Open system architecture state maintenance system and method of power plant, medium and terminal

An architecture and condition-based maintenance technology, applied in the direction of nuclear methods, structured data retrieval, database management systems, etc., can solve problems such as high price, single function, and mutual incompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

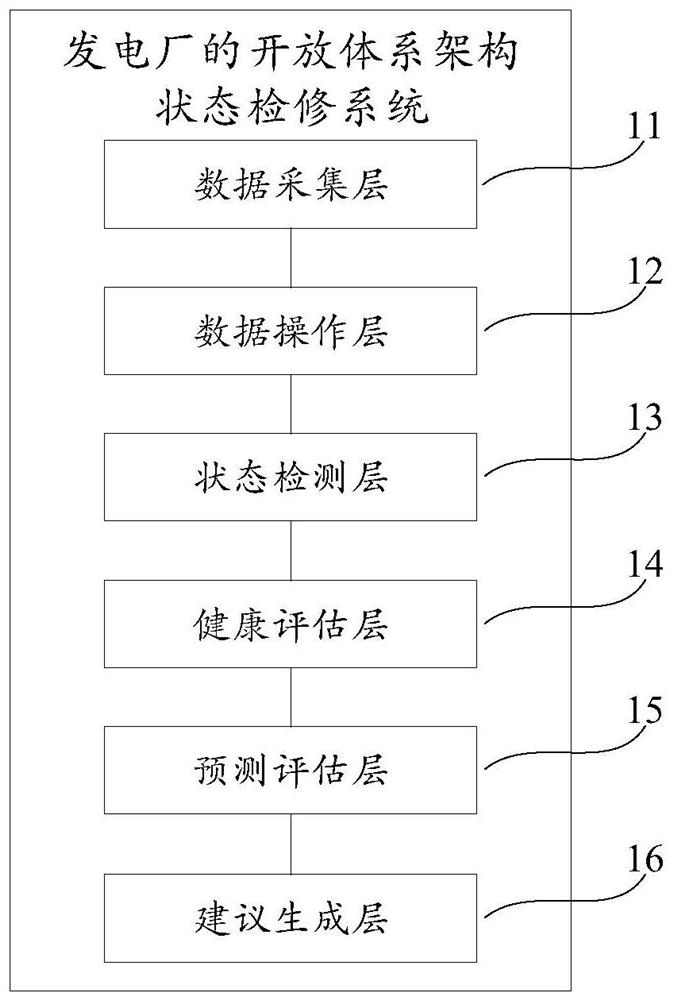

[0028] figure 1It is a schematic structural diagram of an open architecture condition-based maintenance system for a power plant according to an embodiment of the present invention, including: a data collection layer 11, a data operation layer 12, a state detection layer 13, a health evaluation layer 14, a prediction evaluation layer 15, and suggestion generation Layer 16. Wherein, each of the layers uniformly adopts the Open Architecture State-Based Maintenance (OSA-CBM) specification, so as to realize the interchangeability of products from different manufacturers with the same function in each layer. The functions and interrelationships of each layer can be specifically expressed as follows:

[0029] Data Acquisition Layer 11 (Data Acquisition Layer) is used to collect field data of power generation equipment in power plants. Specifically, sensors, smart instruments, and field buses (such as profibus, FF, CAN, etc.) can be used to connect to the site for data collection. ...

Embodiment 2

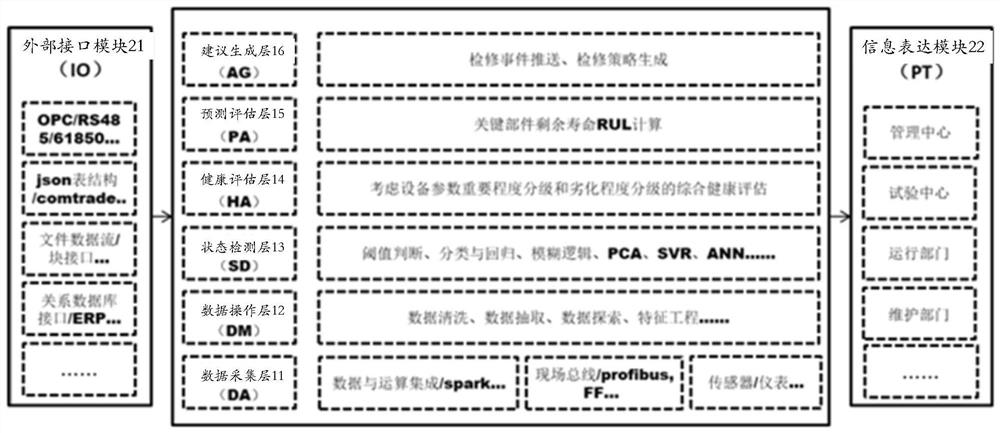

[0053] figure 2 Shown is a schematic structural diagram of an open architecture condition-based maintenance system for another power plant proposed by the present invention, which includes a data acquisition layer 11, a data operation layer 12, a state detection layer 13, a health evaluation layer 14, a prediction evaluation layer 15 and suggestion generation Layer 16 is similar to that described above, so it will not be repeated here. The system also includes an external interface module 21 and an information expression module 22, specifically described as follows:

[0054] The external interface module 21 (IO) is used to realize the communication between various layers of the system and between the system and the outside. Specifically, the open architecture condition maintenance system of the power plant acquires the operating data of the power plant and its electrical system through real-time interfaces such as OPC, RS485, and IEC61850; uses JSON table structure or Comtra...

Embodiment 3

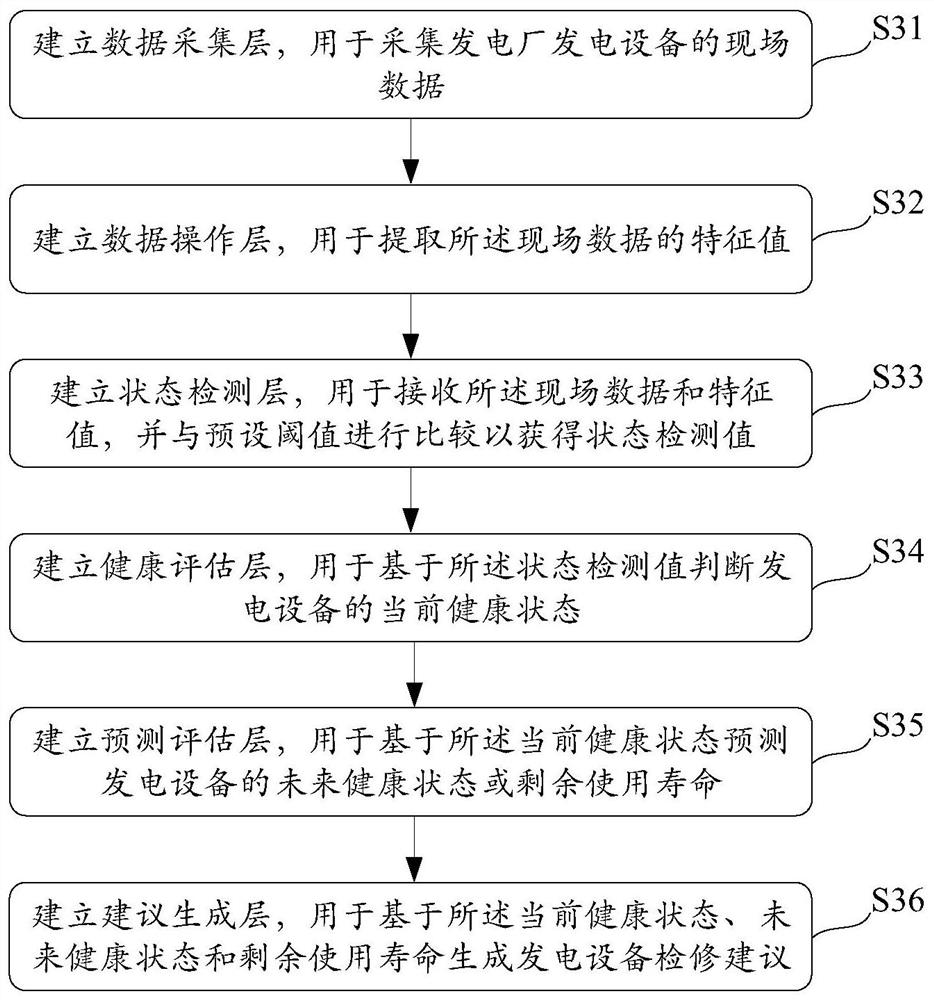

[0057] image 3 It is a schematic flow chart of a design method of an open architecture condition-based maintenance system of a power plant according to an embodiment of the present invention, including: step S31, establishing a data collection layer for collecting field data of power plant power generation equipment; step S32, establishing a data operation Layer, used to extract the characteristic value of the field data; step S33, establish a state detection layer, used to receive the field data and characteristic value, and compare with the preset threshold value to obtain the state detection value; step S34, establish a health The evaluation layer is used to judge the current health state of the power generation equipment based on the state detection value; step S35, establishing a prediction evaluation layer, which is used to predict the future health state and remaining service life of the power generation device based on the current health state; step S36, A suggestion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com