Manufacturing method of ramp steel box girder

A manufacturing method and technology of steel box girders, which are applied in the field of steel box girder manufacturing, can solve problems such as difficult control of welding deformation, difficulty in connecting beam sections, and difficulty in blanking, so as to achieve the effect of eliminating welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

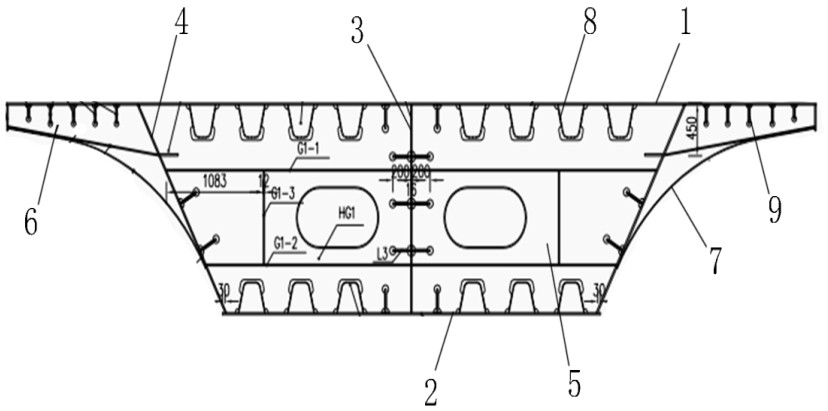

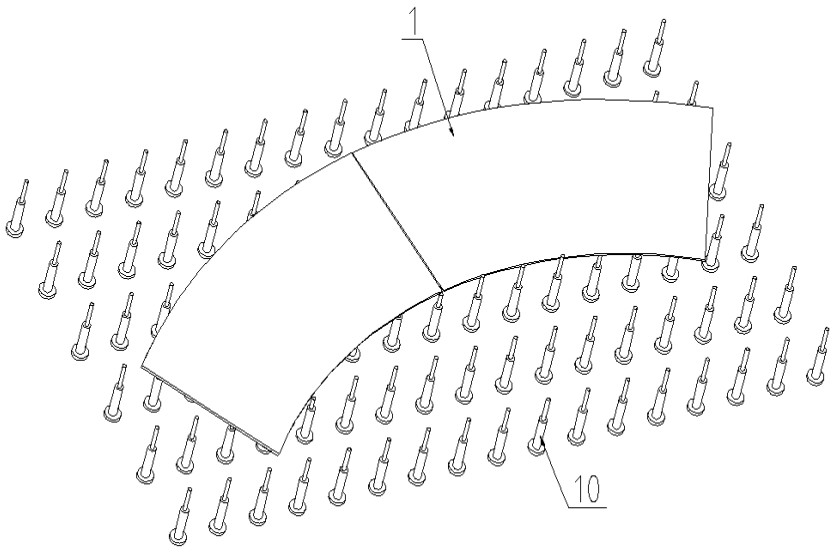

[0035] In a bridge construction project, the main bridge adopts a long-span steel box girder structure. In order to maintain the consistency of the bridge body connection, the ramp approach bridges at both ends of the bridge also adopt a steel box girder structure. figure 1 As shown, the ramp steel box girder includes a bridge deck 1 , a bottom deck 2 , a middle web 3 , a side web 4 , a diaphragm 5 , a cantilever plate 6 and a decorative plate 7 . The ramp steel box girder has a spiral shape as a whole. For the convenience of manufacture and installation, the ramp steel box girder is manufactured in sections.

[0036] A method for manufacturi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com