Cable trench inspection robot and control system thereof

A control system and cable trench technology, applied in the field of intelligent robots, can solve the problems such as the inability of inspection robots to achieve automatic inspection, the narrow and complex cable trench tunnels in substations, etc., and achieve the effects of strong load capacity, small size and flexible movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

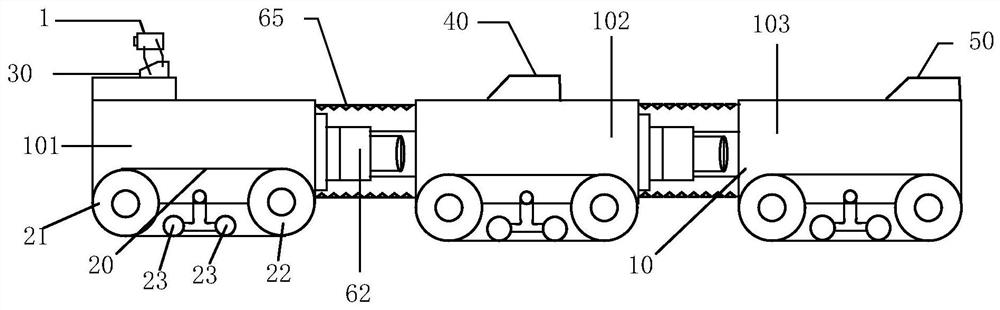

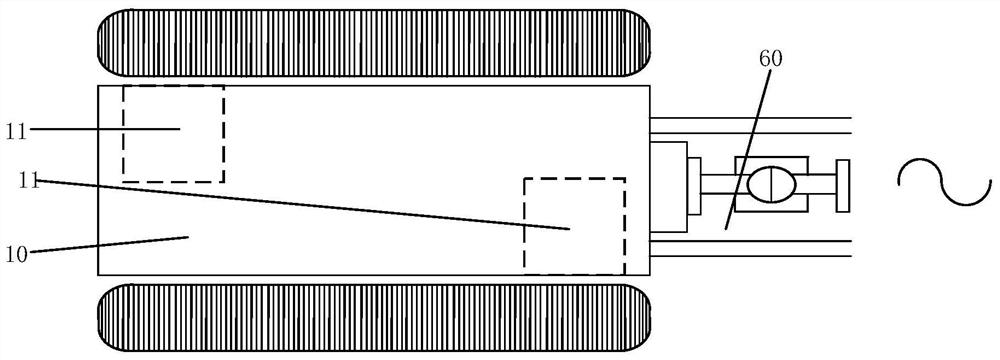

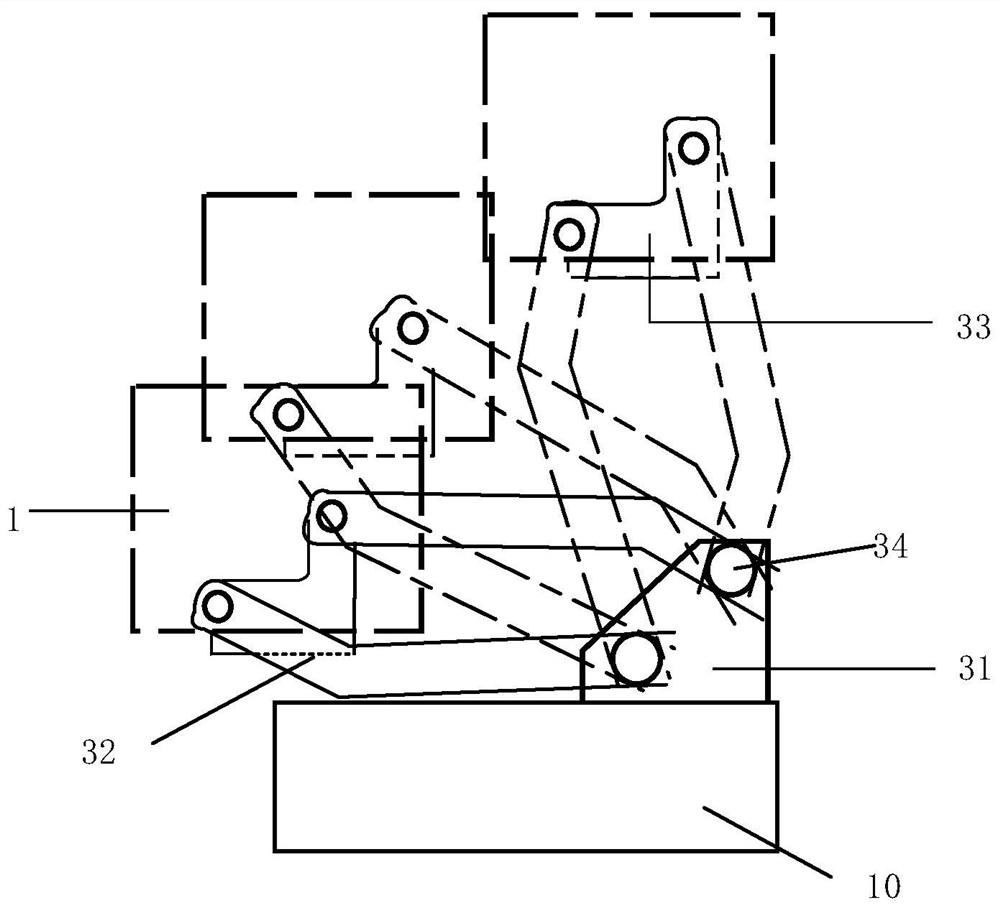

[0036] figure 1 It is a schematic structural diagram of a robot for inspecting cable trenches according to an embodiment of the present invention, figure 2 It is a structural schematic diagram of the installation of the robot drive motor for inspection of the cable trench described in the embodiment of the present invention, image 3 It is a structural schematic diagram of the lifting and lowering of the robot pan-tilt for inspecting the cable trench according to the embodiment of the present invention.

[0037] Such as figure 1 As shown, the embodiment of the present invention provides a robot for inspecting cable trenches, including at least three joint mechanisms 10, each joint mechanism 10 is provided with at least two drive motors 11, and the bottom end of each joint mechanism 10 is provided with There is a walking mechanism 20 for driving the joint mechanism 10. The three joint mechanisms 10 are respectively the first joint mechanism 101, the second joint mechanism 10...

Embodiment 2

[0054] Figure 5 It is a frame diagram of the control system of the robot for inspecting the cable trench according to the embodiment of the present invention.

[0055] Such as Figure 5 As shown, the embodiment of the present invention also provides a control system based on the above-mentioned inspection robot for cable trenches, including a first controller 1, a second controller 2, an output module 3, a power module 4, a status monitoring module 5, Gas detection module 6 and temperature detection module 7, state monitoring module 5 includes pan-tilt drive sub-module 8 and camera sub-module 9, output module 3, power supply module 4, pan-tilt drive sub-module 8, gas detection module 6 and temperature detection module 7 are all connected to the first controller 1, and the second controller 2 is connected to the first controller 1 and the camera sub-module 9 respectively.

[0056] In the embodiment of the present invention, the output module 3, the power module 4, the pan / ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com