Polypropylene composition and preparation method thereof

A polypropylene composition and copolymer technology, applied in the field of polypropylene composition and its preparation, can solve the problems of complicated preparation process, unfavorable for industrialized large-scale production, etc., achieve high electrical conductivity, excellent mechanical properties, and improve electrical conductivity. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

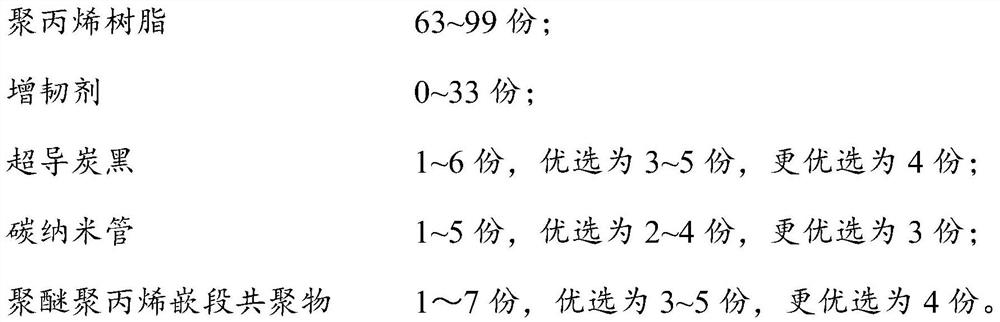

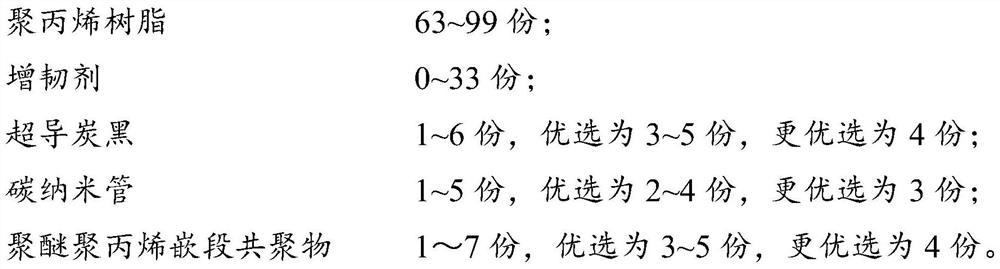

Method used

Image

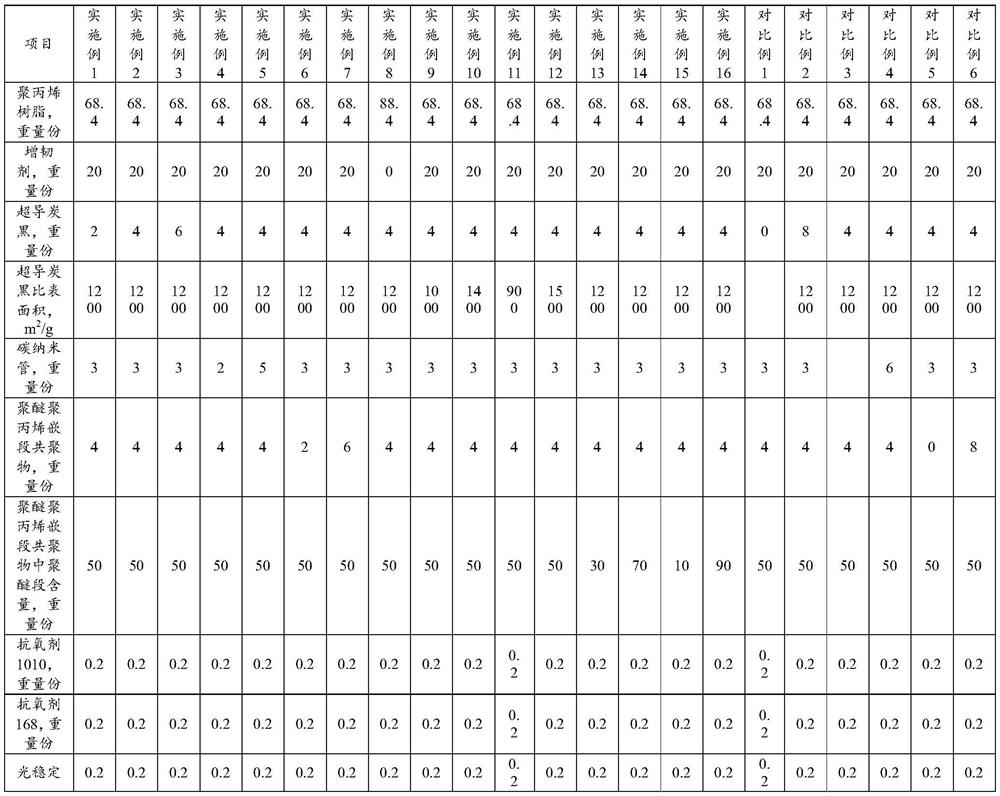

Examples

Embodiment Construction

[0026] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples. Those skilled in the art should understand that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

[0027] In the examples, the experimental methods used are conventional methods unless otherwise specified, and the materials and reagents used are commercially available unless otherwise specified.

[0028] The raw material source of following embodiment and comparative example is described as follows:

[0029] Polypropylene resin: Sinopec, copolymerized polypropylene resin, according to ASTM D1238-2010 standard, at 230°C, under a load of 2.16kg, its melt mass flow rate is 30g / 10min;

[0030] Toughener: Dow Chemical, ethylene-butylene copolymer, density 0.862g / cm 3 , according to the AST...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt mass flow rate | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melt mass flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap