Forming device for spacecraft fairing production

A molding device and fairing technology, applied in the aerospace field, can solve the problems of increased assembly time, large quality, large volume, etc., and achieve the effects of convenient work, convenient adjustment, and convenient assembly work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

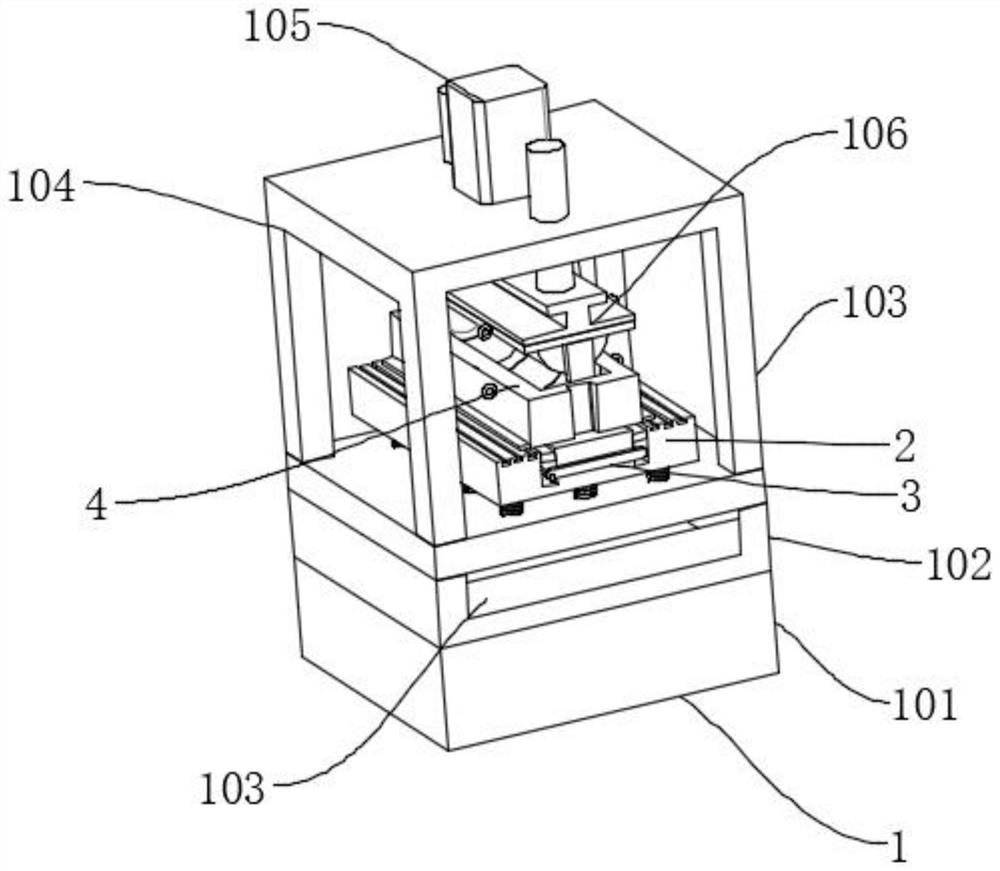

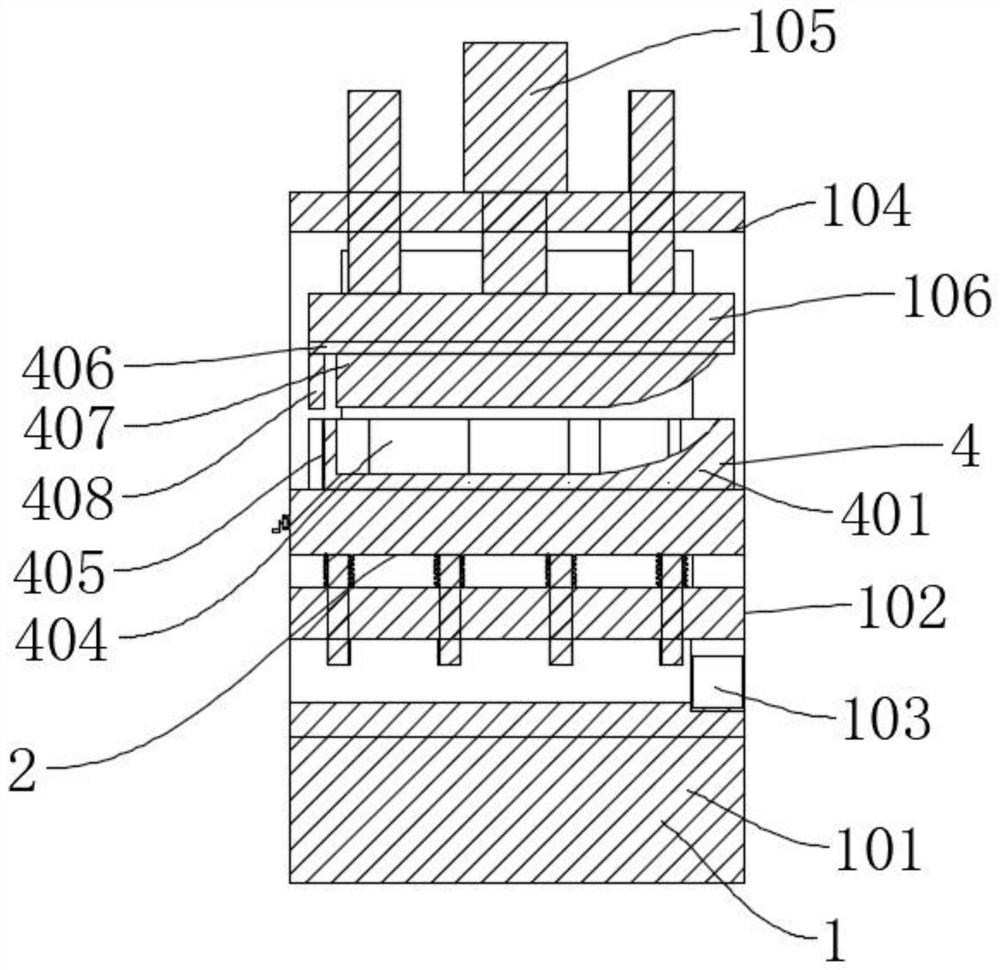

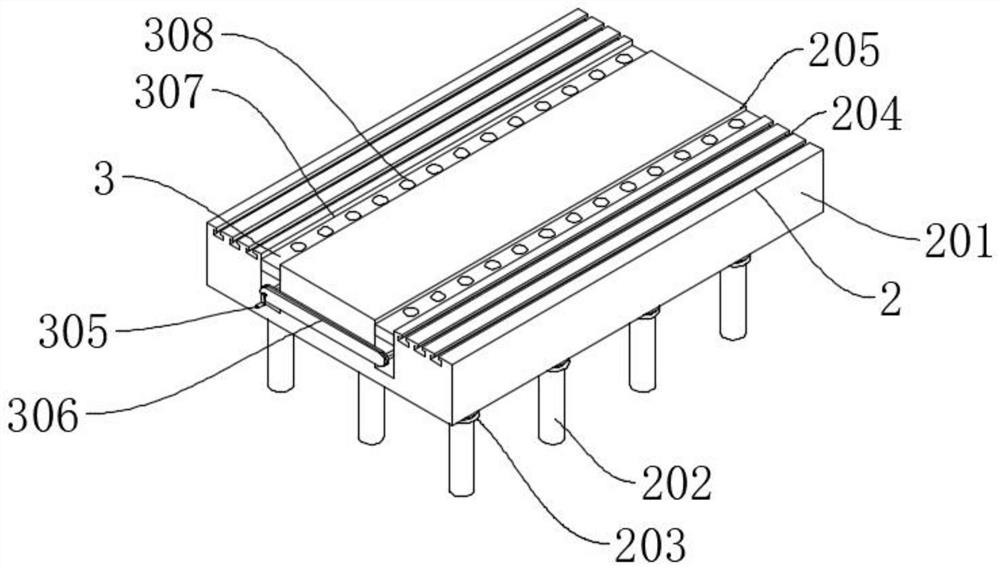

[0034] Such as Figure 1-7As shown, a molding device for the production of spacecraft fairings includes a molding mechanism 1 and a molding die 4. The molding mechanism 1 is mainly composed of a base 101, a mounting frame 102, a frame 104, a hydraulic cylinder 105, and a pressing plate 106. , the top of the base 101 is fixedly installed with an installation frame 102, the top of the installation frame 102 is connected with a frame 104 by bolts, the top of the frame 104 is connected with a hydraulic cylinder 105 by bolts, and the output end of the hydraulic cylinder 105 is connected with a pressure plate 106 by bolts. The frame 102 is a back-type structure, and the top is provided with several through holes 1021, and the front end of the mounting frame 102 is rotatably connected with a storage box 103, so that the storage box 103 can be used to store tools and work notebooks, which facilitates work and saves time. Including a support mechanism 2, the support mechanism 2 include...

Embodiment 2

[0036] Such as Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the pressing plate 106 adopts an I-shaped structure, the two ends of the top of the pressing plate 106 are connected with the front body guide column 11 by screws, and the upper end of the front body guide column 11 passes through the frame 104, and Slidingly connected with the frame 104, such setting increases the strength and stability of the pressing plate 106.

[0037] In the above structure, when in use, the hydraulic cylinder 105 can be activated, the hydraulic cylinder 105 drives the pressing plate 106 to descend, the pressing plate 106 drives the connecting plate 406 to descend, the connecting plate 406 drives the forming convex body 407 to descend, and the forming convex body 407 squeezes the material, so that the material Molding in the cavity between the molding convex body 407 and the molding groove 404, when assembling the molding mold 4, first use the crane to lift the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com