Magnetic particle grinding machine and method suitable for solid surfaces of crankshafts and non-standard shafts

A crankshaft and standard shaft technology, which is applied in the field of magnetic particle grinders on the surface of crankshafts and non-standard shafts, can solve the problems of limited effective processing area of grinding wheels and abrasive belts, expensive equipment, complex structure, etc., to avoid processing limitations, The effect of high work efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention are further described below, but are not intended to limit the scope of the present invention:

[0036] Example:

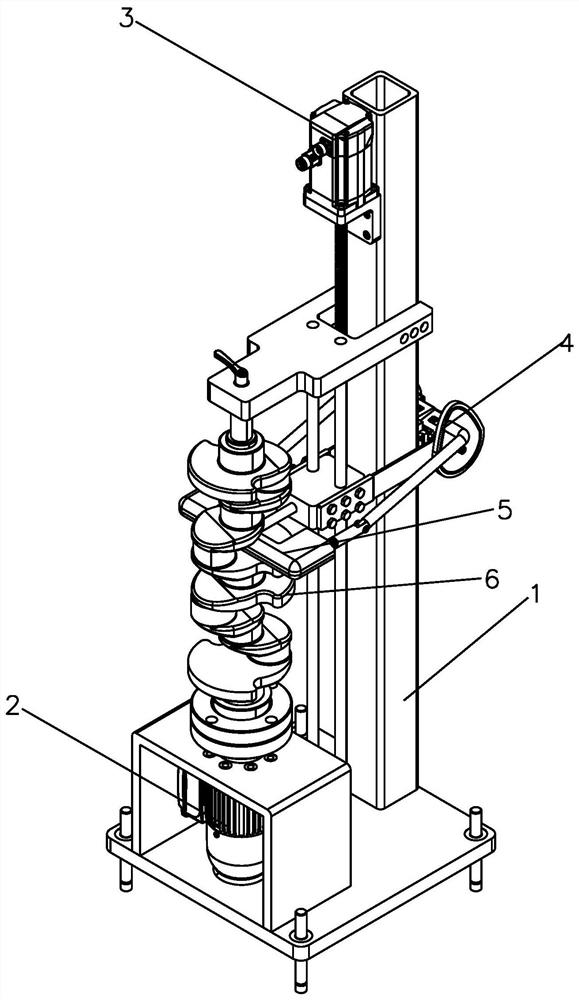

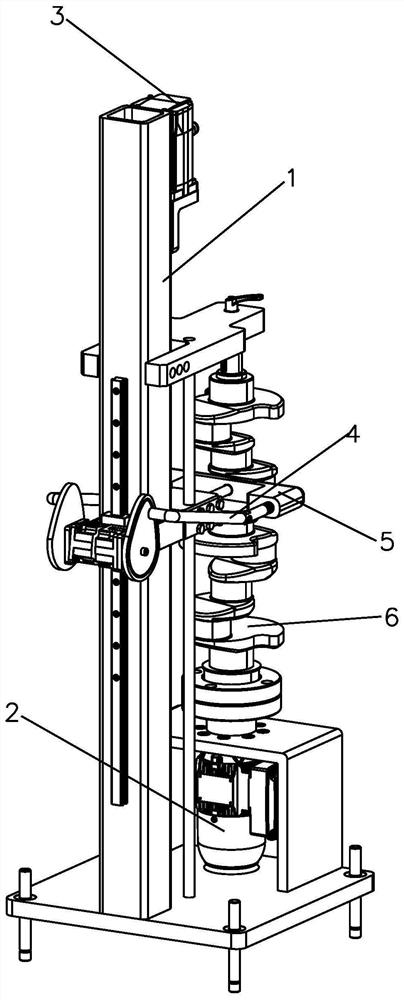

[0037] like figure 1 , figure 2 As shown in the figure, a magnetic particle grinding machine suitable for solid surfaces of crankshafts and non-standard shafts includes a frame 1 and a driving device 2, a lifting device 3, a magnetic particle grinding follower 4 and a magnetic brush 5 installed on the frame 1. .

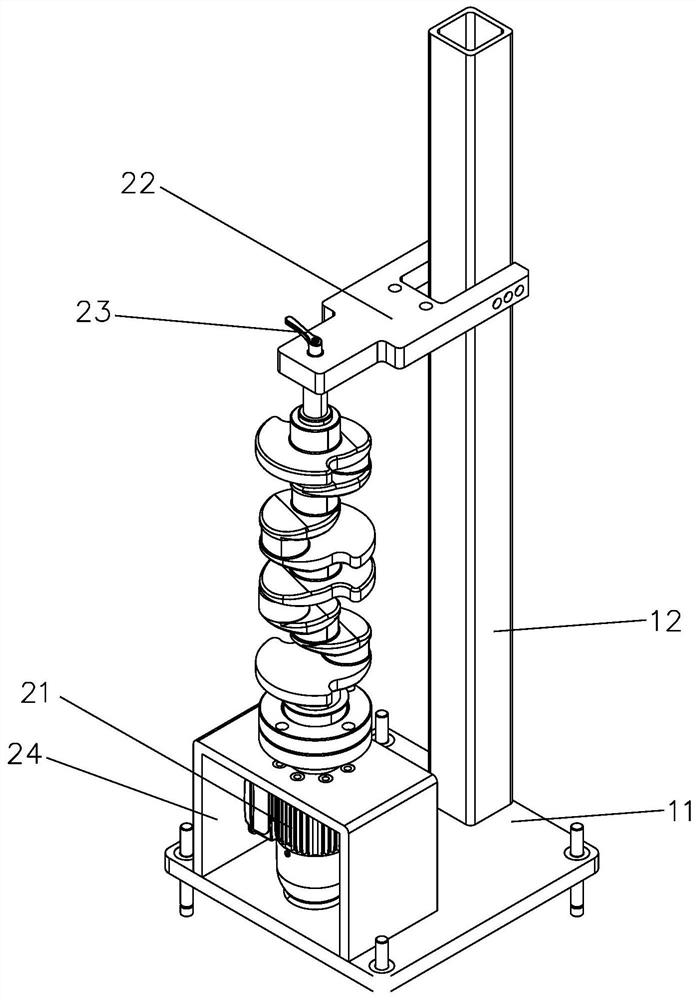

[0038] like Figure 1-4 As shown, the rack 1 includes a bottom platform 11, a column 12 and a slide rail 13; the bottom platform 11 is a platform parallel to the horizontal plane, the column 12 is vertically and vertically fixed on the bottom platform 11, and the slide rail 13 is vertically fixed on the column. 12. The slide rail 13 is perpendicular to the bottom platform 11.

[0039] like image 3 As shown, the driving device 2 includes a driving motor 21 , an upper support member 22 , a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com