Dust cover rotary cutting device of automobile shock absorber

A technology of automobile shock absorber and rotary cutting device, which is applied to household components, other household appliances, household appliances, etc., can solve the problems of long clamping time, low processing efficiency, time-consuming and labor-intensive, etc., to improve processing efficiency, hold Better tightening effect and lower labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

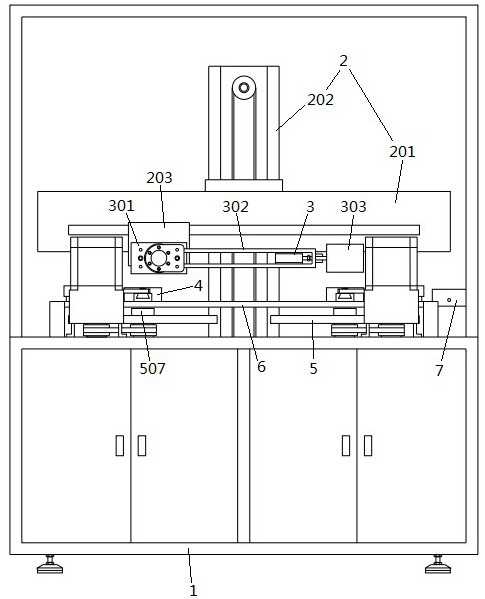

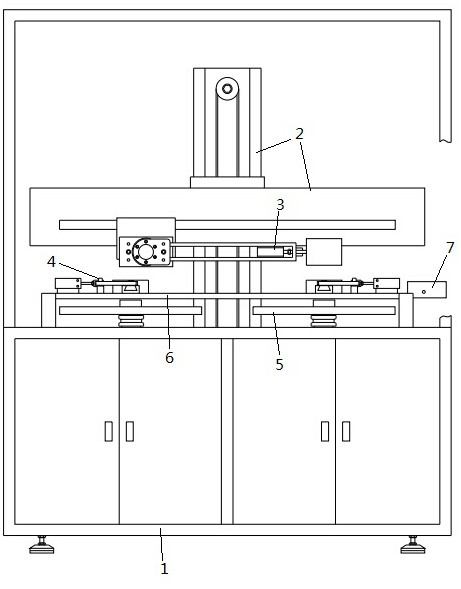

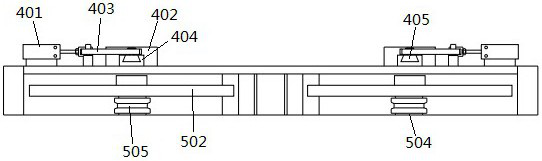

[0035] Embodiment 1: as Figure 1-7As shown, a rotary cutting device for a dust cover of an automobile shock absorber includes a frame 1, a linear drive module 2, a grabbing mechanism 3, an engagement mechanism 4 and a rotary cutting mechanism 5; the linear drive module 2 includes The X-axis linear module 201 and the Z-axis linear module 202, the Z-axis linear module 202 is arranged on the frame 1, the X-axis linear module 201 is connected to the Z-axis linear module 202; Swing driving device, swing arm 302 and manipulator 303, the swing driving device is connected to the X-axis linear module 201, the swing arm 302 is connected to the swing driving device and kept in a horizontal state, and the manipulator 303 is set on the swing arm 302 away from the swing drive One end of the device; the rotary cutting mechanism 5 is symmetrically arranged on the frame 1, which includes a rotary drive device, a rotating disc 502, a linear module 507 for advancing and retreating a knife, and ...

Embodiment 2

[0036] Embodiment 2: This embodiment is a further improvement of Embodiment 1. The main improvement is that when Embodiment 1 is in use, the manipulator 303 needs to be stretched into the blow molding machine 9 to take materials, because the dust cover 8 is lighter and It is easy to shake, so the dust cover 8 is easy to tilt when it is taken off, which causes the slits at both ends of the dust cover 8 to tilt during rotary cutting, thereby affecting product quality; and in the present embodiment, the above-mentioned defects can be avoided. Specifically:

[0037] One end of the support platform 6 is provided with an adjustment seat 7 for adjusting the posture of the material; the top of the adjustment seat 7 is provided with a trough 701, and a vacuum port 702 is provided in the trough 701, and the vacuum port 702 runs through the adjustment seat 7 And connect the vacuum generator in the box body by pipeline; Described adjustment seat 7 is two adjustment blocks 703 that left an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com