Perovskite film morphology structure detection method based on digital holography

A technology of digital holography and detection method, which is applied to measurement devices, material analysis by optical means, instruments, etc., can solve the problem of high cost, and achieve the effect of low cost, low test condition requirements and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

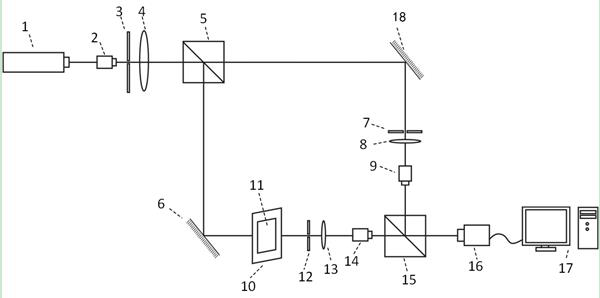

[0021] A method for detecting the morphology and structure of perovskite films based on digital holography, the optical path diagram is as follows figure 1 As shown, the specific steps are as follows:

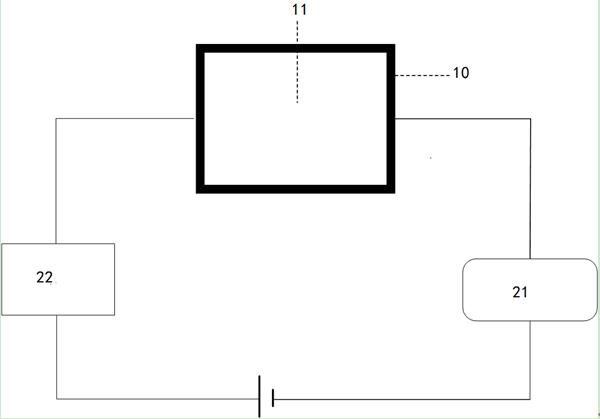

[0022] (1) The light emitted by the laser 1 is expanded and collimated through the first collimation system (objective lens I2, pinhole I3, collimator lens I4), and the parallel light is divided into two beams by the beam splitter 5, one beam is the object One beam of light O is the reference light R; the object light O is reflected by the mirror I6, and passes through the perovskite film 11 of the measured object. The perovskite film is coated on the glass substrate and placed in the heatable carrier 10. The heatable carrier 10 is a frame structure, surrounded by the perovskite film 11, which can be heated at a constant temperature; the heatable carrier 10 is respectively connected with the temperature control device 21 and the liquid crystal display 22; the object light passe...

Embodiment 2

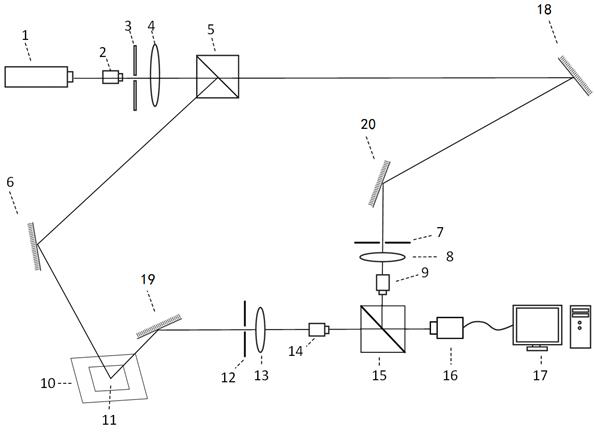

[0028] The method described in this embodiment is the same as that in Embodiment 1, except that the object light O is reflected by the reflector I6, then reflected on the surface of the perovskite film glass substrate, and then reflected by the reflector III19 and enters the third collimation system ( pinhole Ⅲ12, collimating lens Ⅲ13) collimation; reference light R is reflected by mirror Ⅱ18, and then reflected by mirror Ⅳ20, enters the second collimation system (small hole Ⅱ7, collimating lens Ⅱ8) for collimation, and the rest It is the same as the transmission optical system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com