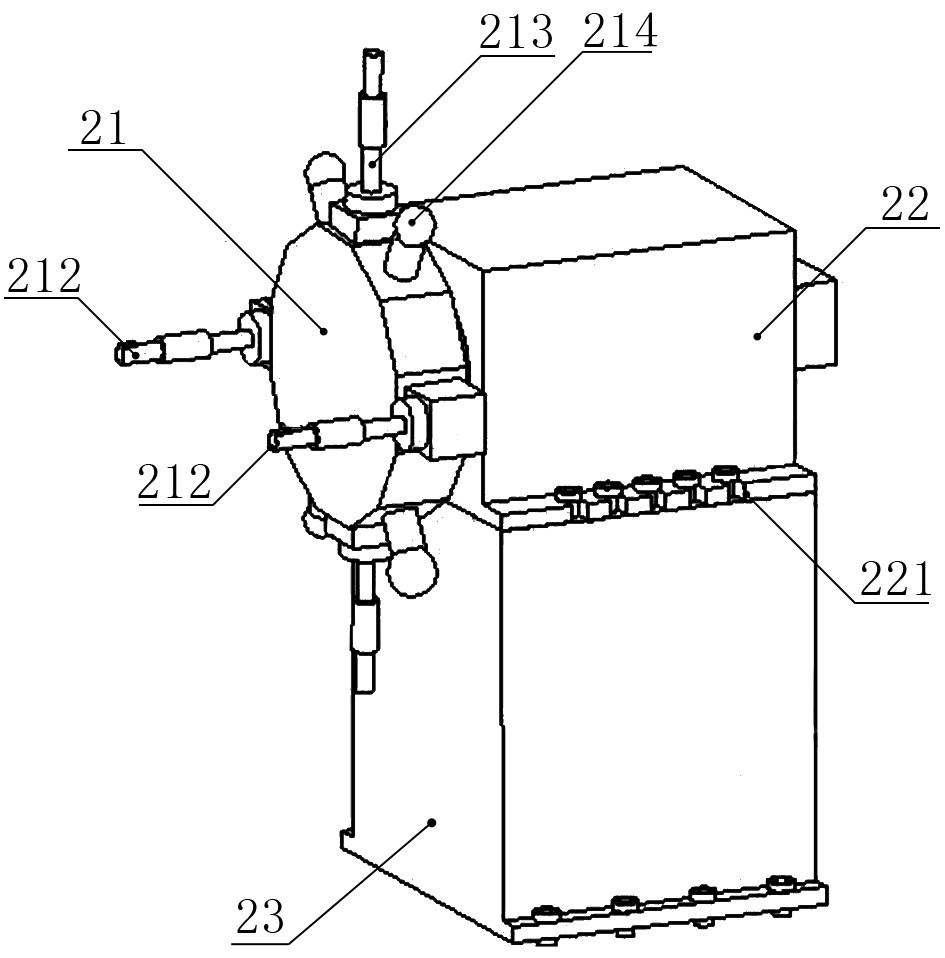

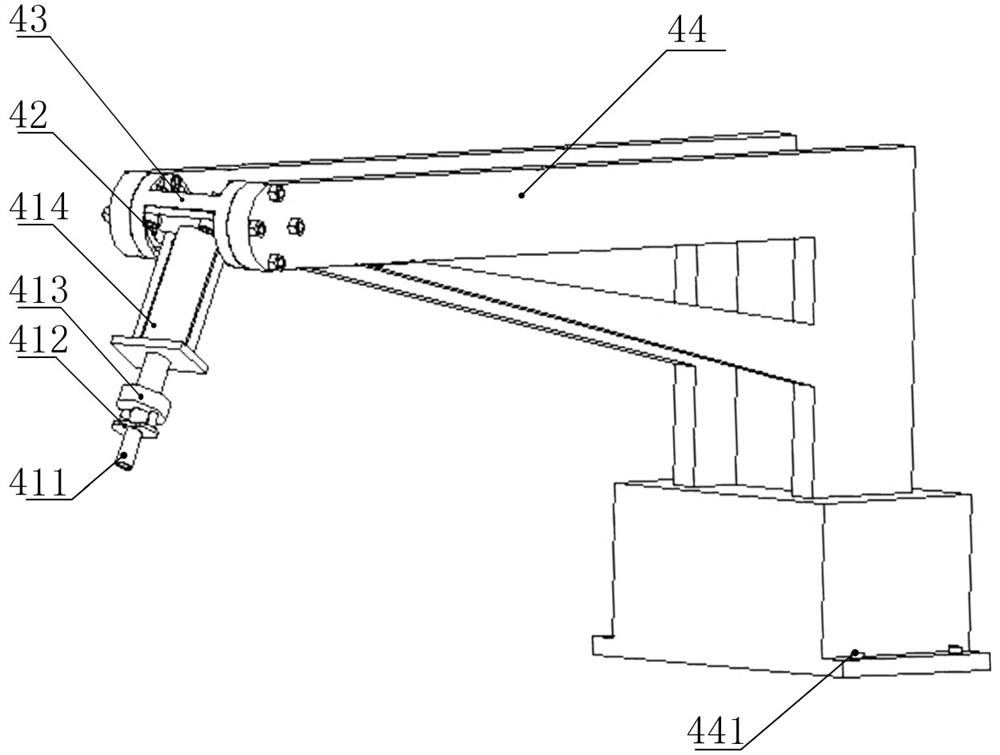

[0079] Electro-hydraulic-magnetic hybrid loading servo power tool post reliability test platform, which includes: console 1, tool post 2, hydraulic system 3, common tool head loading system 4, loading system base 5, power head loading system 6;

[0080] The console 1 is provided with a signal connection end, and the signal connection end is respectively connected with the tool rest 2, the hydraulic system 3, the force sensor 413 in the common cutter head loading system 4, and the electric dynamometer 65 in the power head loading system 6. , the force detection coil 612, and the displacement sensor 614 are electrically connected; the loading process of the tool holder is controlled through the console 1, and the load loading is detected;

[0081] The common cutter head loading system 4 and the power head loading system 6 are installed on the loading system base 5; the t...

Embodiment 2

[0118] Embodiment 2 Electro-hydraulic-magnetic hybrid loading servo power tool post reliability testing method

[0119] refer to Figure 9 , Figure 10 The reliability test method of the servo-powered tool post with electro-hydraulic-magnetic hybrid loading mainly includes the servo-powered tool post indexing test, the servo-powered tool post ordinary tool head loading test, the servo-powered tool post 90° loading test and the servo-powered tool post 180° loading test Test, method steps are as follows:

[0120] 1. Indexing test of the power servo tool post;

[0121] 1) Keep the test temperature constant at 23°C, and place the test bench in the test environment for more than 8 hours;

[0122] 2) Ensure that the ordinary cutter head loading system 4 and the power head loading system 6 are in a separated state;

[0123] 3) Make sure that the hydraulic system 3 is in normal working condition;

[0124] 4) Select servo powered tool post indexing test on console 1;

[0125] 5) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com