Transformer with amorphous iron core with circular section and protective box

A technology of amorphous iron core and circular cross-section, which is applied in the field of transformer manufacturing, can solve the problems of lower product competitiveness, product discharge, and high cost, and achieve strong short-circuit resistance, reduced iron core weight, and good insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. A preferred embodiment of the invention is shown in the drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. Rather, these embodiments are provided so that the disclosure of the present invention will be thorough and complete.

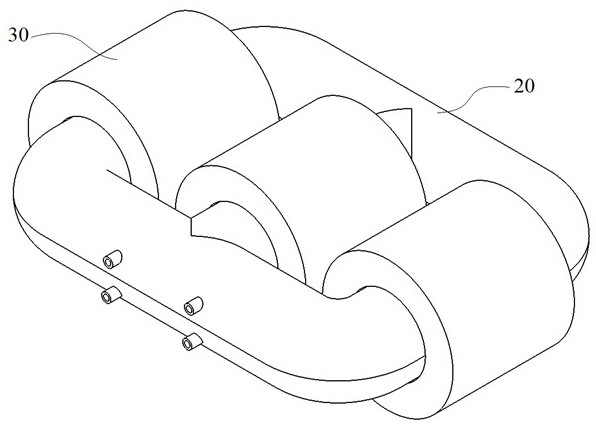

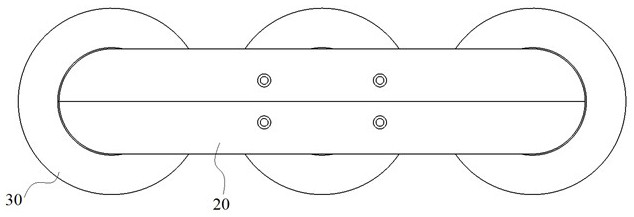

[0026] see Figure 1-Figure 3 The transformer shown in the circular section amorphous iron core with a protective box includes an iron core 10, a protective box 20 and a coil 30. The protective box 20 is sleeved on the iron core 10, and the coil 30 is wound on the protective box 20 to form Amorphous alloy transformer body.

[0027] The iron core 10 includes an inner frame 11 and an outer frame 12. There are 2-4 inner frames 11, and every two inner frames 11 are arranged adjacent to each other. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com